Automatic welding compressing apparatus for jointed board of container

An automatic welding and pressing device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to adjust the pressing force uniformly, poor electrical conductivity and heat dissipation performance, poor vision of operators, etc. Good rigidity, good electrical conductivity and heat dissipation, and uniform pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

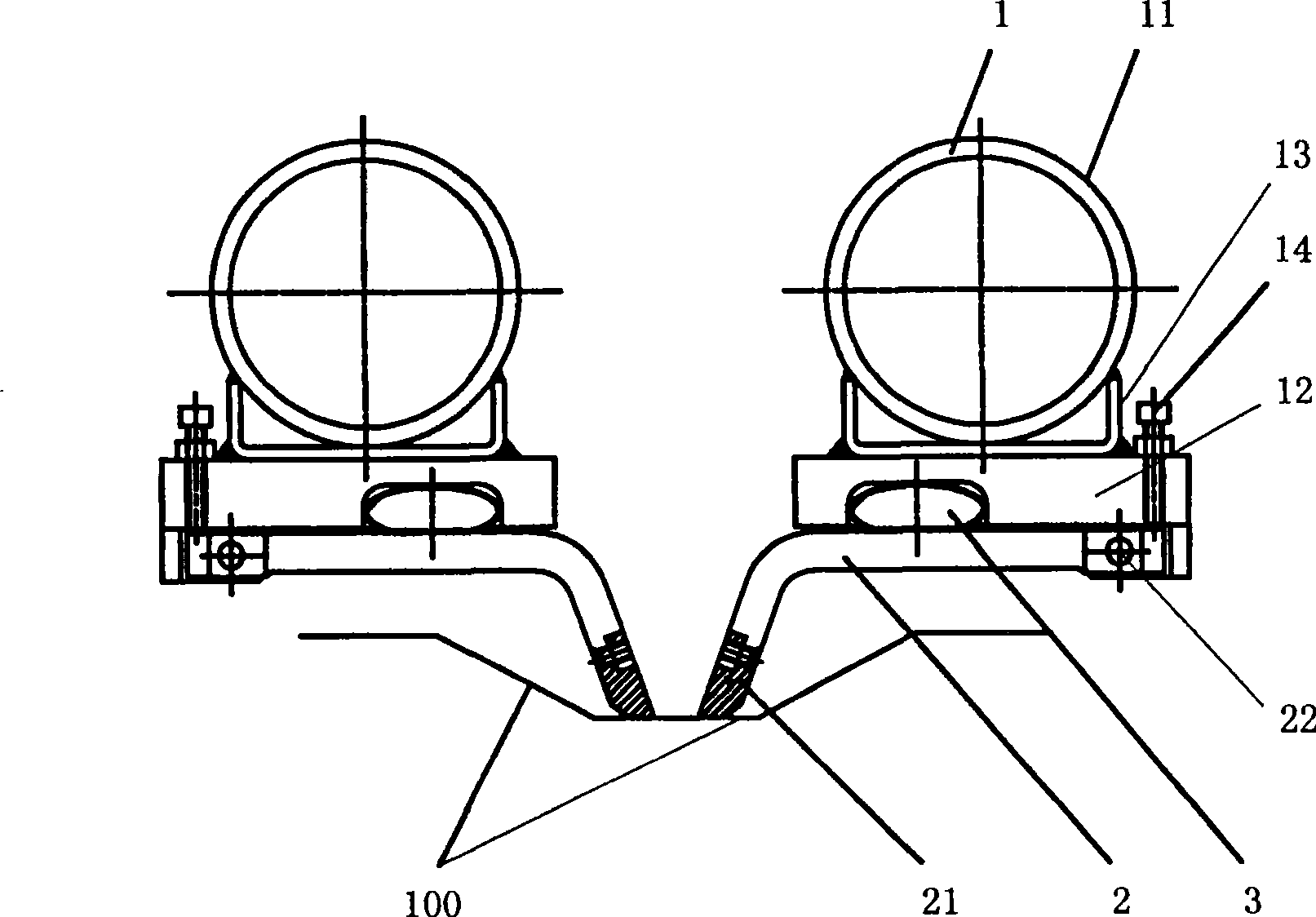

[0022] figure 1 Embodiment 1 of the automatic welding and pressing device for splicing container panels of the present invention is shown. Such as figure 1 As shown, the container panel automatic welding and pressing device includes a pressing frame 1, a presser foot 2 and an airbag 3 of a pressing force adjustment device, the pressing frame 1 extends along the welding direction, and the pressing feet 2 are distributed at intervals and connected to the pressing force On the frame 1, the air bag 3 is arranged between the pressing frame 1 and the presser foot 2 and extends along the pressing frame 1. The rear end of the presser foot 2 is rotatably connected to the pressing frame 1 and can rotate counterclockwise. The presser foot 2. The front end faces the same side of the compression frame 1 and is located under the airbag 3. When the presser foot 2 rotates counterclockwise, the rear end of the presser foot is constrained by the structure of the compression frame 1, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com