Suspension holder construction method

A construction method and suspension frame technology, which is applied in the direction of construction and building construction, can solve the problems of difficulty in disassembly, high cost, easy instability of formwork frames and scaffolding, etc., so as to achieve a stable structure system, save construction costs, and be simple and convenient. The effect of the construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

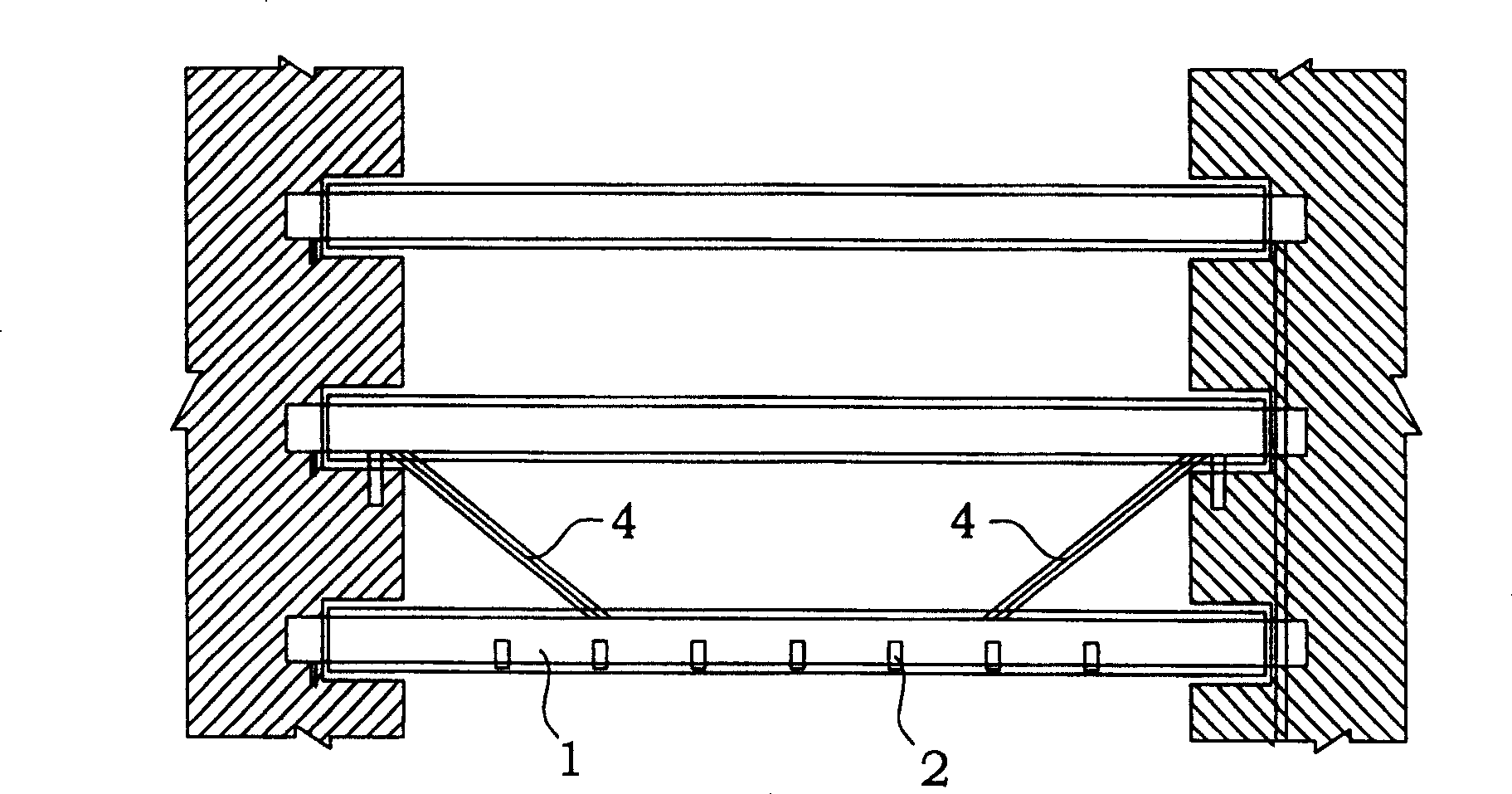

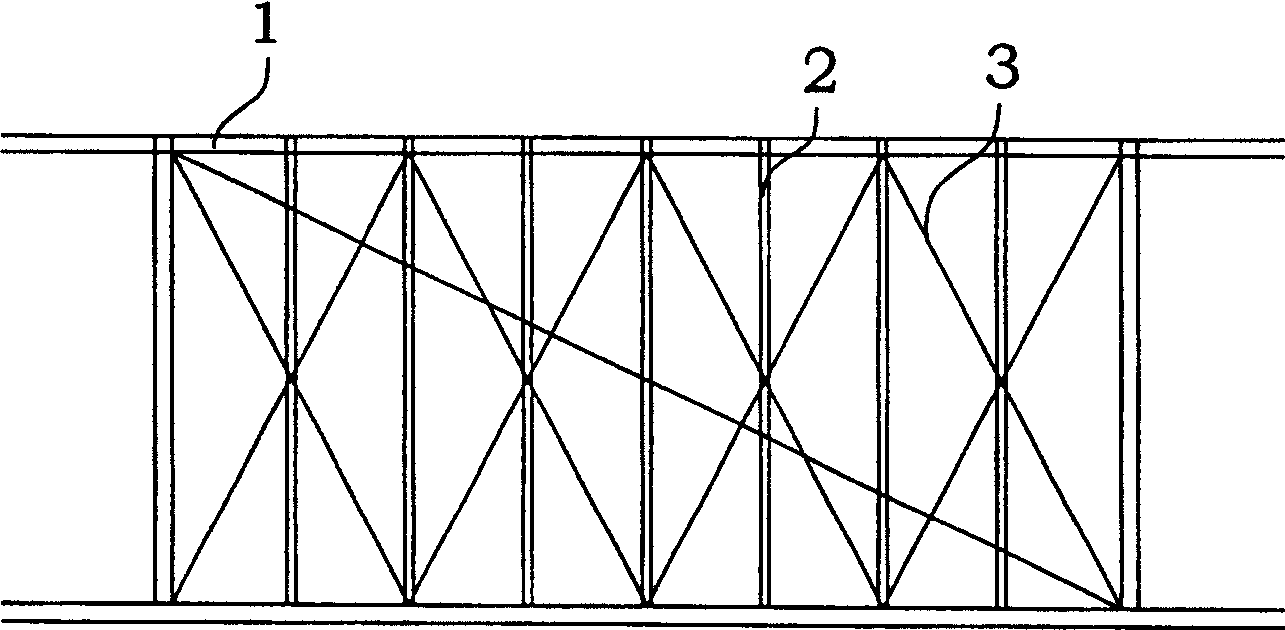

[0025] Below in conjunction with specific construction process, the present invention is described in detail (taking the construction of air corridors on the 21st, 22nd and 23rd floors as an example).

[0026] 1. The production of inner-wrapped I-beams: generally welded with 10 mm thick A3 steel plates (partial webs can use 20 mm steel plates due to large concentrated loads); some accessories are prepared in advance to minimize high-altitude operations.

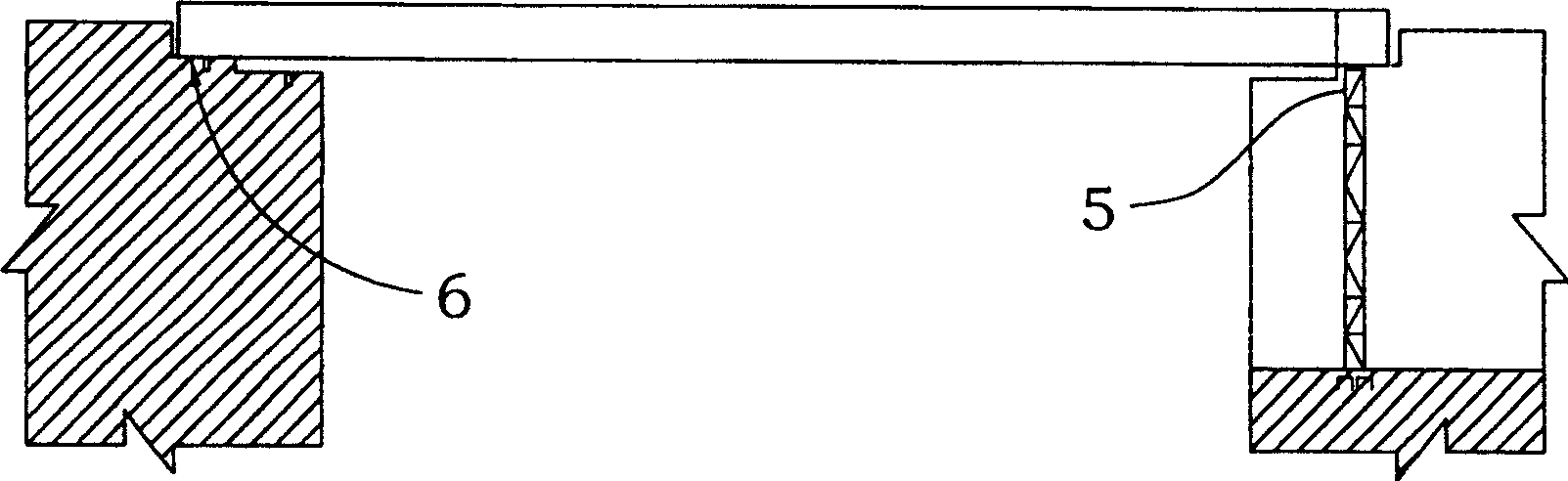

[0027] 2. Hoisting of inner-wrapped I-beam (see details image 3 ): The poured floor concrete on the 20th, 21st, and 22nd floors should be pre-embedded for the steel plate 6 and the lattice column 5 used to place the inner-wrapped I-beam 1. When placing the lattice column, attention should be paid to the axis, Elevation and verticality; the 21st floor I-beam is hoisted when the 21st floor concrete of the first main building is poured and the 21st floor formwork of the second main building is completed, and one end is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com