Deep channel type oxidation channel wastewater treatment system

A sewage treatment system and oxidation ditch technology, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems that the sewage treatment plant occupies a large area, cannot reproduce the water flow velocity in real time, and the limitations of ditch depth and ditch width, etc. To achieve the effect of expanding sewage treatment capacity, solving the problem of easy sedimentation, and increasing the depth of the ditch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Accompanying drawing is embodiment of the present invention.

[0016] Below in conjunction with accompanying drawing, content of the invention will be further described:

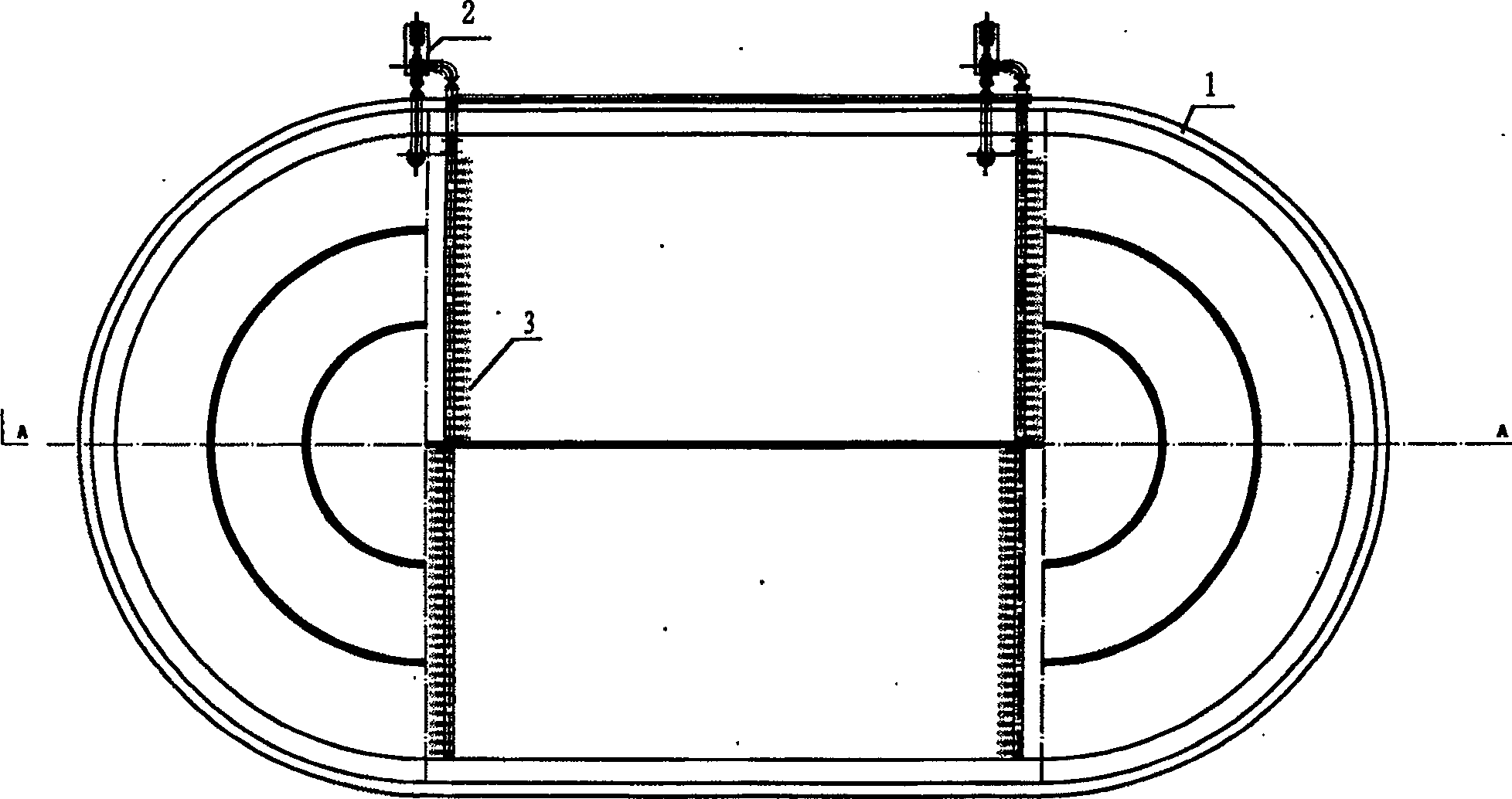

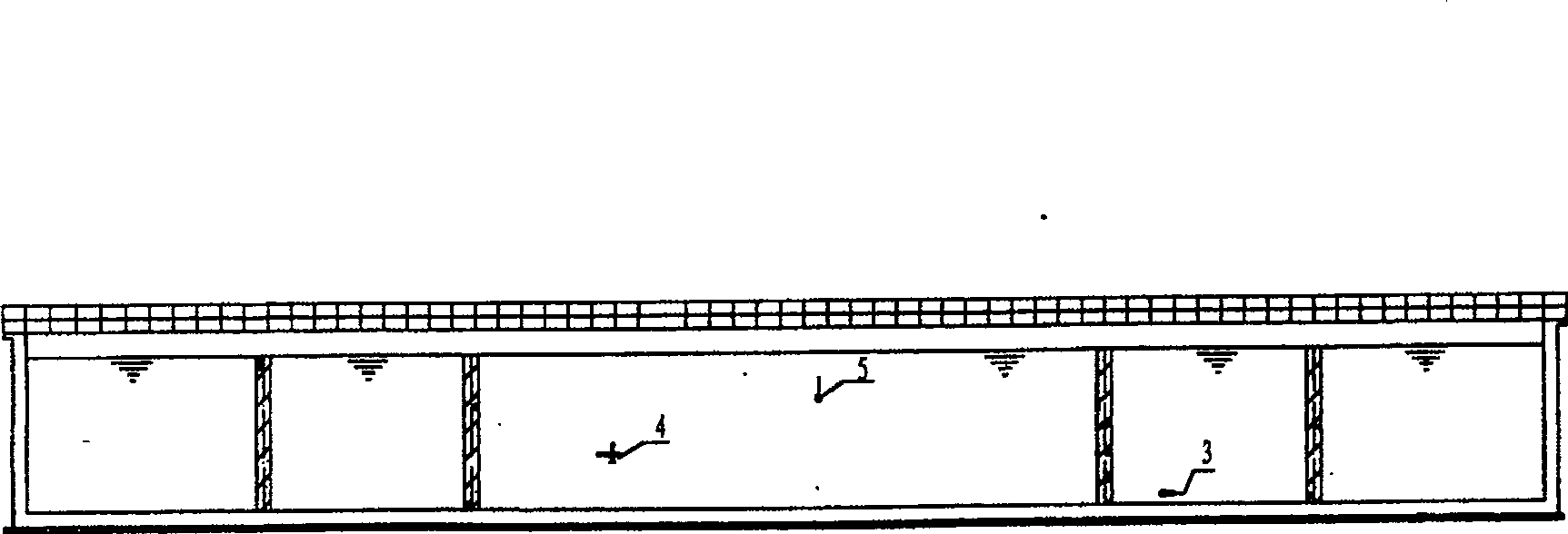

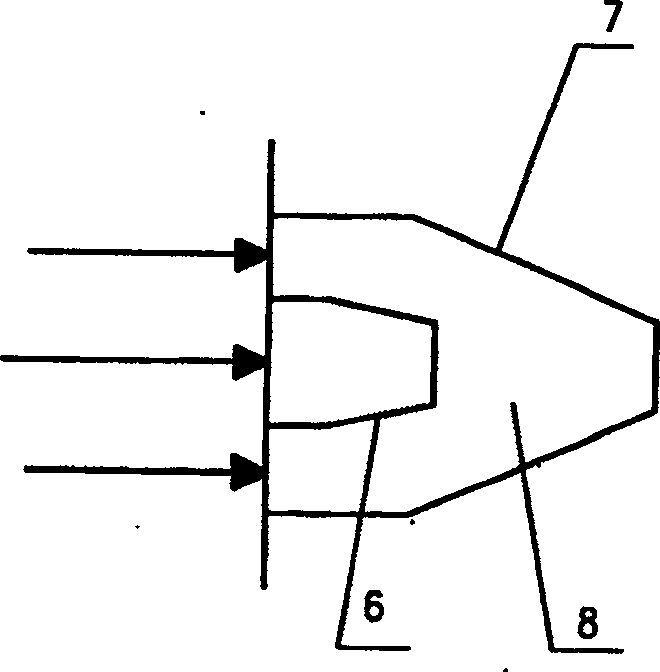

[0017] refer to figure 1 , figure 2 As shown, a deep-ditch oxidation ditch sewage treatment system includes an annular oxidation ditch 1 with a diversion wall in the middle, and a circulating jet water pump 2 connected to an air-supply low-pressure jet aeration device 3 is installed on the ground. An air-supply low-pressure jet aeration device 3 is installed at the bottom, and a real-time online water flow rate and depth measuring device 4 and a dissolved oxygen analyzer 5 are installed in the ditch, and the air-supply low-pressure jet aeration device 3 is changed according to the set control mode. The flow rate of the circulating jet water pump 2 or the air supply fan of the jet aeration device 3, the shape of the oxidation ditch 1 is an elliptical ring, a circular ring or a rectangular ring.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com