Apparatus and method for base plate conglutination

A technology for bonding devices and substrates, which is applied in the directions of optics, instruments, electrical components, etc., and can solve the problems that the upper substrate 1a and the sealant 5 are not in good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

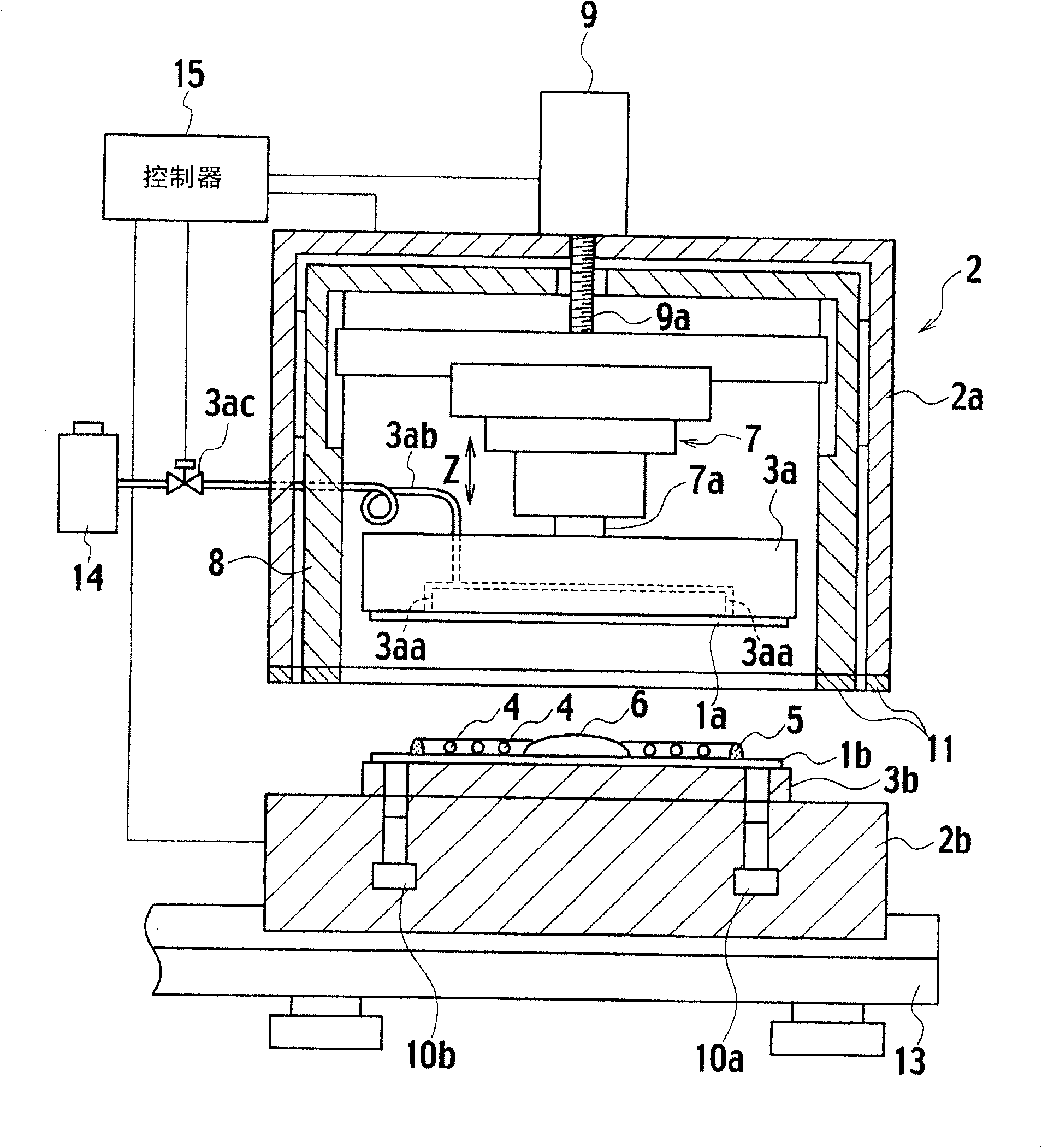

[0036] Refer to the following Figure 4 to Figure 9 An embodiment of the substrate bonding method and the substrate bonding apparatus of the present invention will be described in detail. Also, in Figure 4 to Figure 11 in, for with figure 1 The same structures as the conventional structure shown in FIG. 3 are assigned the same symbols and detailed description thereof will be omitted.

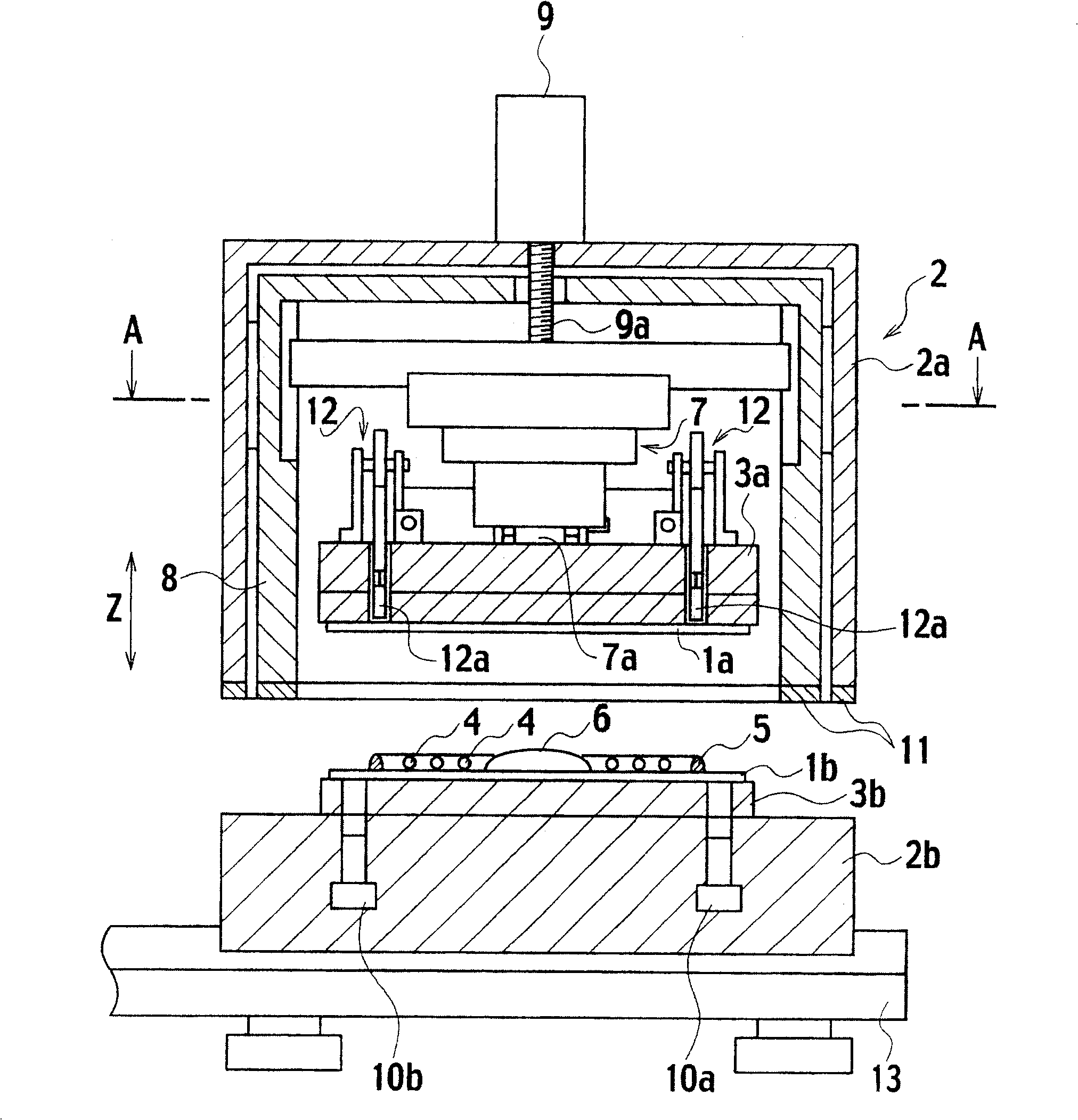

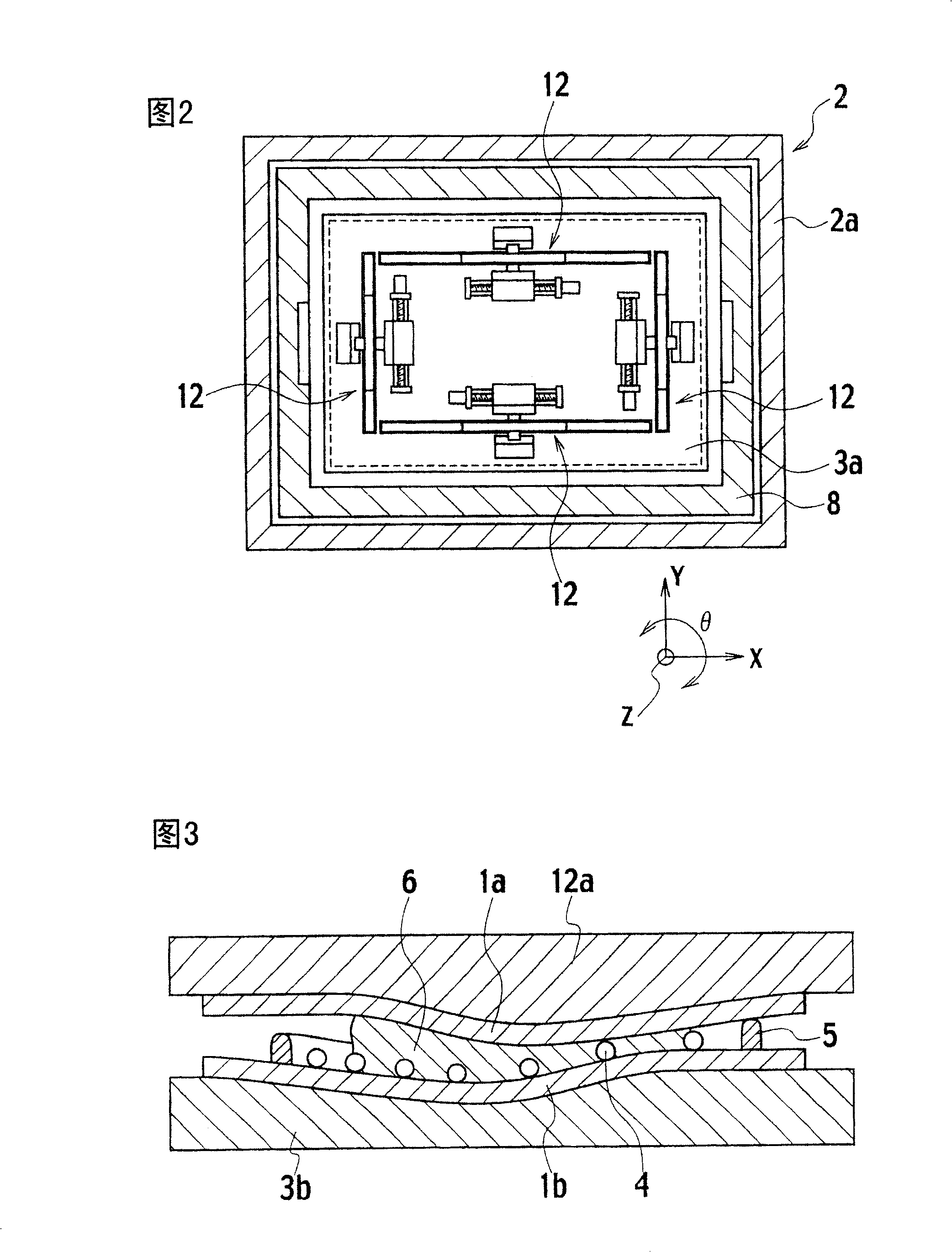

[0037] Figure 4 It is a configuration diagram showing the first embodiment of the substrate bonding apparatus of the present invention.

[0038] exist Figure 4 Among them, the substrates 1a, 1b made of thin glass constituting a pair of upper and lower rectangular shapes are in the chamber 2 composed of the upper and lower chambers 2a, 2b, and the upper substrate 1a is held on the lower surface of the upper chuck 3a by suction, etc. 1b is placed and held on top of the lower suction cup 3b.

[0039] The display surface of the lower substrate 1b is provided with a spacer 4 in advance, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com