Lock core device for anti-pry and anti-universal key

A master key and lock cylinder technology, used in locks with turning keys, construction locks, cylinder locks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

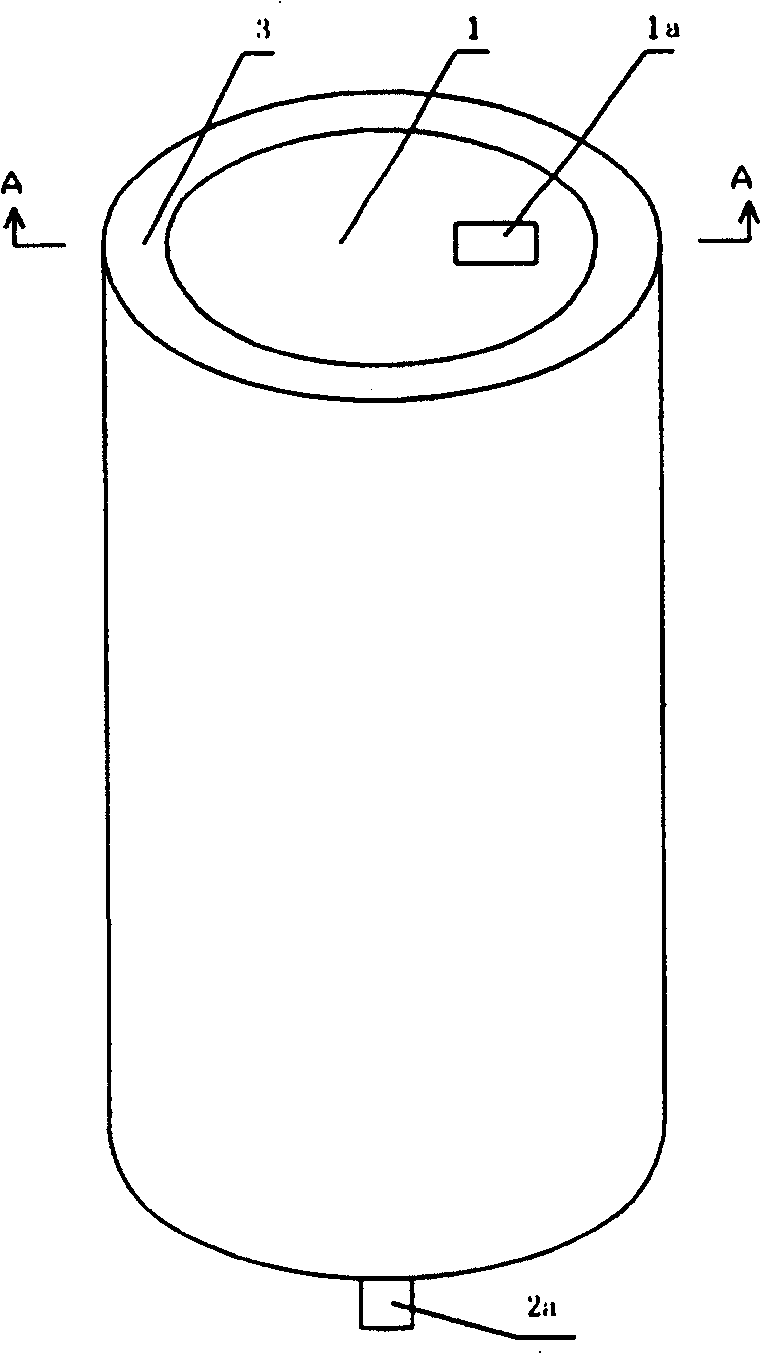

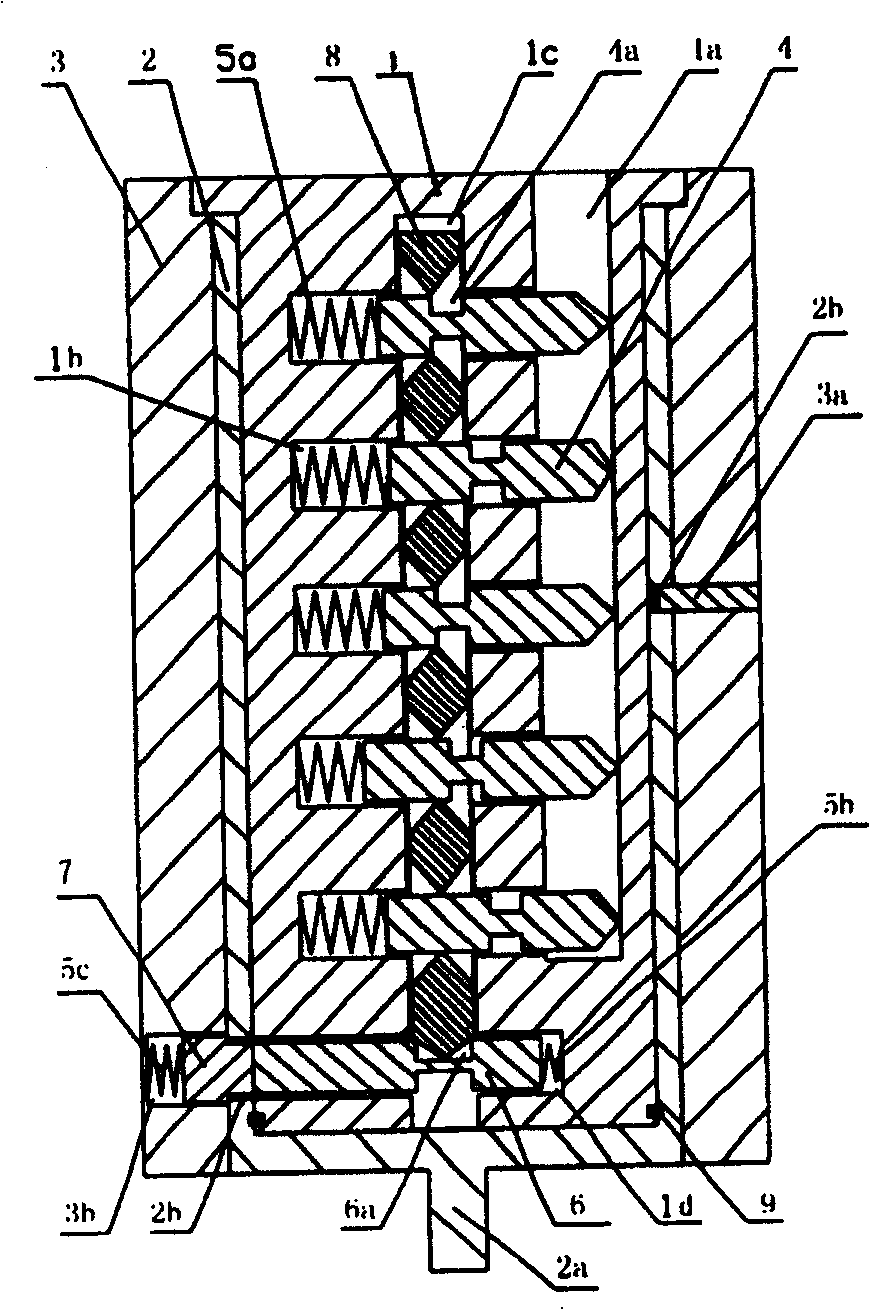

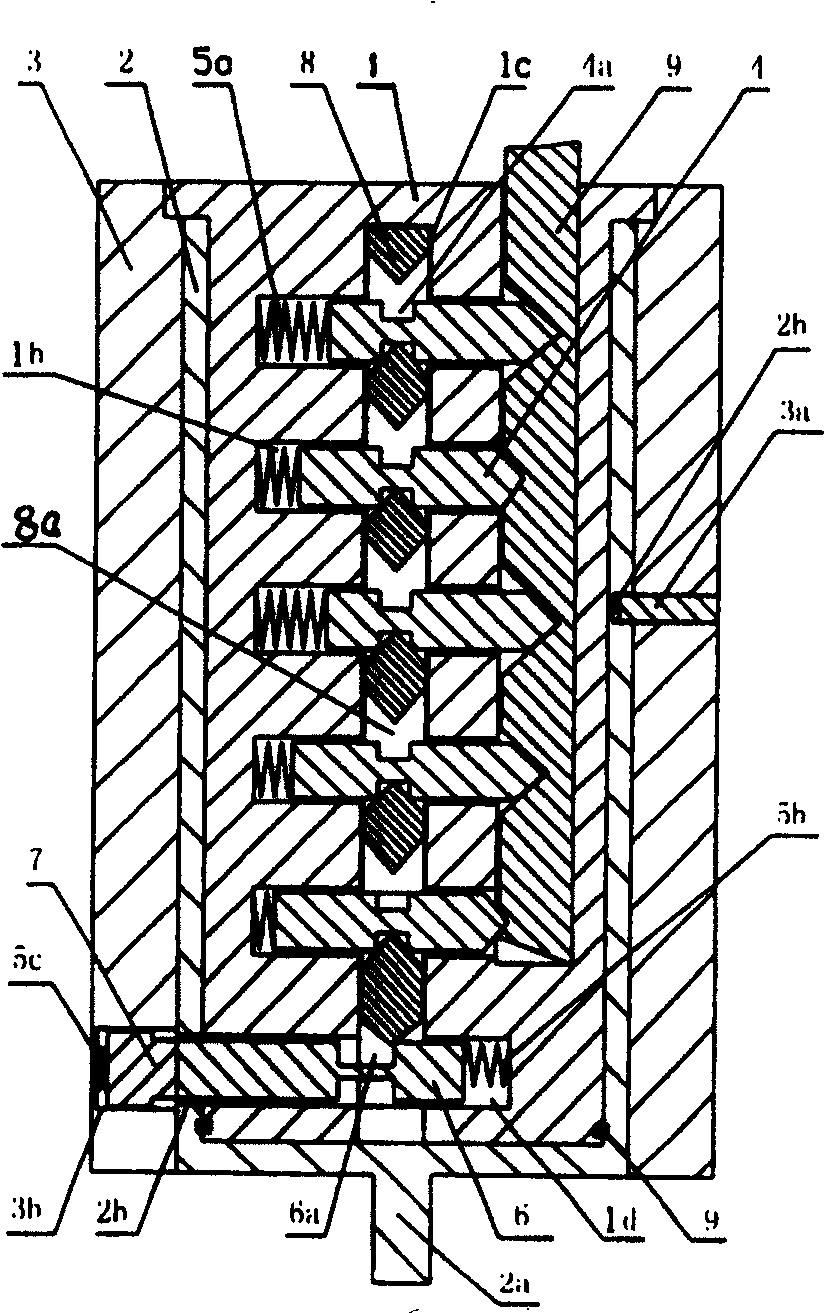

[0038] Embodiment 1: with reference to attached figure 1 , 2 , 3, 4, 5, 6, 7. It can be seen from the figure that the inner lock cylinder 1 is rotatably fitted in the outer lock cylinder 2, and the outer lock cylinder 2 is fitted in the tubular lock cylinder fixing seat 3; the upper end of the inner lock cylinder 1 is provided with an outer flange, assembled Finally, the outer flange covers the outer lock core 2; the bottom surface of the outer lock core is provided with a shift fork 2a, and the dead bolt can be moved to unlock by rotating the shift fork 2a. The lower ends of the inner lock core 1 and the outer lock core 2 are nested together by the elastic collar 9; a section of horizontal groove 2b is provided along the outer circumferential surface of the outer lock core 2, and the side wall of the lock core fixing base 3 is correspondingly fixed. There is a limit pin 3a, and the inner end of the limit pin 3a extends into the horizontal groove 2b to limit the rotation ang...

Embodiment 2

[0043] Embodiment 2: with reference to attached Figure 8 , 9 , 10, 11, 12, 13, 14, 15, 16. The difference between this embodiment and Embodiment 1 is that the inner lock cylinder 1 is provided with a rectangular blade groove 1e, and each blade groove 1e is respectively provided with two generally L-shaped blades 41, and the two blades 41 are placed opposite to the blade groove 1e. There is a distance 41b between the front end convex parts of the blades and the opposing surfaces of the notch parts at the rear ends. Wedge-shaped grooves 41a are respectively provided at specific positions on the lower parts of the notch parts of the two blades 41. According to the wedge-shaped concave parts of each blade, The different positions of the groove 41a form different password combinations. Return springs 5a are respectively arranged between the rear end surfaces of the two blades 41 and the bottom surface of the blade groove 1e, and each blade can move radially. The movable pin slot...

Embodiment 3

[0045] Embodiment 3: with reference to attached Figure 17 , 18 , 19, 20, 21, 22, 23, 24. The difference between this embodiment and Embodiment 2 is that a plurality of annular blade grooves 1f are arranged on the peripheral surface of the inner lock cylinder 1, and two arc-shaped blades 42 are respectively arranged in each blade groove 1f. The sum of the lengths of 42 is less than the perimeter of the blade groove 1f, the two blades 42 can slide towards each other along the blade groove, the two blades 42 are relatively placed on both sides of the blade groove 1f, and the specific positions of the opposite surfaces of the two blades 42 are respectively provided with The wedge-shaped groove 42a and the return spring 5a are supported between the rear end surfaces of the two blades 42 . The inner lock core 1 at the bottom of the blade groove 1f is fixed with a limiting convex portion 1g, and the inner side of the front end surface of the blade 42 is correspondingly provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com