Single slice waste removing device of high-speed ration type preforming machine and operating procedure thereof

A technology of high-speed rotation and tablet press, which is applied in the direction of making medicines into special physical or ingestible forms, presses, material forming presses, etc., which can solve the problem of low accuracy of rejecting and affecting production costs and efficiency , waste chips mixed into qualified products, etc., to achieve the effect of high accuracy and efficiency of waste rejection, simple and reasonable structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

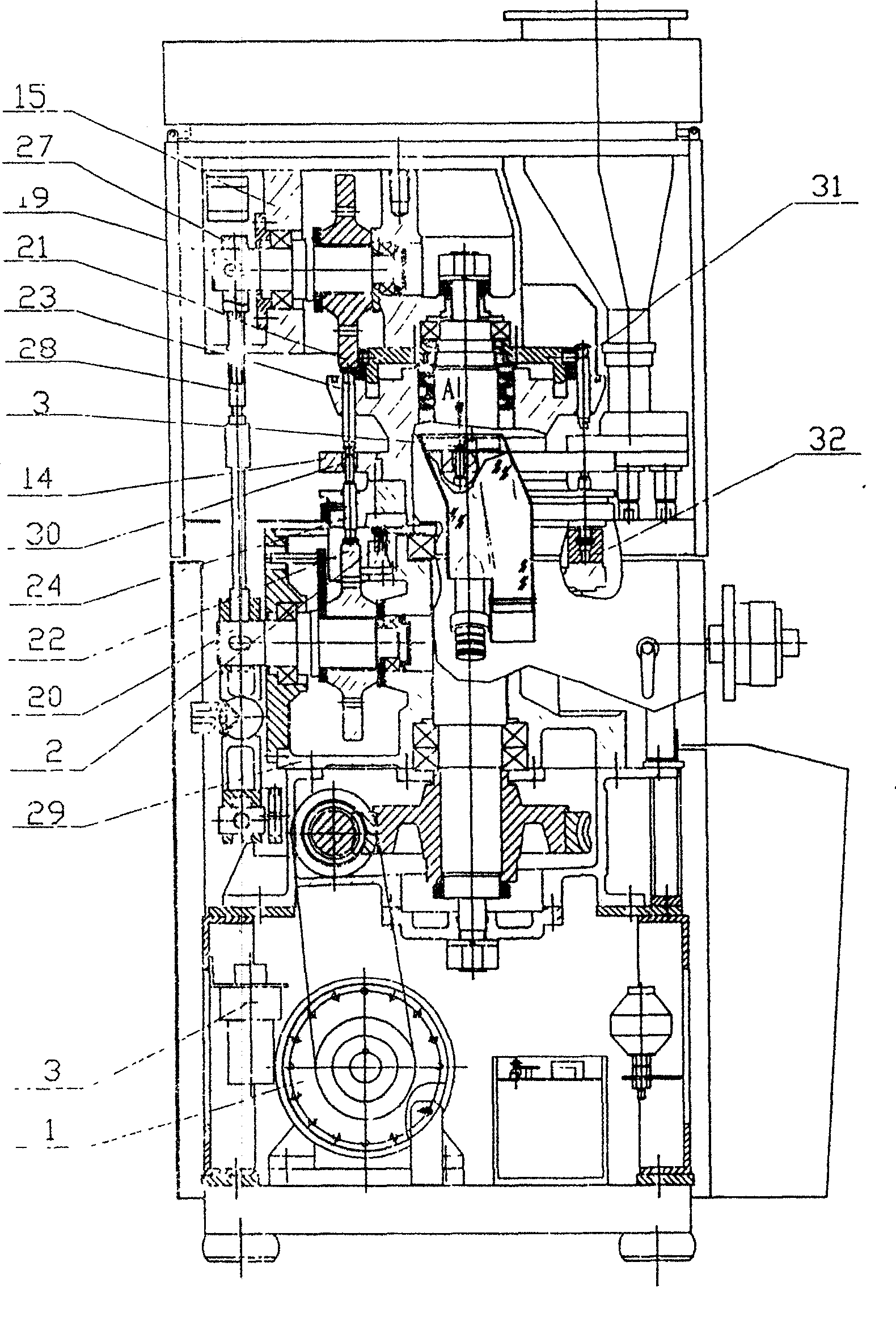

[0041] Such as figure 1 , the frame 29 and the support block 15 of the tablet press are respectively provided with upper and lower eccentric shafts 19 and 20; , The cooperation of the lower guide rails 31 and 32 controls the relative reciprocating movement of the upper and lower punches 23 and 24 of each pair of dies, and the tablet is pressed into shape in the middle die 30 .

[0042] Such as figure 1 , 2 And 4, the single-chip rejection device of the high-speed rotary tablet press of this embodiment includes: a central control unit, a tablet weight detection mechanism, an advanced disc assembly 1 arranged on the main motor 17 of the tablet press, The production tray combination 2 and the pneumatic reject system 3 under the turntable.

[0043] The central control unit is a programmable logic controller PLC.

[0044] The sheet weight detection mechanism includes: a pressure sensor 27 and a connecting rod 28 arranged at one end of the upper eccentric shaft 19 and connected ...

Embodiment 2

[0059] On the basis of Embodiment 1, the advanced disk combination 1 of this embodiment can also have the following deformations:

[0060] The leading disc assembly 1 includes: a compensation sensor 7 and a compensation code disc 6 arranged on the output shaft of the main motor 17 .

[0061] The compensation code wheel 6 is provided with 50 counting holes evenly distributed on a circumference. The number of punches and dies of the tablet press is 55.

[0062] The compensation sensor 7 includes an optical signal transmitter fixedly arranged on one side of the compensation code wheel 6 and an optical signal receiver fixedly arranged on the other side of the compensation code wheel 6 and connected to the central control unit. The straight line where the optical signal transmitter and the optical signal receiver are located is perpendicular to the circumference where the counting holes are located, so as to generate the compensation pulse signal when the compensation code wheel 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com