Production technology of laser locating antifalse cigarette box

A laser positioning and production process technology, applied in printing, flexible covering, packaging and other directions, can solve the problems of weak laser anti-counterfeiting effect, low segmentation accuracy, easy deformation of paper, etc., to improve anti-counterfeiting performance, not easy to be Forgery, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

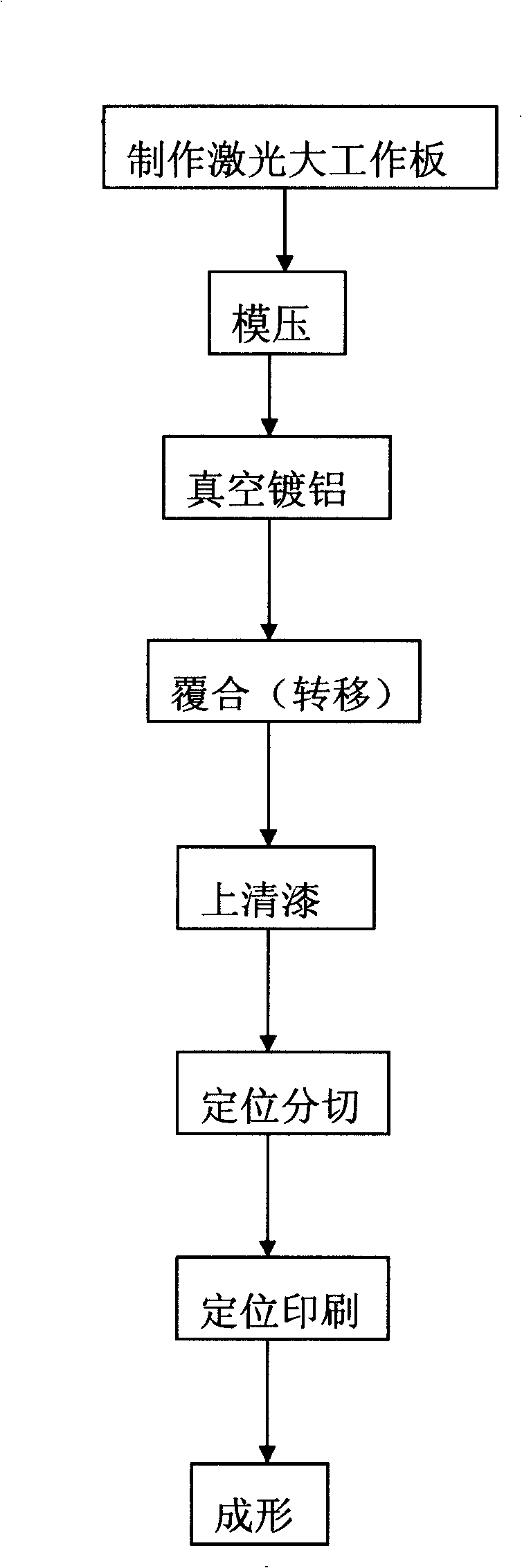

[0016] Embodiment: a kind of laser positioning anti-counterfeiting cigarette case production process, such as figure 1 As shown, it consists of the following processes: A. Make a large laser work board, make the design drawing into a laser master board, then turn the laser master board into a work board, and then assemble multiple work boards into a large work board; The laser mother board is made of glass, and the laser working board is made of metal. B. Molding: use a soft press or a hard press to emboss the pattern on the large laser working plate on the polypropylene (OPP) film or polyester (PET) film; C. Vacuum aluminum plating, the vacuum aluminum plating machine Spraying aluminum on polypropylene (OPP) film or polyester (PET) film; D, Lamination, laminating the sprayed laser film on white board paper with glue; A number of technologies are organically combined, and the transferable holographic plastic film is made first, and then transferred to the white board; E, varn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com