Wood plastic template in use for architecture

A technology for wood-plastic formwork and construction. It is applied in the direction of construction, building structure, formwork/formwork components, etc. It can solve the problems of time-consuming and labor-intensive assembly and disassembly, unimaginable consequences, waste of wood resources, etc., so as to facilitate construction and save energy. Materials and labor costs, the effect of saving wood and steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

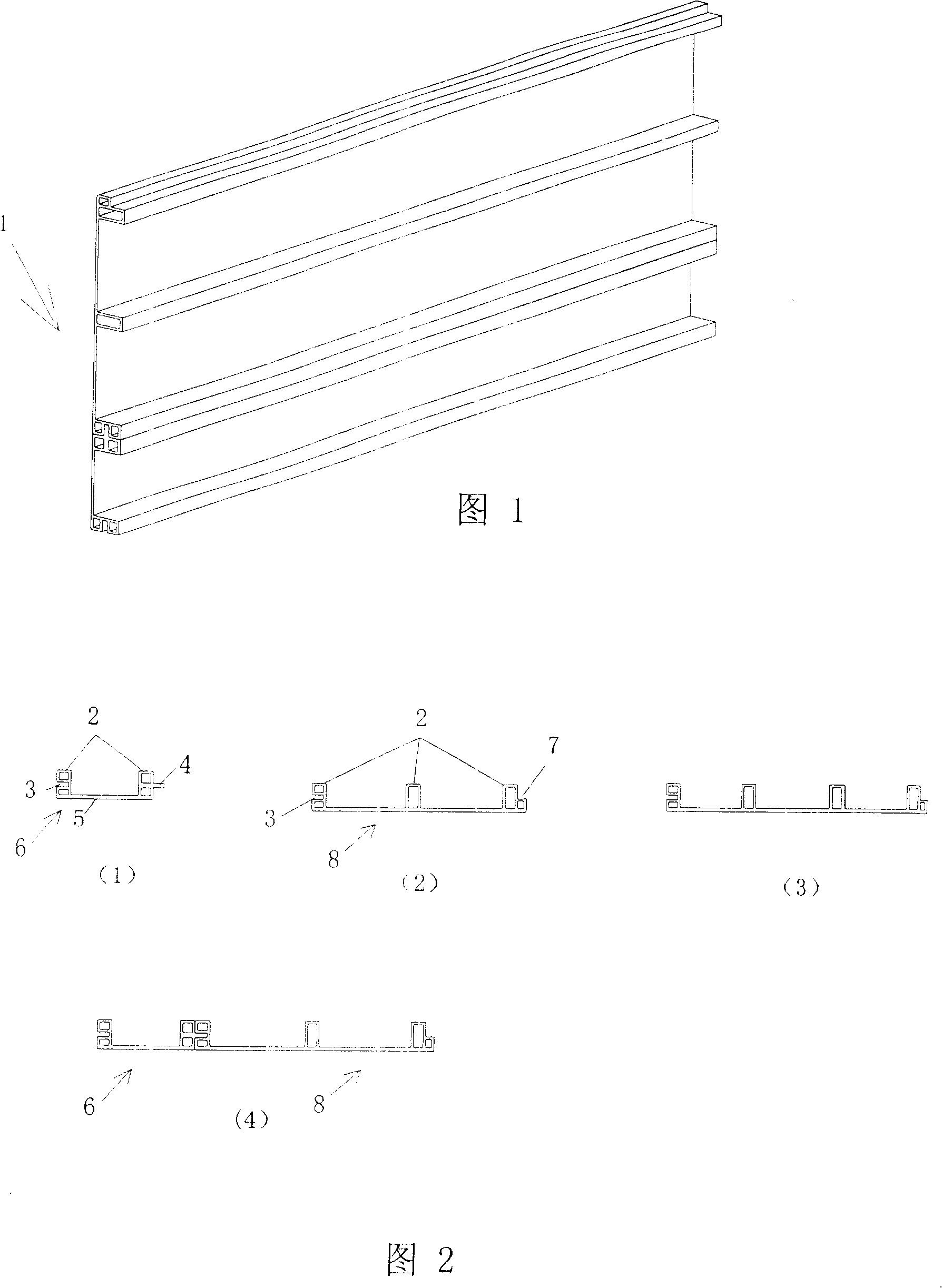

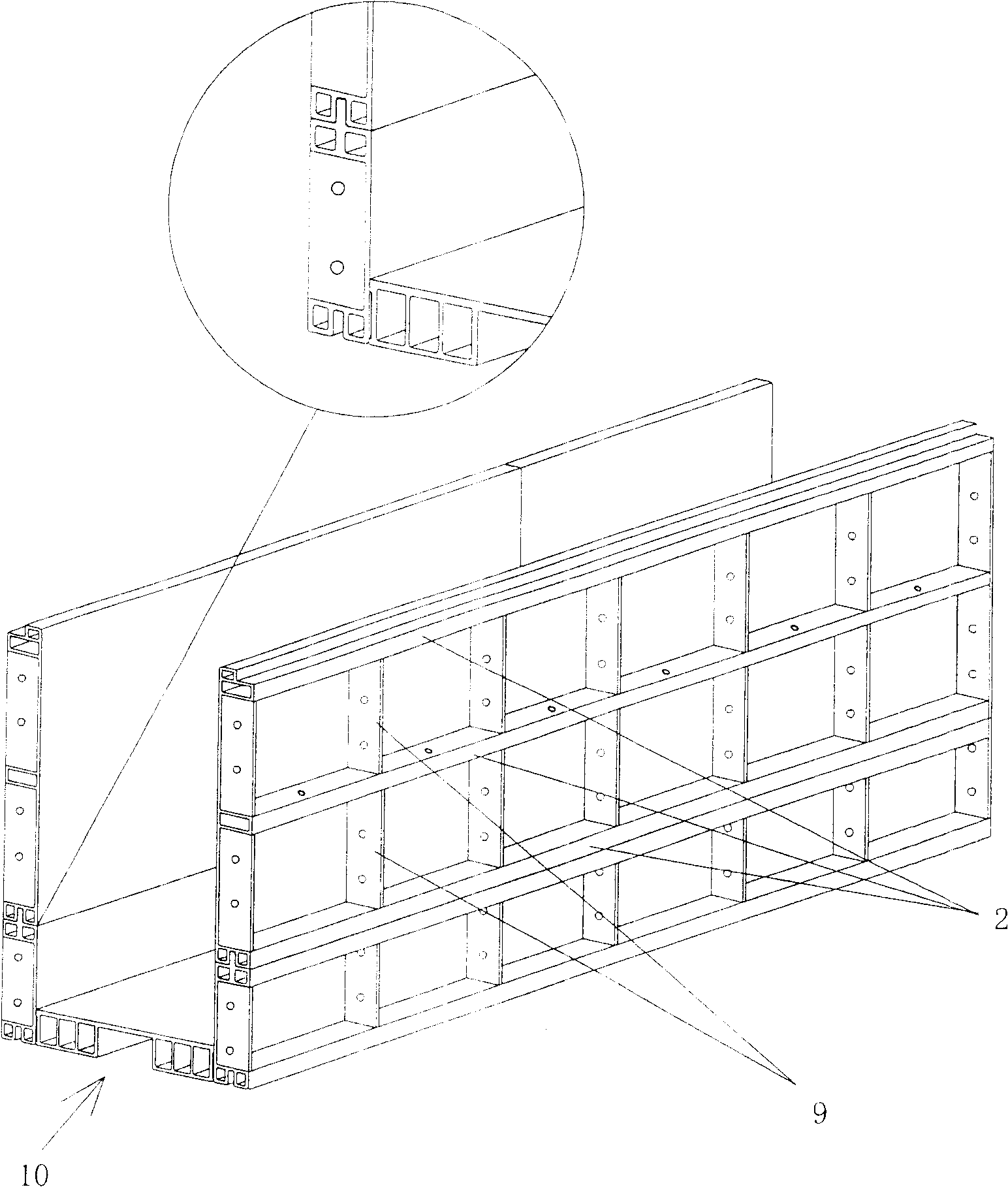

[0041] See Figure 1, Figure 2, image 3 , Figure 4, Figure 6, Figure 7, Figure 8 , Figure 9 , Figure 10 , Figure 11 Shown: a kind of wood-plastic formwork for building, it comprises beam side formwork 1, beam bottom formwork 10, beam column formwork 21, large formwork 22, described beam side formwork 1, beam bottom formwork 10, beam column formwork 21 1. The large formwork 22 is made of wood-plastic profiles, and the wood-plastic profiles include a panel and a main back panel, and the panel and the main back panel are integrally formed by wood-plastic extrusion.

[0042] The upper side of the beam side wood plastic profile 8 of the beam side formwork 1 has a lap groove 7, and the beam side auxiliary back panel 9 is connected at a transverse interval between the main back panels 2 of the beam side wood plastic profile 8 .

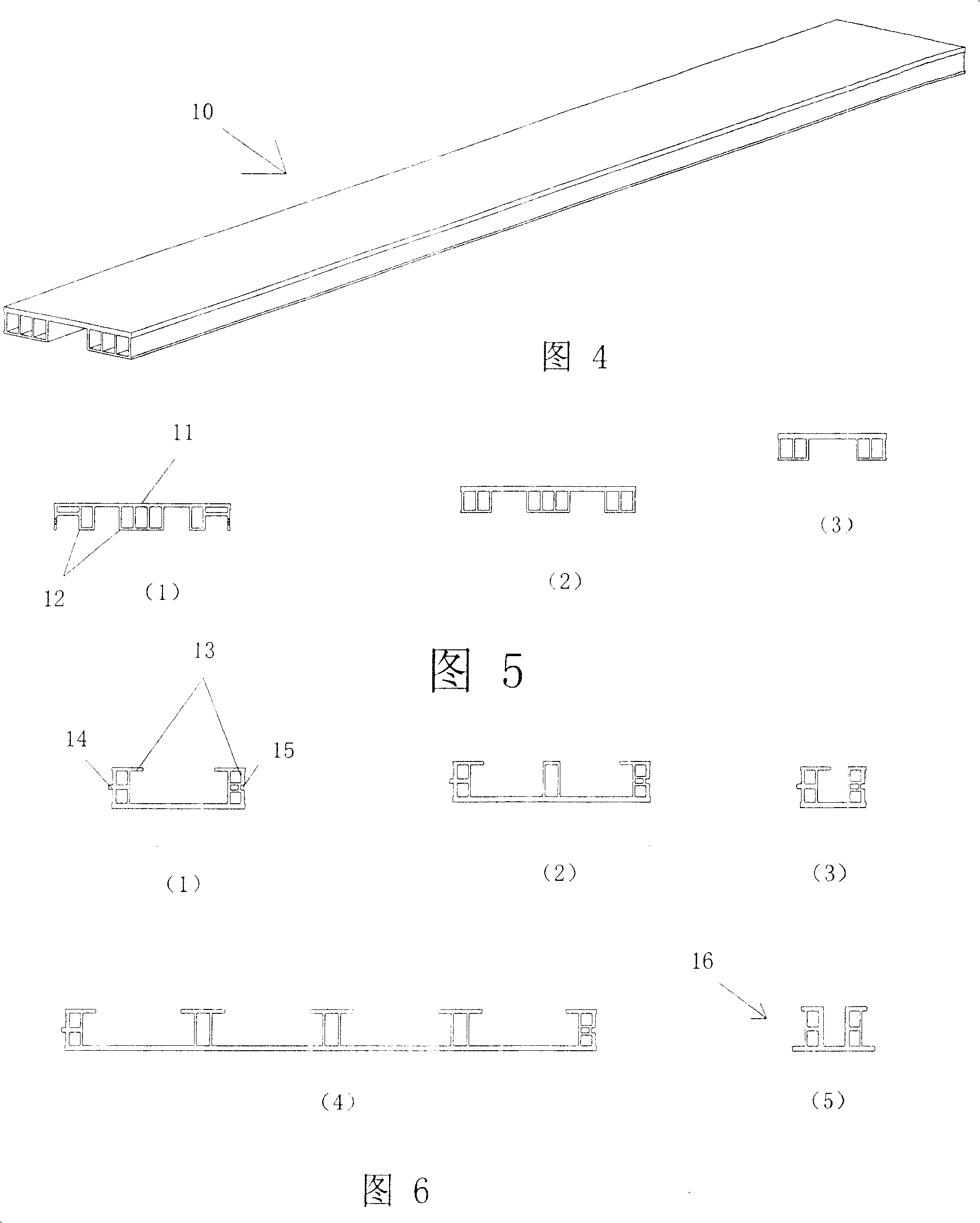

[0043] Beam bottom template 10 is made of panel 11 and main back 12 (seeing Fig. 4, shown in Fig. 5).

[0044] If the beam side formwork needs to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com