Combined liqued resistance type digital hydraulic control technology

A digital hydraulic and combined technology, applied in the direction of mechanical equipment, circuit components, etc., can solve the problem that the structure is difficult to replace each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, provide a best embodiment of the present invention.

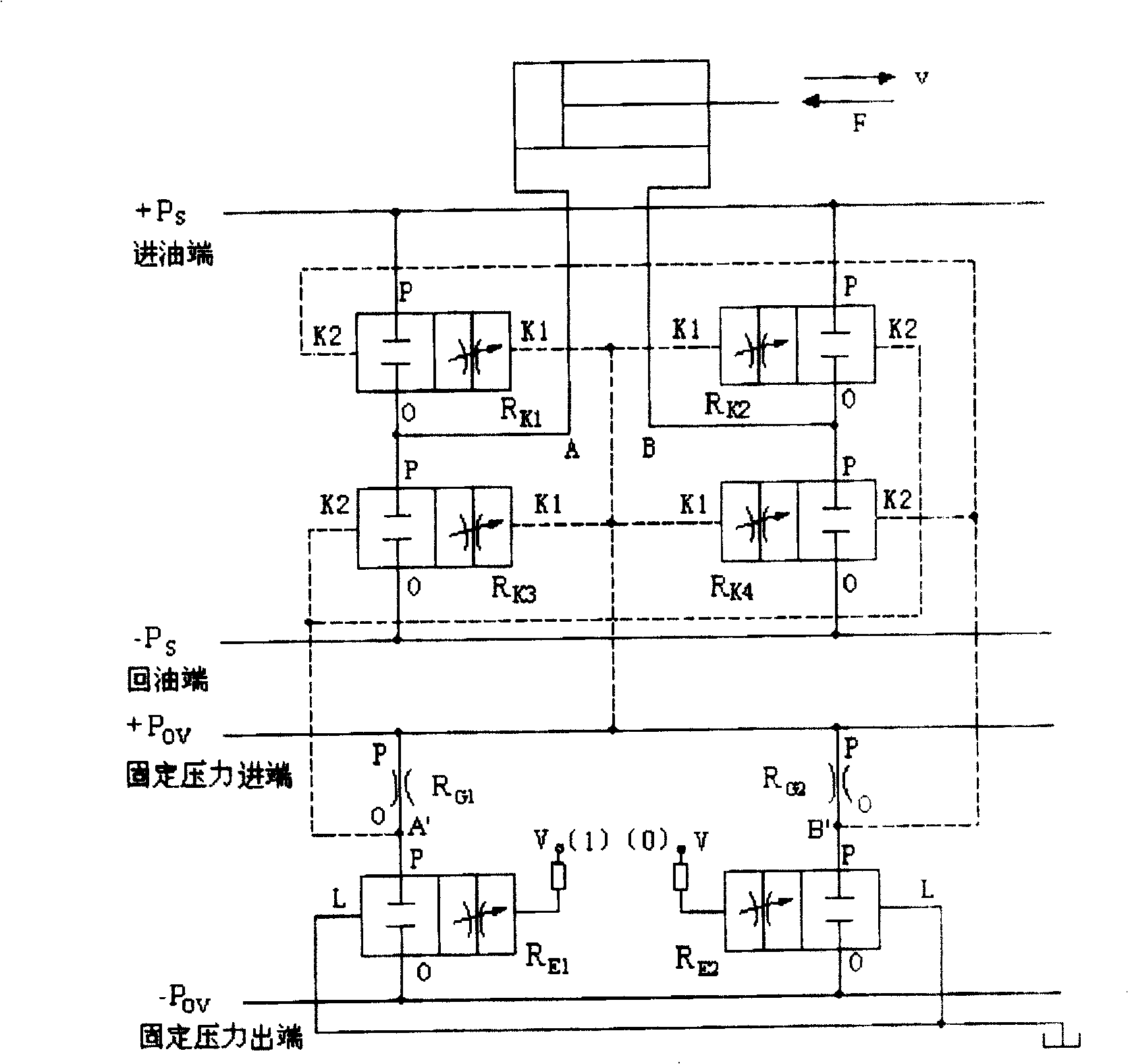

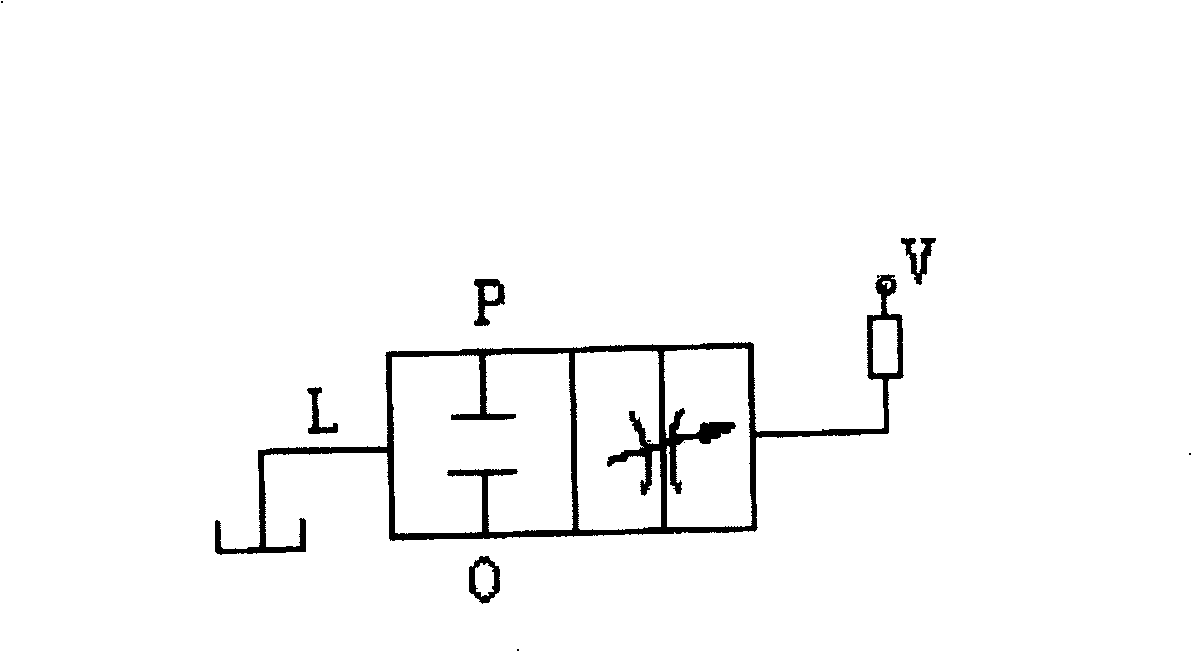

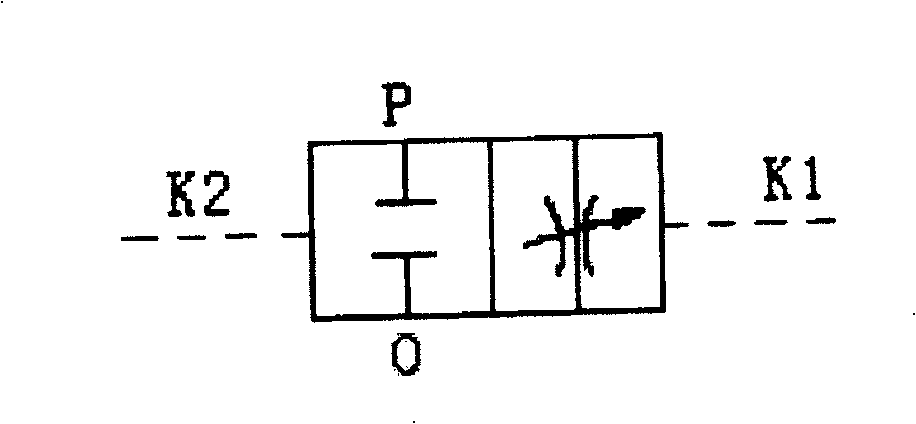

[0011] figure 1 It is a reversing fluid circuit composed of three basic fluid resistances. R K1 with R K3 concatenated together, R G1 with R E1 concatenated together, R K2 with R K4 concatenated together, R G2 with R E2 They are connected in series; the hydraulic resistance after series connection is rigidly sealed in the channel body of the hydraulic manifold. R K1 , R K2 , R K3 , R K4 K 1 Control port and +P OV connected together, A' and R K2 , R K3 K 2 Control port connection, B' and R K1 , R K4 K 2 The control ports are connected together; the connection between each control oil port is realized through the oil circuit in the channel body.

[0012] Run the process as follows: from R E1 V terminal, input command "1" digital signal, at the same time R E2 The V terminal input command "0". R E1 conduction, R E2 due. At this time, the liquid fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com