Optically pumped semiconductor device

A semiconductor and optical pumping technology, applied in semiconductor laser excitation devices, semiconductor lasers, excitation methods/devices, etc., can solve the problems of reduced pumping efficiency, achieve low technical costs, eliminate consistency, and high pumping efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

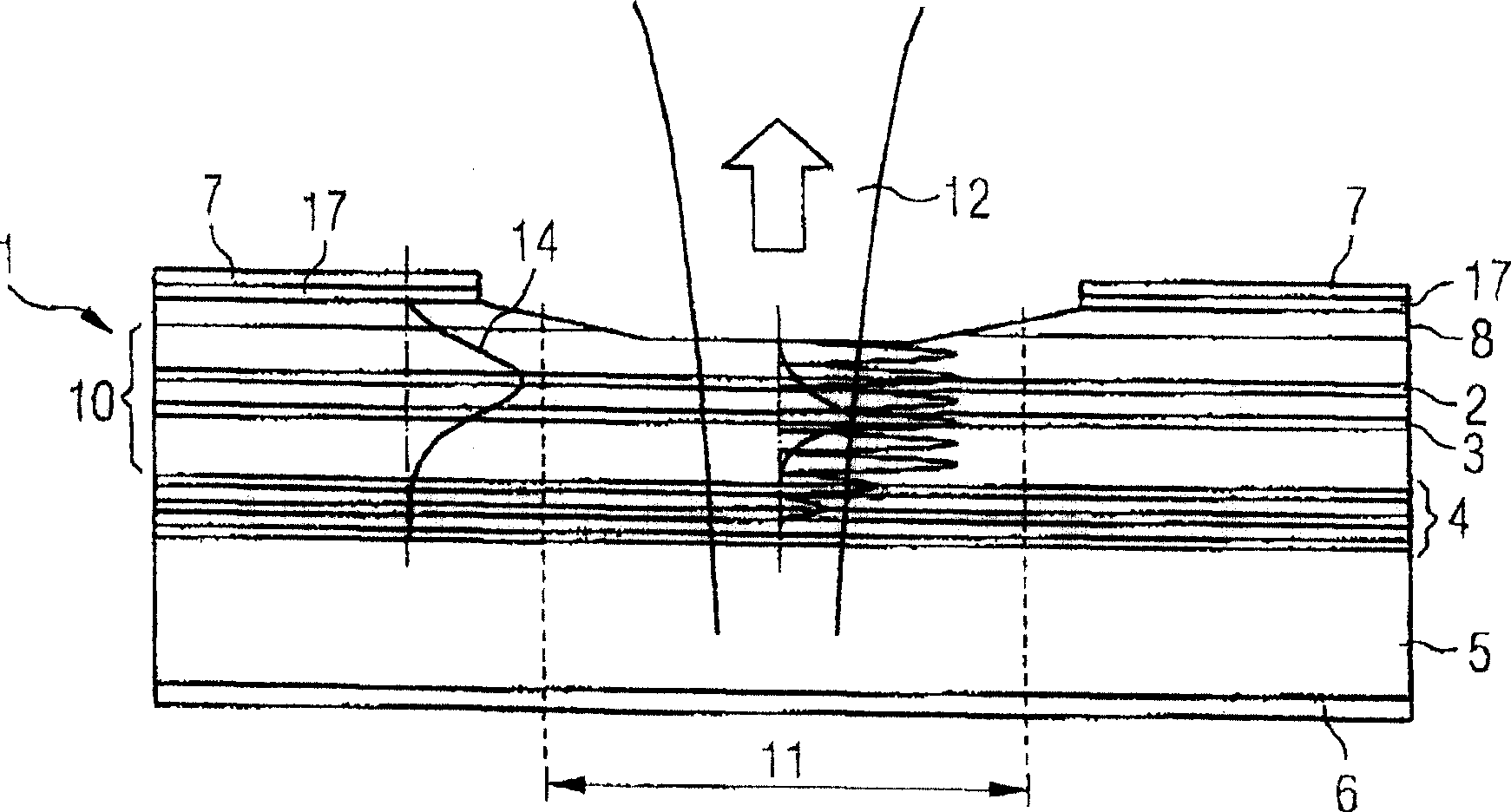

[0037] Identical or identically acting elements are provided with the same reference symbols in these figures.

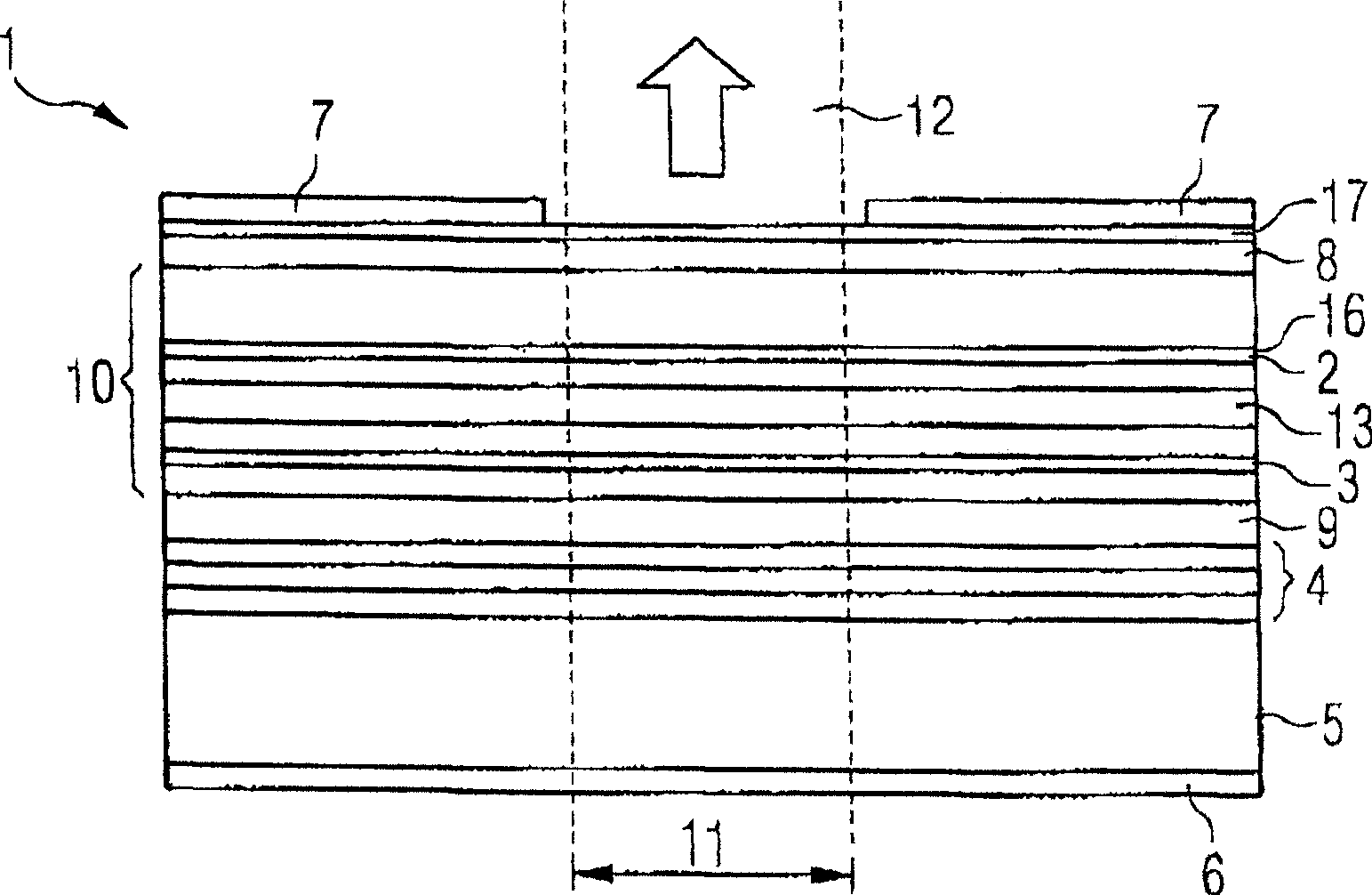

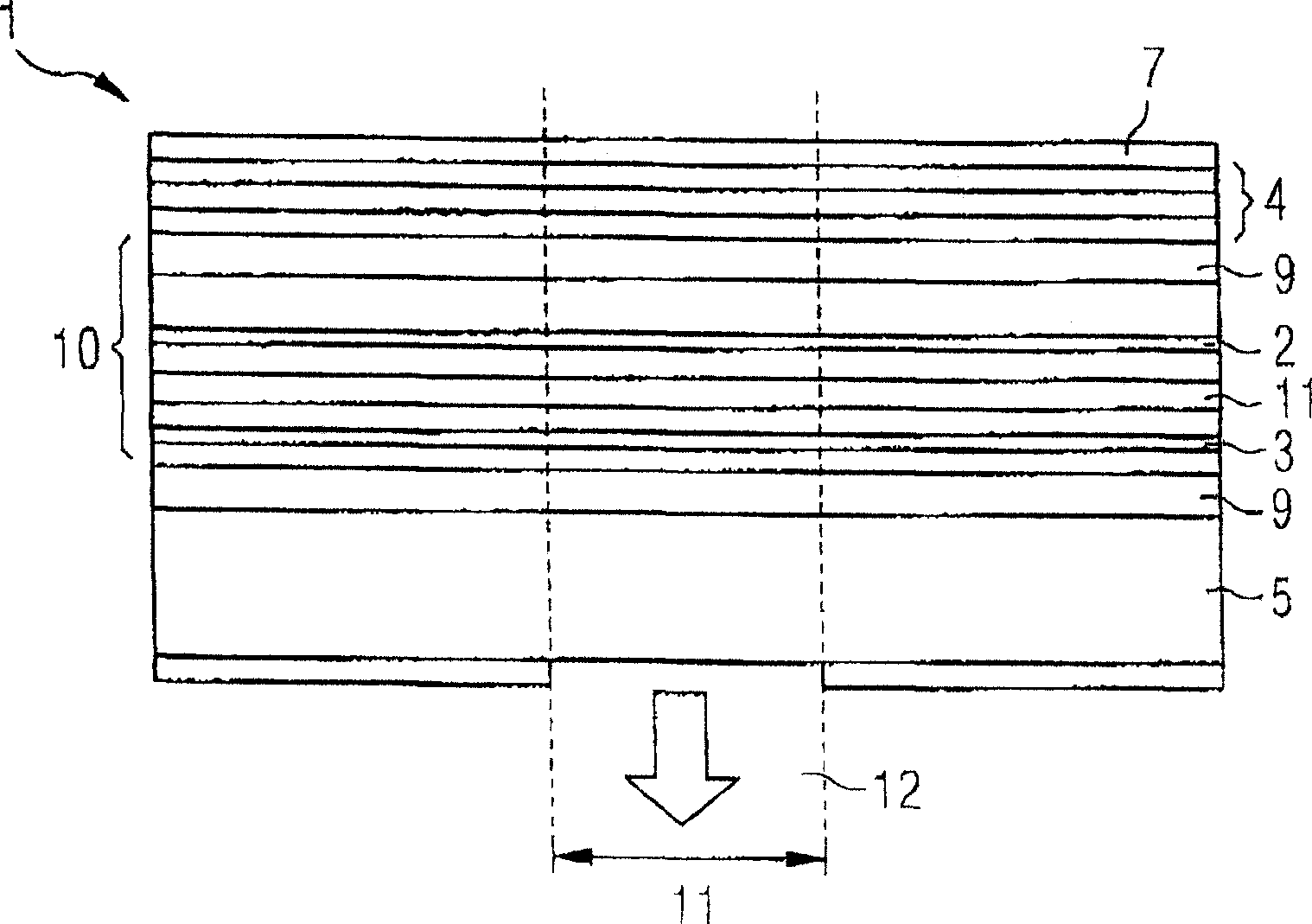

[0038] figure 1 The embodiment of an optically pumped semiconductor device according to the invention shown in has a semiconductor body 1 comprising an active pumping layer 2 and a An active vertical emission layer 3, wherein the pumping layer 2 and the vertical emission layer 3 are arranged parallel to each other.

[0039] Furthermore, the pump layer 2 and the vertical emission layer 3 are formed in a waveguide 10 , to which a first cover layer 8 and a second cover layer 9 adjoin oppositely.

[0040] Arranged behind the waveguide in the vertical direction are a Bragg reflector 4 and a substrate 5 which is provided with a contact metallization 6 on the side facing away from the semiconductor layers. Accordingly, a contact layer 17 and a second contact metallization 7 are applied to the first cover layer 8 on the opposite side of the semiconductor body, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com