Composite stabilizer of metal salt of organic carboxylic acid containing sulfur in use for polymer containing halogen, and application thereof

A technology of composite stabilizer and sulfur organic carboxylic acid, which is applied in the field of chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

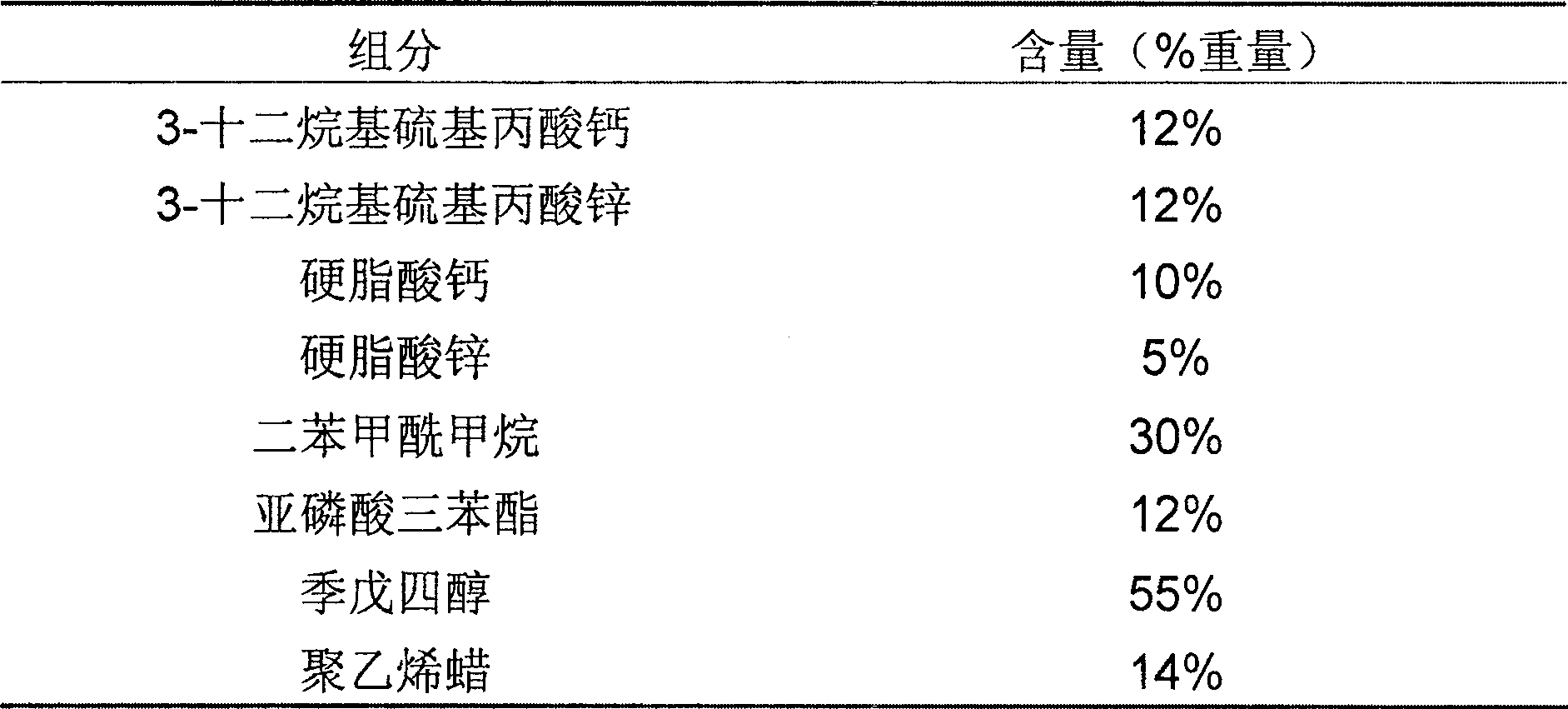

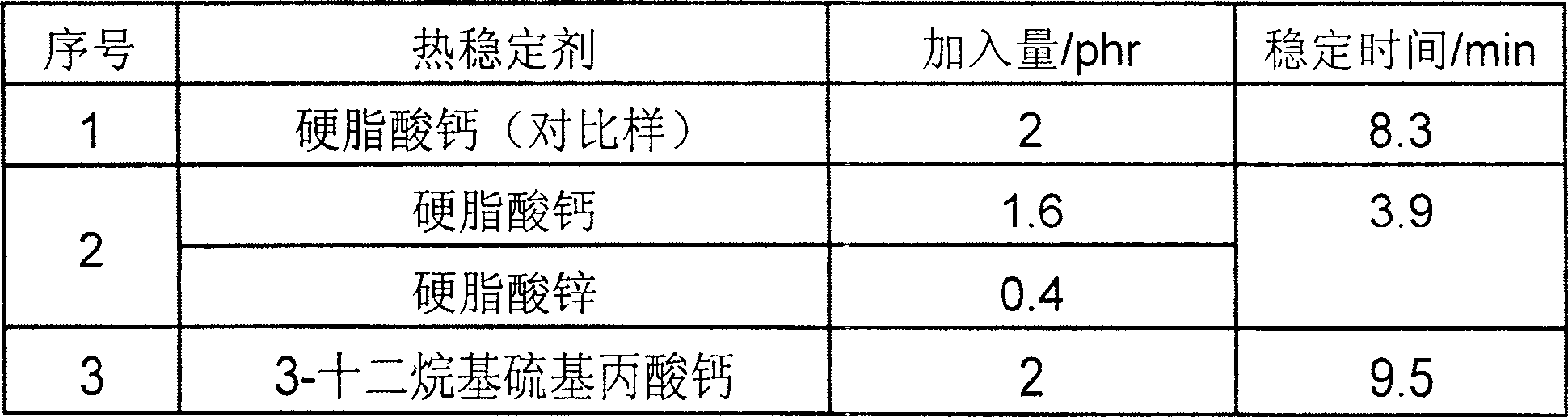

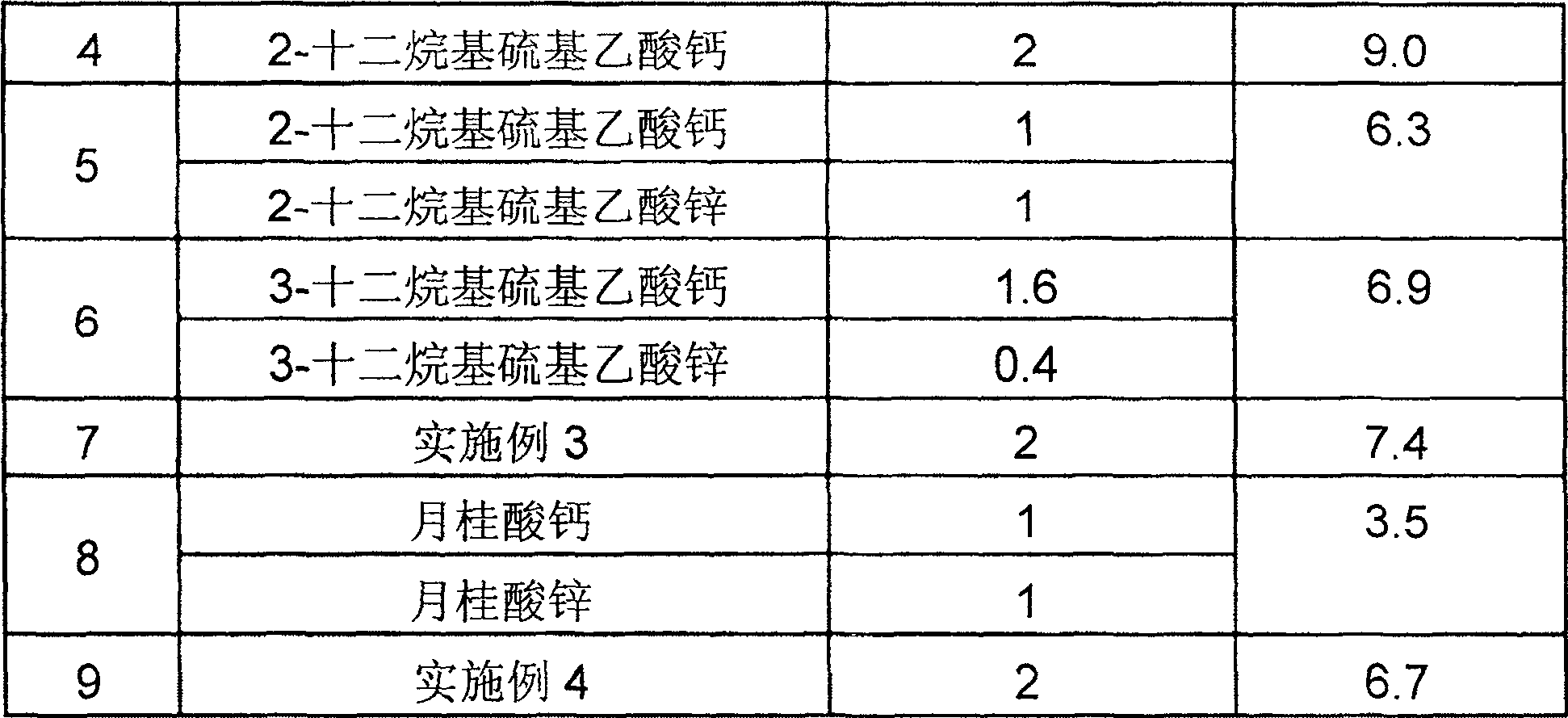

Method used

Image

Examples

Embodiment 1

[0044] Zinc 2-dodecylthioglycolate:

[0045] Add 18.0g (0.782mol) sodium metal into 2000mL methanol and stir for 30min to prepare a sodium methoxide / methanol solution. Under the protection of dry nitrogen, 28.8g (0.313mol) of mercaptoacetic acid was added to the above-mentioned sodium methylate / methanol solution, and after the white precipitate formed was completely dissolved, 2000mL (0.261mol) of 1-bromo-n-dodecane was added dropwise / Ether solution, dropwise, stirred at room temperature for 16h. The reaction solution was poured into 2000 mL of 10% hydrochloric acid solution, separated, the organic layer was washed with water, washed with saturated sodium chloride solution, dried over anhydrous sodium sulfate, and concentrated to obtain colorless 2-dodecylthioacetic acid.

[0046] In a 100mL stainless steel reactor equipped with a stirrer, a thermometer and a heating jacket, add 39g of 2-dodecylthioglycolic acid, melt it at 100°C, start the stirrer and put 2-dodecyl Thiogly...

Embodiment 2

[0048] Calcium 3-Laurylthiopropionate:

[0049] A four-neck round bottom flask is equipped with a reflux condenser, a stirrer, a dropping funnel and a thermometer. Add 0.275mol acrylic acid and 50ml isopropanol into the reaction flask, add dropwise sodium hydroxide solution (0.3mol sodium hydroxide dissolved in 52ml water), and control the temperature between 35°C. Slowly add 0.25mol n-dodecanethiol dropwise, and reflux for 3h after dropping. Add appropriate amount of H to the reaction solution 2 O, then slowly add 0.125mol calcium chloride solution while stirring to carry out metathesis reaction. After the reaction is completed, the reaction product is separated, washed and dehydrated, and then dried under normal pressure at 80°C to obtain white calcium 3-dodecylthiopropionate.

Embodiment 3

[0051] 2-Lauryl laurylthioacetate:

[0052] In a 1000mL stainless steel reactor equipped with a stirrer, a thermometer and a heating jacket, add 195g of 2-dodecylthioglycolic acid, melt it at 90°C, start the stirrer and put 3% hydrogen peroxide, and mix well Finally, add 22.8g of refined mixed light rare earth oxides (wherein the weight of lanthanum oxide accounts for more than 95% of the total weight) to the reaction kettle at 90°C, react at 100°C for 2.5 hours, and release the material after the reaction is completed. After cooling, crush it into >60 US mesh powder to obtain powdery lanthanum 2-dodecylthioacetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com