Steel rail wearing integrative parameter vehicle-mounted dynamic measuring device and method

A comprehensive parameter and dynamic measurement technology, applied in the direction of measuring devices, railway vehicle shape measuring devices, optical devices, etc., can solve the problems of sampling density, image sensing and acquisition hardware equipment performance limitations, to reduce cost and improve utilization rate and processing efficiency, and overcome the effect that the transfer function is not 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

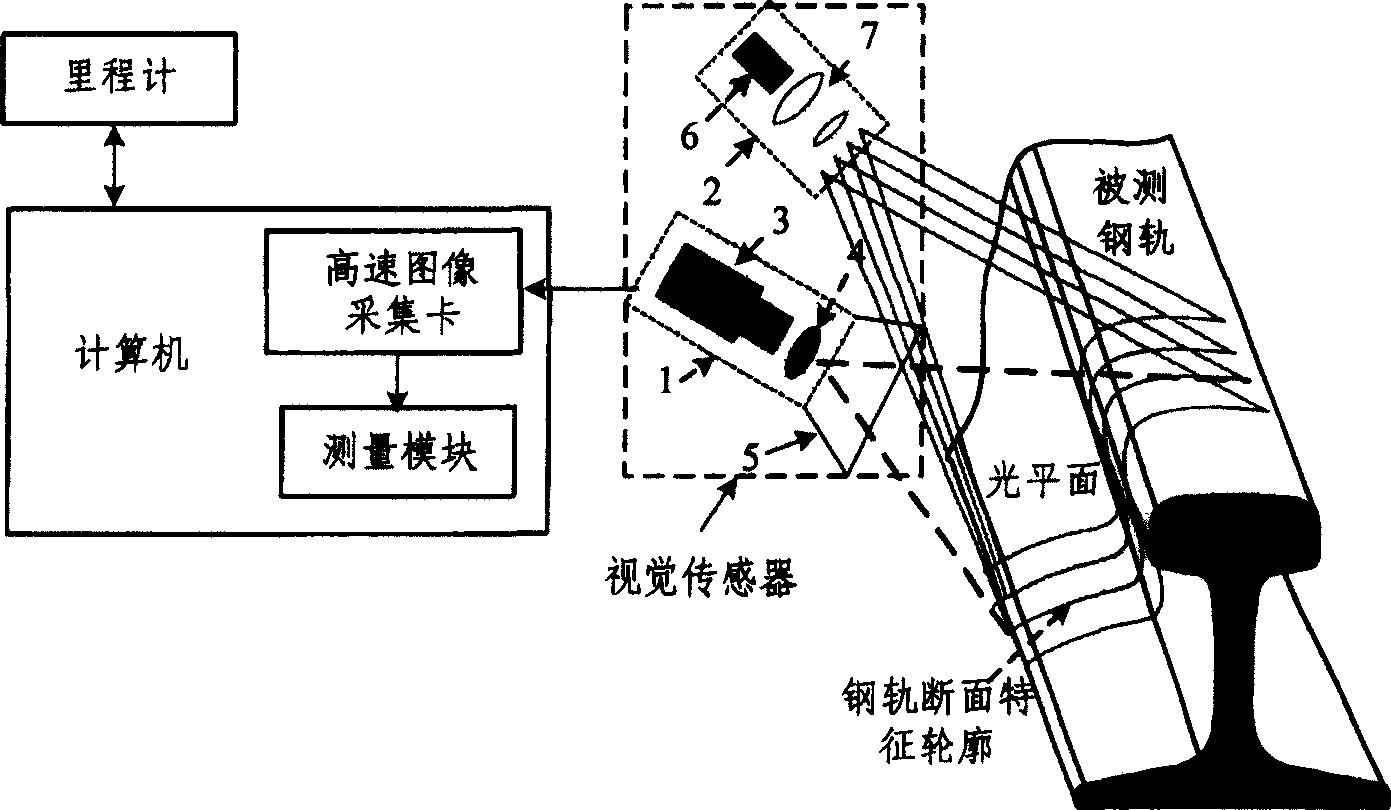

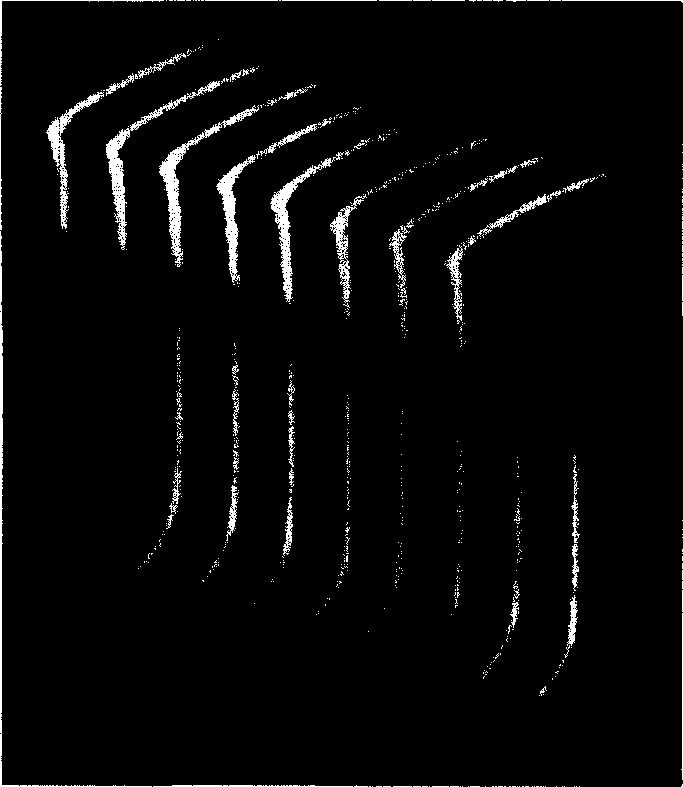

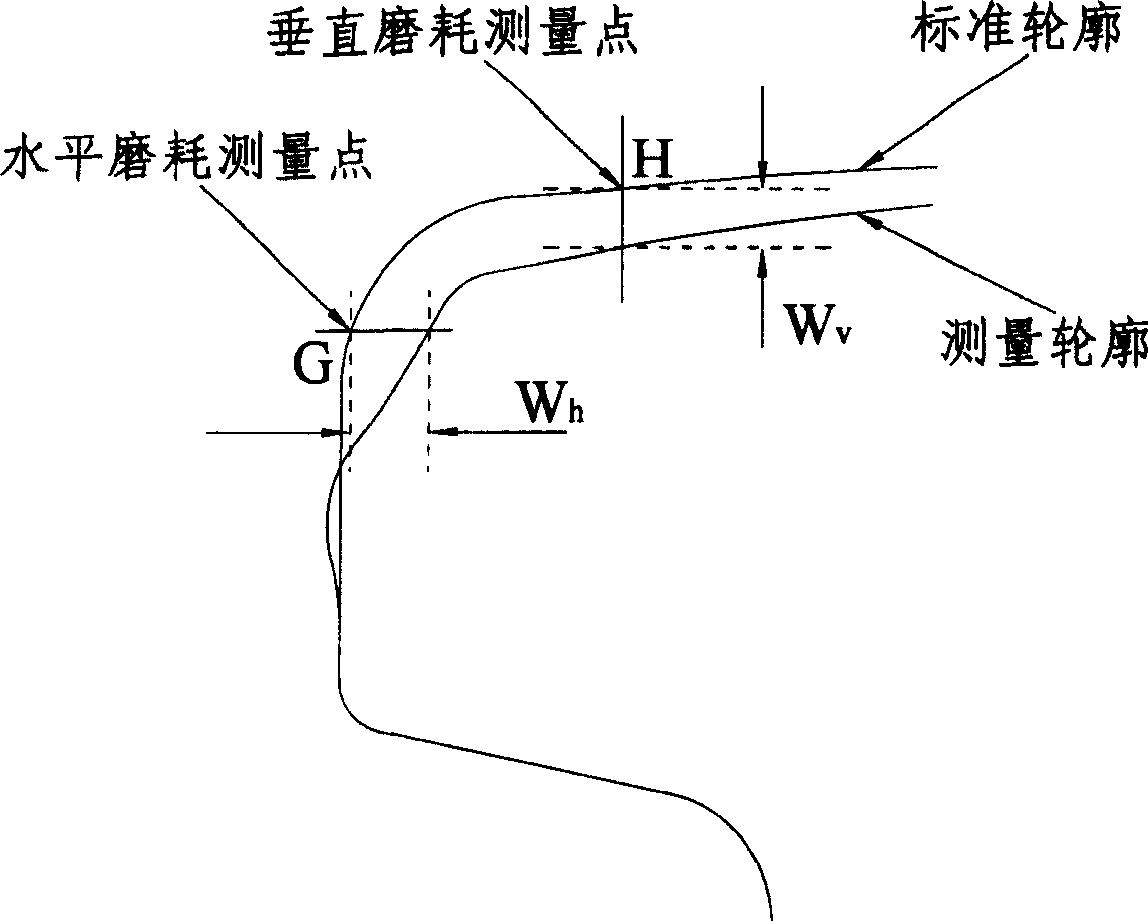

[0028] The vehicle-mounted dynamic measuring device for comprehensive parameters of rail wear provided by the invention, such as figure 1 As shown, it includes a visual sensor, computer, and odometer; generally, the computer is placed in the train compartment, and the computer is equipped with a high-speed image acquisition card and a measurement module. The visual sensor includes a rail section imaging system 1 and a grating projector 2. The rail section imaging system 1 is composed of a high-speed industrial charge coupled device (CCD, Charge Coupled Device) camera 3 , a filter device 4 , and a light shielding device 5 , and the grating projector 2 is composed of a semiconductor laser 6 and an optical system 7 . The grating projector 2 can project more than two light planes perpendicular to the measured rail, the distance between the light planes is known, the angle between the optical axis of the rail section imaging system 1 and the optical axis of the grating projector 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com