Apparatus for micrifying fuel

A technology for fuel and oil treatment, which is applied to mixers, combustion methods, mechanical equipment, etc., and can solve problems such as poor treatment of heavy oil, poor micronization of fuel oil, and influence on flow rate and flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

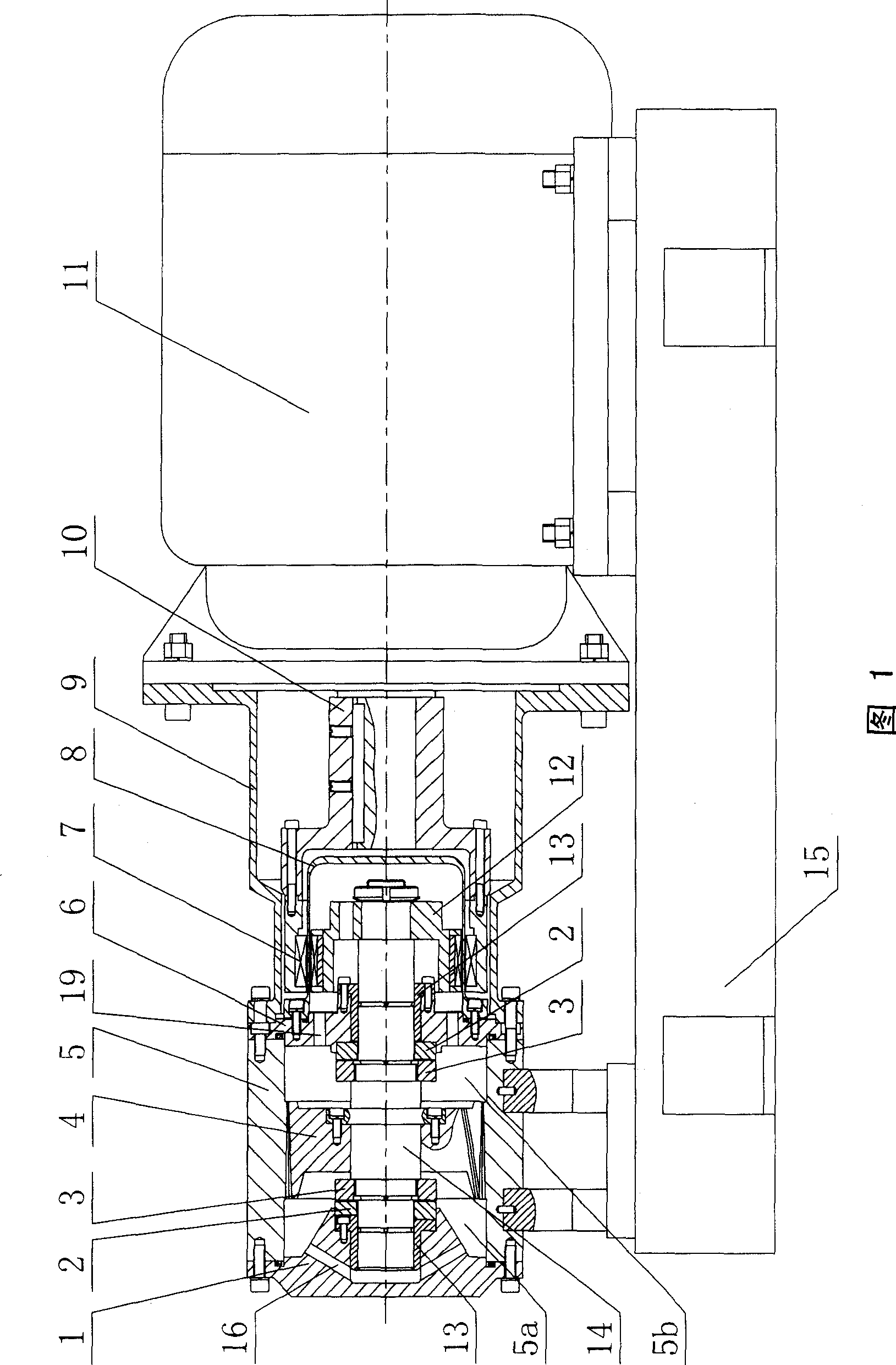

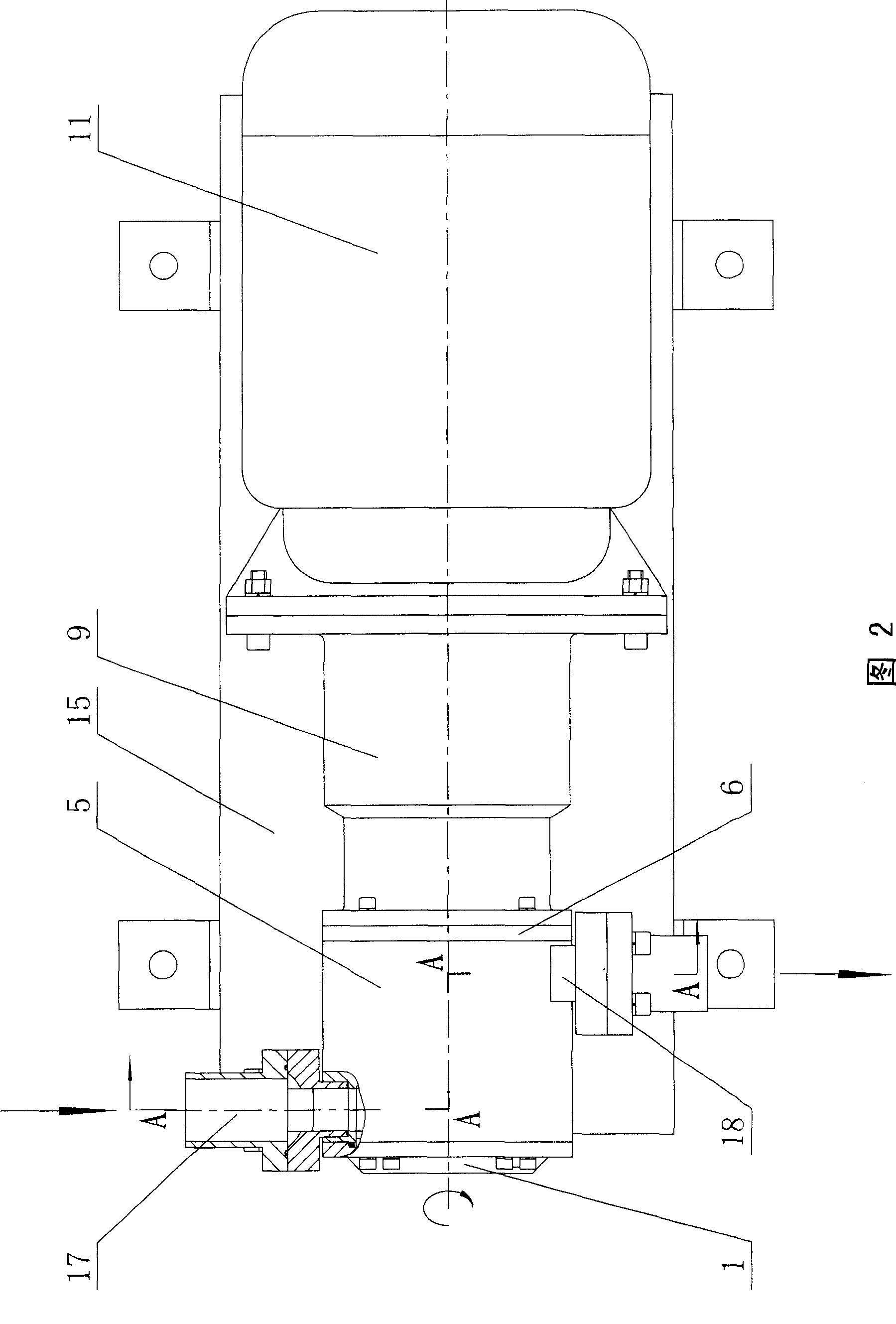

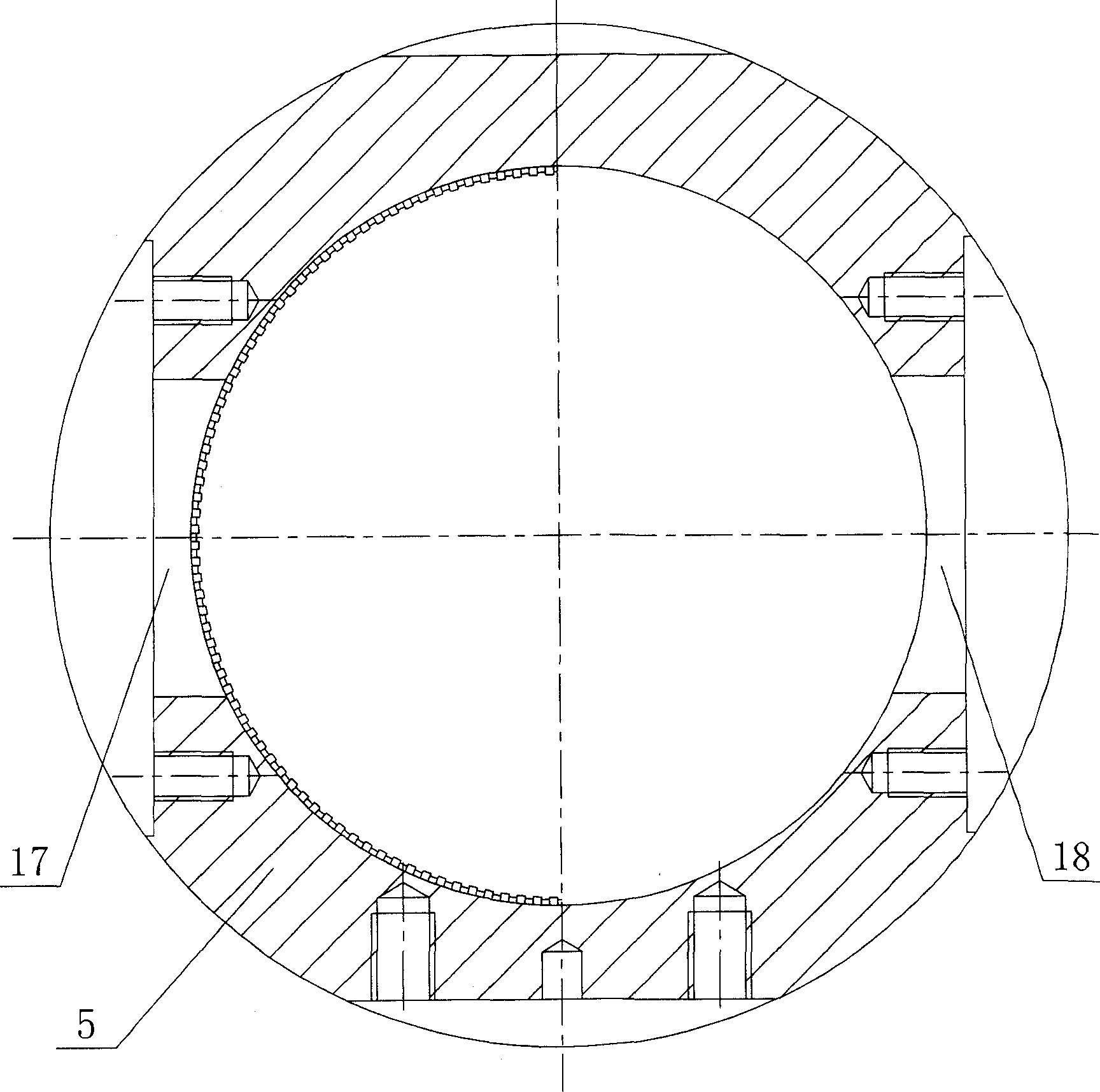

[0025] Figure 1, Figure 2, image 3 , Figure 4, Figure 5, Figure 6 , Figure 7 As shown, the present invention includes a motor 11, a base 15, a coupling, and an oil treatment device, the coupling connects the motor 11 and the oil treatment device, and the oil treatment device includes a front end cover 1, two second One friction ring 2, two second friction rings 3, rotor 4, stator 5, rear end cover 6, protective cover 9, two sliding bearings 13, stepped shaft 14, oil inlet 17, oil outlet 18, the The stator 5 is a housing with a cylindrical inner cavity, the stator 5 is fixedly connected to the base 15, the front end cover 1 and the rear end cover 6 are respectively fixedly connected to the two ends of the stator 5 to To achieve sealing, the two ends of the protective cover 9 are respectively connected with the motor 11 and the stator 5 and are covered on the outside of the coupling to protect the coupling and increase the safety of operation. The rotor 4 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com