Fully-mechanized mining working face smooth trough advancing reinforcement support process and hydraulic support therefor

A fully-mechanized mining face and hydraulic support technology, which is applied to pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of high workload and labor intensity of workers' support, unsafe and low work efficiency of returning to the top of the column , to achieve the effect of reducing workload and labor intensity, increasing support height and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

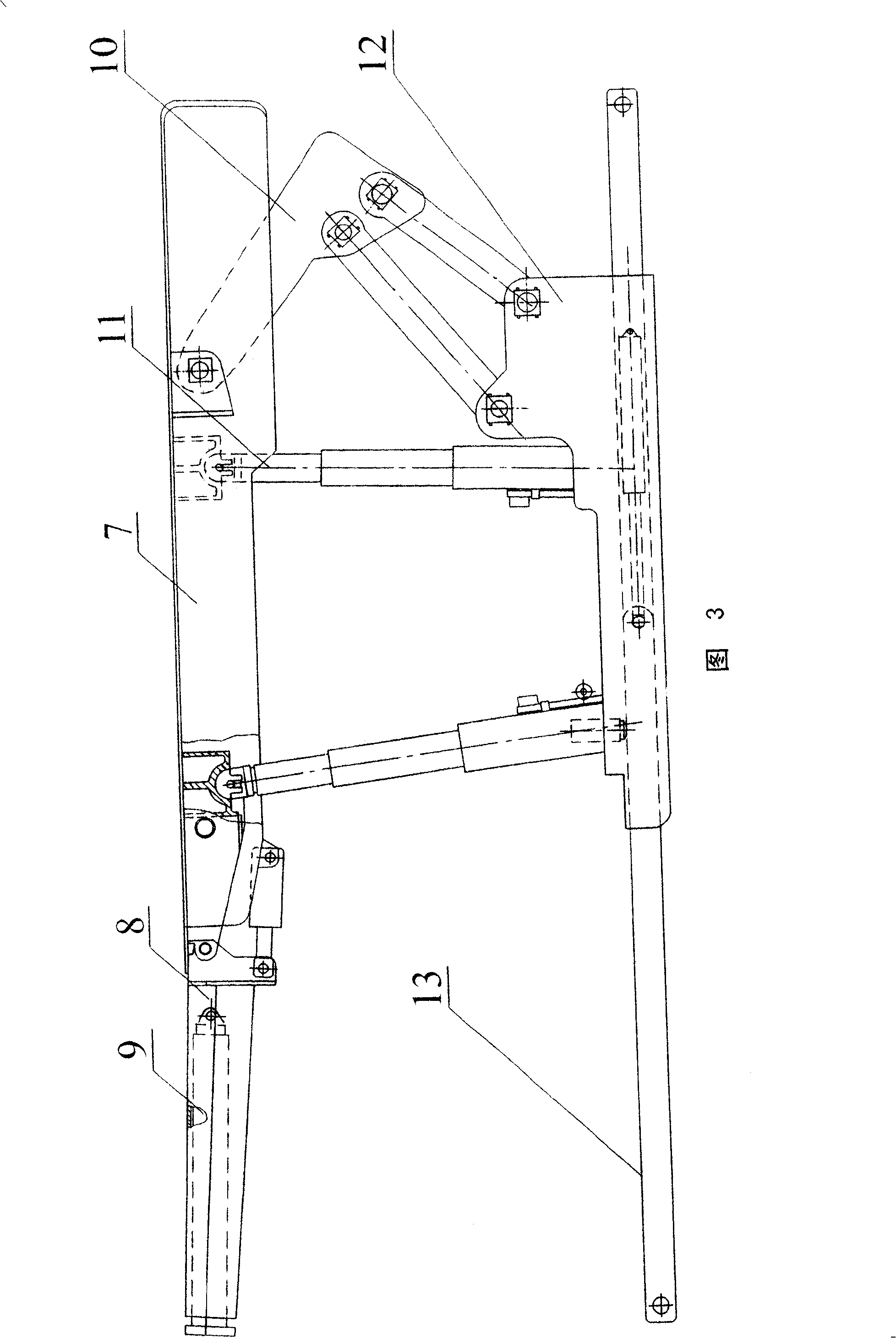

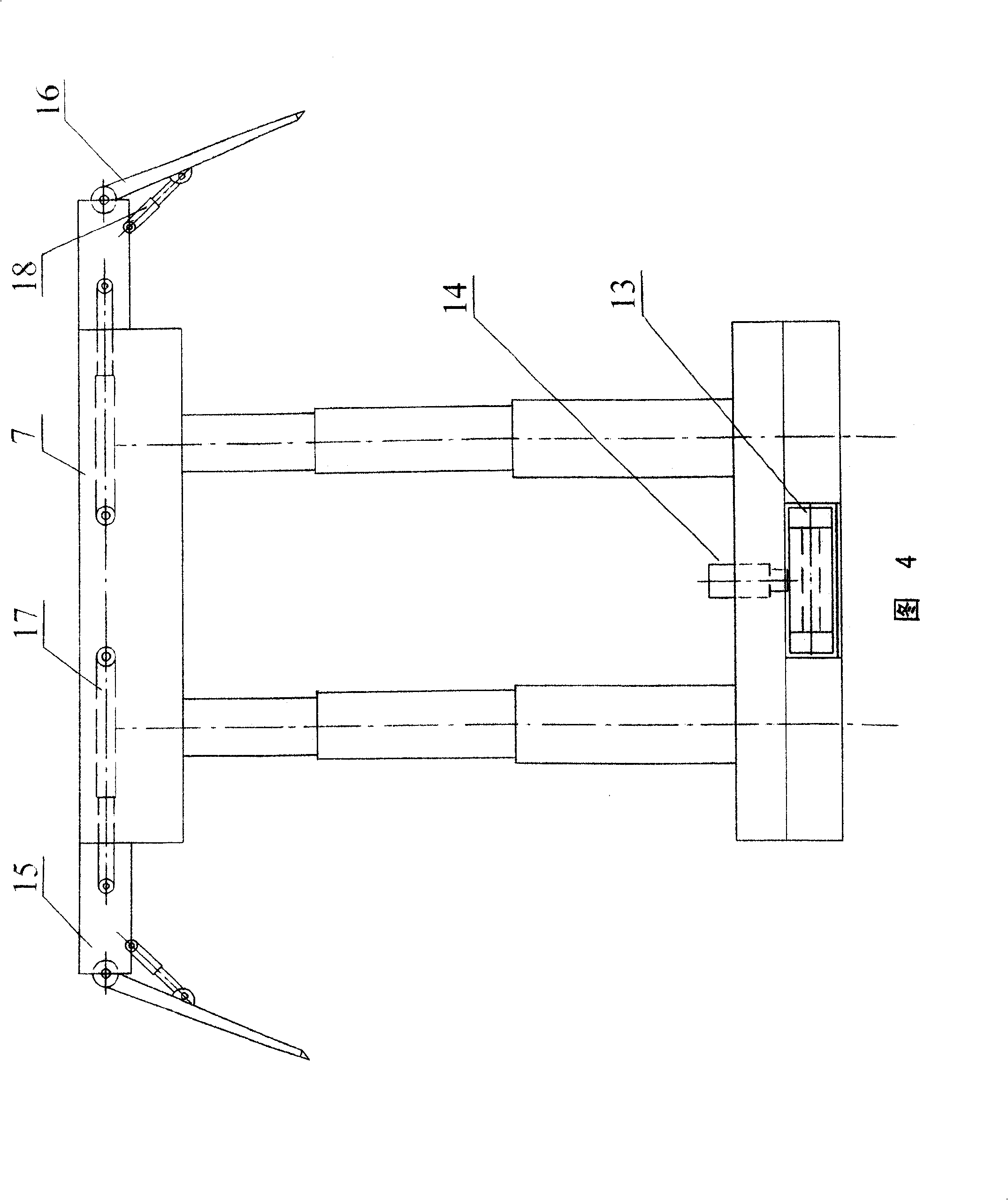

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

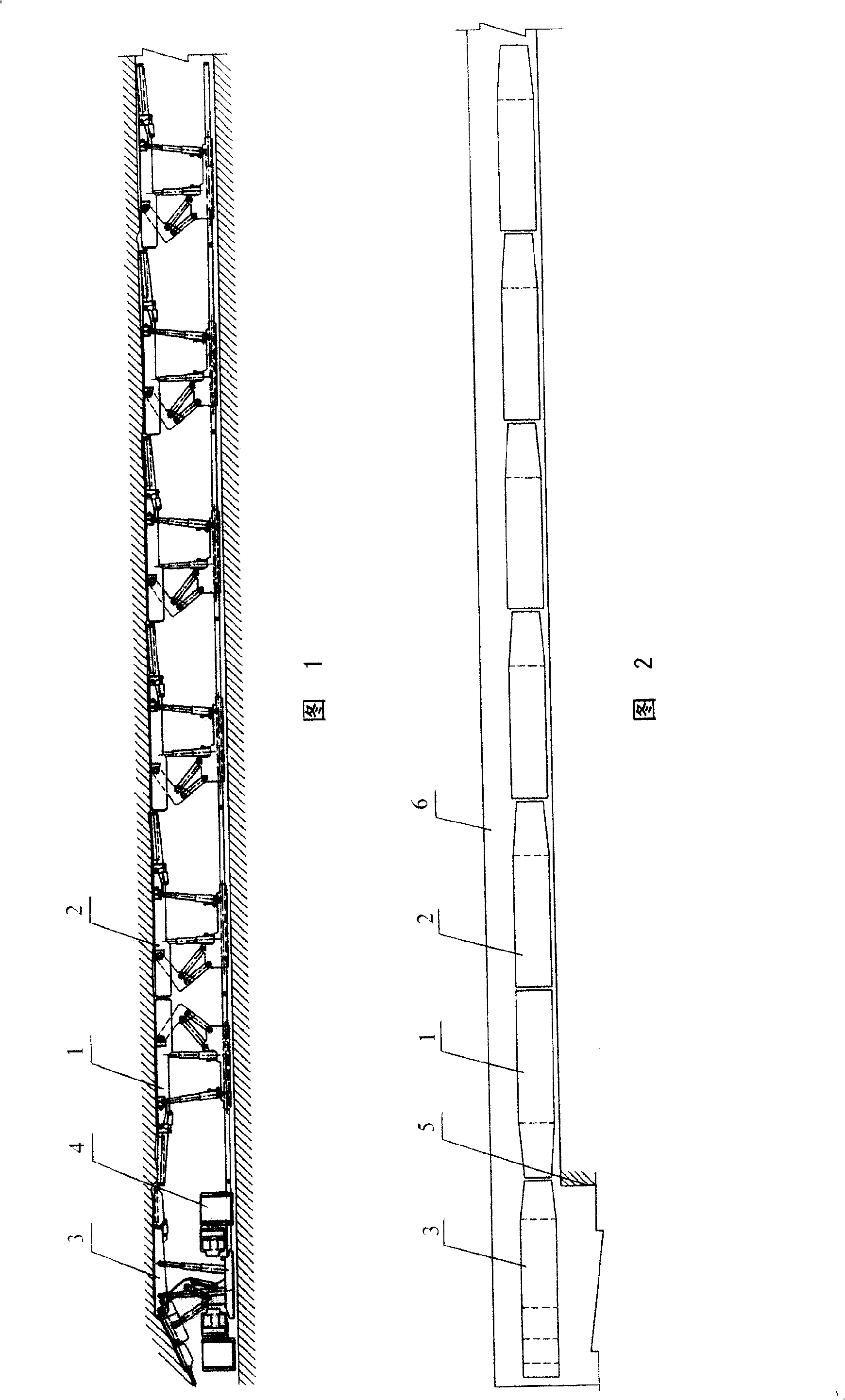

[0020] Figures 1 and 2 show the arrangement of the advance reinforced support hydraulic supports 1 and 2 and the end hydraulic supports 3 in the track groove 6 of the fully mechanized top coal caving face of the present invention. Take this as an example to illustrate the specific method of this technology in advance strengthening the support in the track channel 6 of the fully mechanized mining face. The specific method is as follows:

[0021] ① Arrange a group of terminal hydraulic supports 3, or one frame, at the end of track slot 6; in track slot 6, lay multiple groups of advance reinforced support hydraulic supports 1, 2. There can be 4 to 11 groups, preferably six groups; among them, the first group of advanced reinforced support hydraulic supports 1 is arranged in an inverted manner, facing and connected to the end hydraulic supports 3, and the remaining advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com