Elastic upper-loader of wagon in railway

A railway freight and vehicle technology is applied in the field of elastic upper and side bearing of railway freight vehicles, which can solve the problems of poor running quality and large torsional stiffness, and achieve the effects of improving running quality, increasing torsional deformation, and using coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

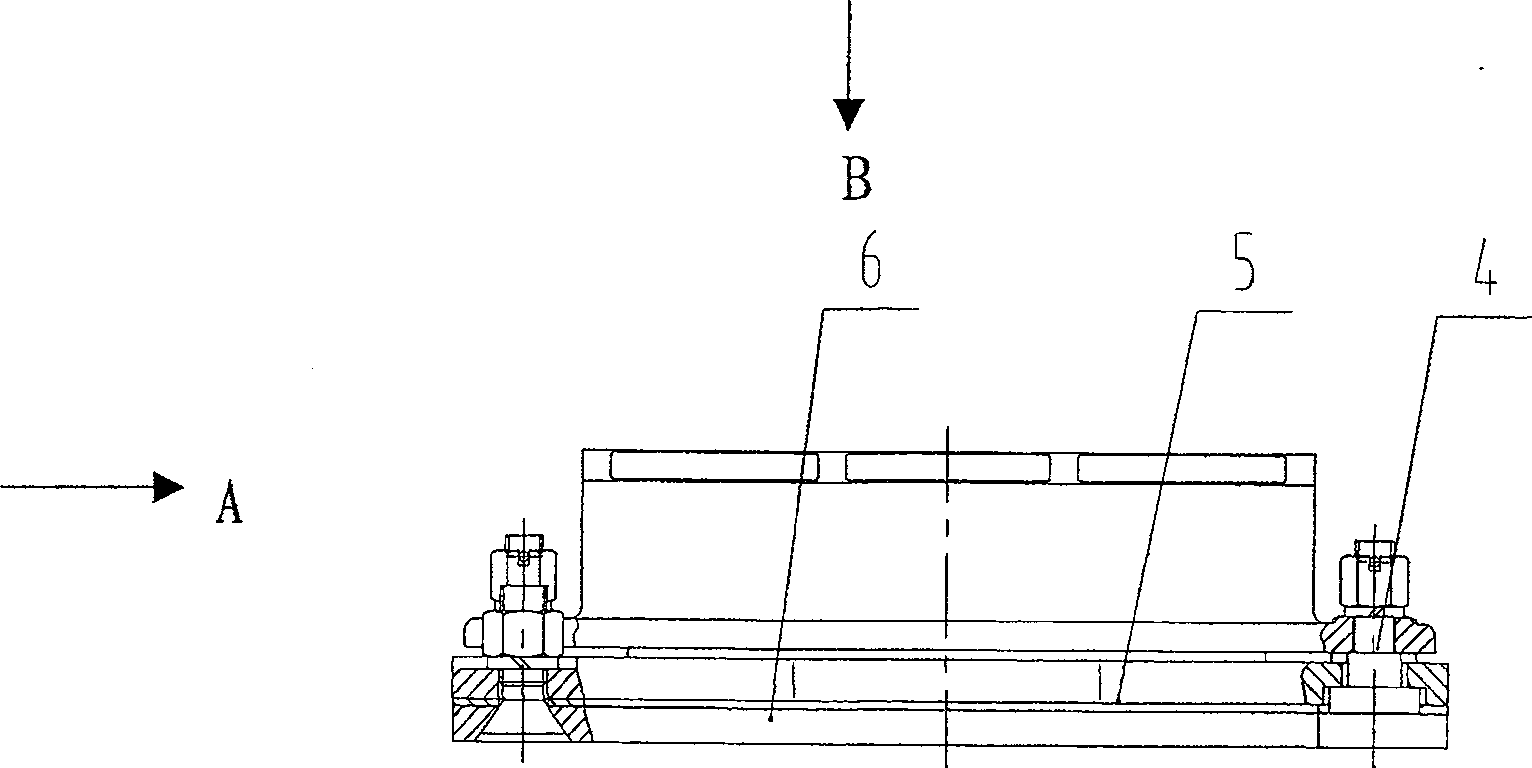

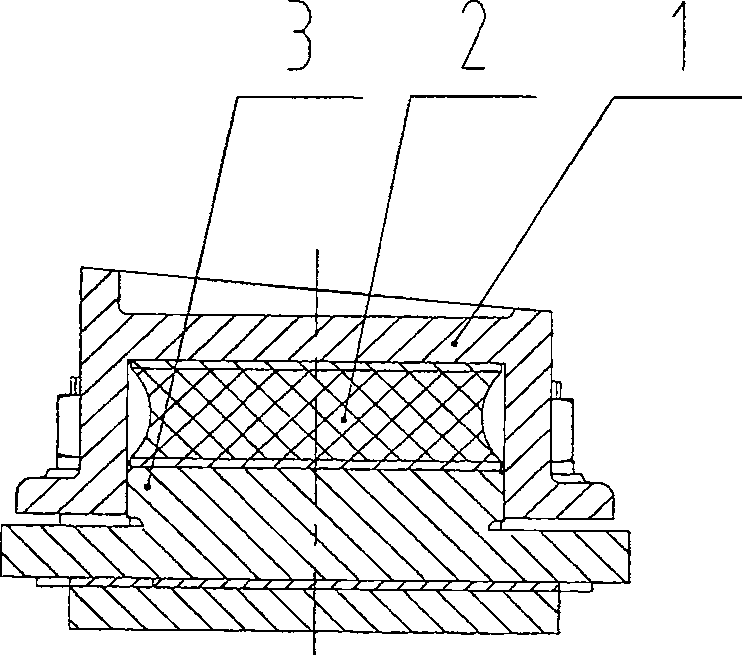

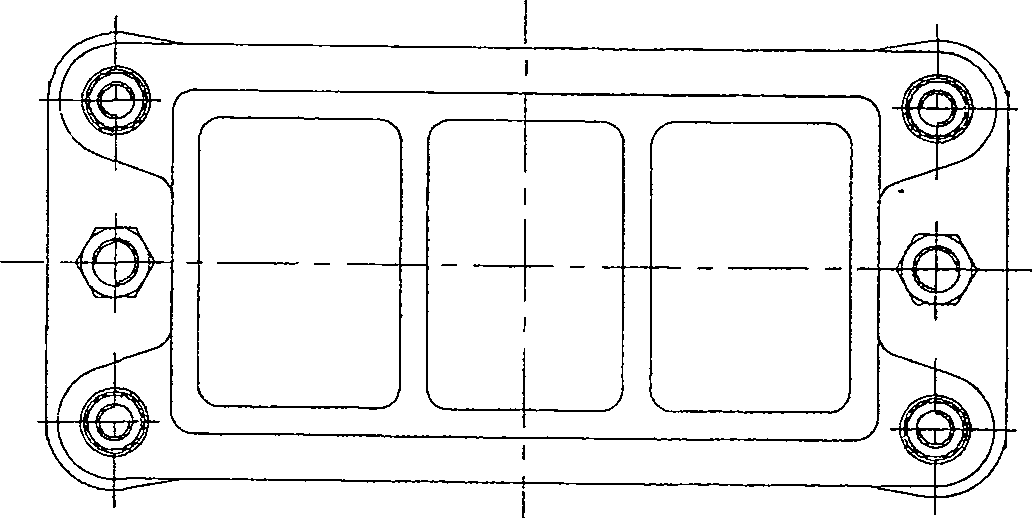

[0022] see figure 1 — Figure 12 , the present invention includes a side bearing seat 1, a side bearing body 2 and a side bearing bottom plate 3. The key technology is: the side support seat 1 has a groove 1.3 that runs through to the bottom surface, the center of the side support base plate 3 is a boss 3.1 that matches the groove 1.3, the side support body 2 is located on the boss 3.1, the boss 3.1 and the side support The supporting body 2 is located in the groove 1.3 of the side bearing seat 1 . The side support seat 1 and the side support base plate 3 are connected by limit bolts 4, and there is a vertical gap of 2-5mm between the side support seat 1 and the side support base plate 3. The bottom of the limit bolt 4 is disc-shaped and has a groove, and the top has a pin hole, and the part where the screw rod is connected to the bottom of the bolt is the shoulder 4.1, so that the screw rod is stepped. The bottom of the side bearing base plate 3 is connected with an adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com