Glue line heating device of zigzag veneer longitudinal splicer

A technology of heating device and splicing machine, which is applied to the jointing of wooden veneers, devices for coating liquid on the surface, and glue containers, etc., which can solve the problems of wood chips failing to meet quality requirements, glue lines disengaging intermittently, and glue thread clogging Problems such as nozzles, to overcome uneven heating, uniform hot melt state, and easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

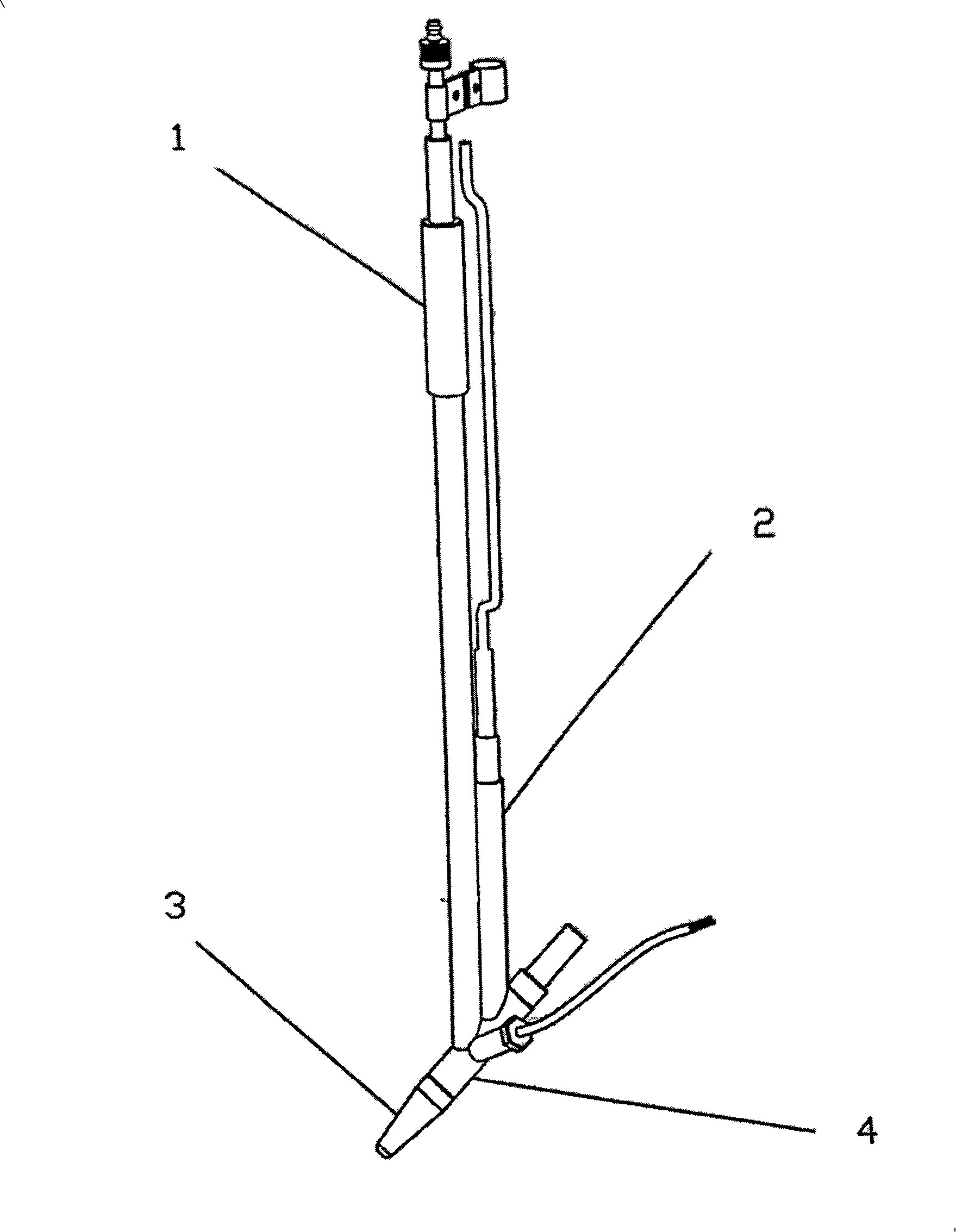

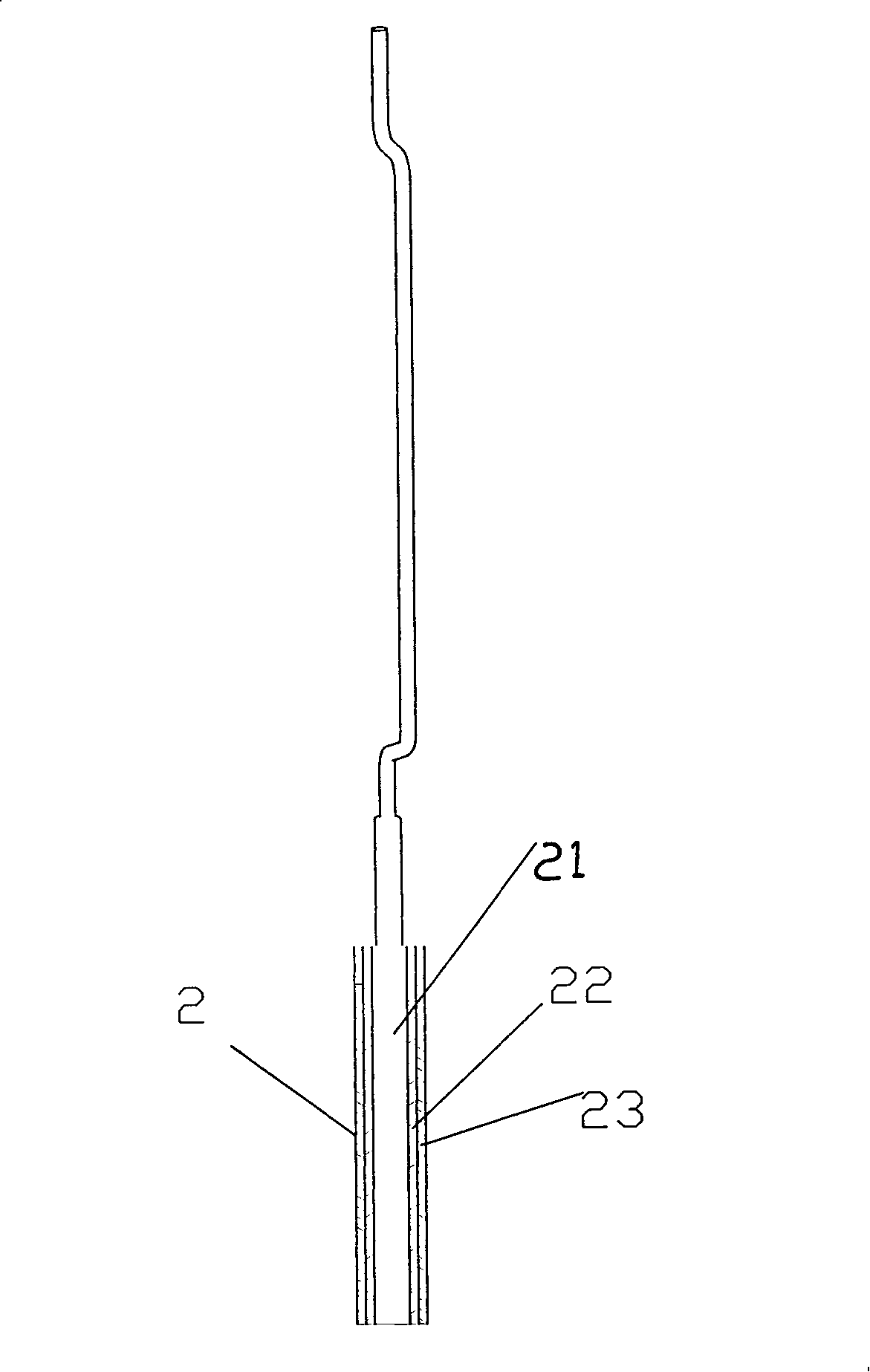

[0012] Such as figure 1 , figure 2 As shown, a glue line heating device of a toothed glue line veneer longitudinal splicing machine includes a nozzle 3, a heating head center tube 4, a glue line heater 1, and the glue line heater 1 is made of a stainless steel tube shell as a hot gas pipe Insulation tube, spiral heating wire composition (known technology, not shown in the figure), glue wire heater 1 is connected with heating head central pipe 4, and there is a central pipe heater 2 for heating the heating head central pipe 4 and heating head The central tube 4 is fixedly connected, and the inner cavity of the central tube heater 2 communicates with the inner cavity of the central tube 4 of the heating head. The central tube heater 2 is composed of a heating wire 21, an insulating layer 22, and a stainless steel shell 23; the material of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com