Energy saving heat equipment with open fire

A heating device and open flame technology, which is applied in cooking utensils, household utensils, applications, etc., can solve the problems of low heat utilization rate, heat energy dissipation, small heating area, etc., and achieve high heat utilization efficiency, full gas combustion, and full combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

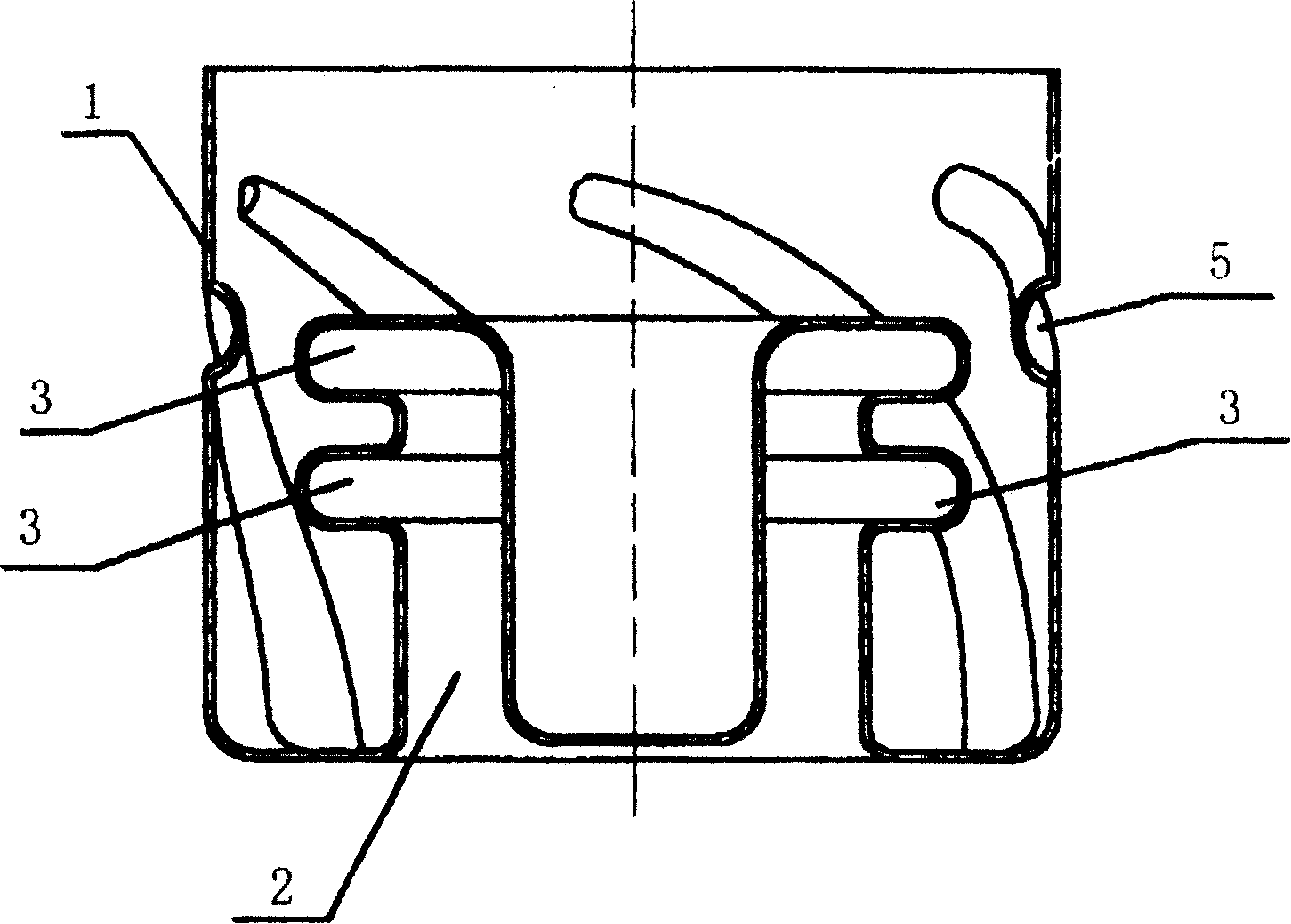

[0015] Such as figure 1 As shown, the open flame heating device includes a main body 1, and the bottom of the main body 1 is provided with an annular, deep concave fire chamber 2, and the width of the fire chamber 2 increases from the bottom to the outside at two places to form corresponding two ring-shaped energy storage The chamber 3 and the two annular energy storage chambers 3 are arranged in layers up and down.

Embodiment 2

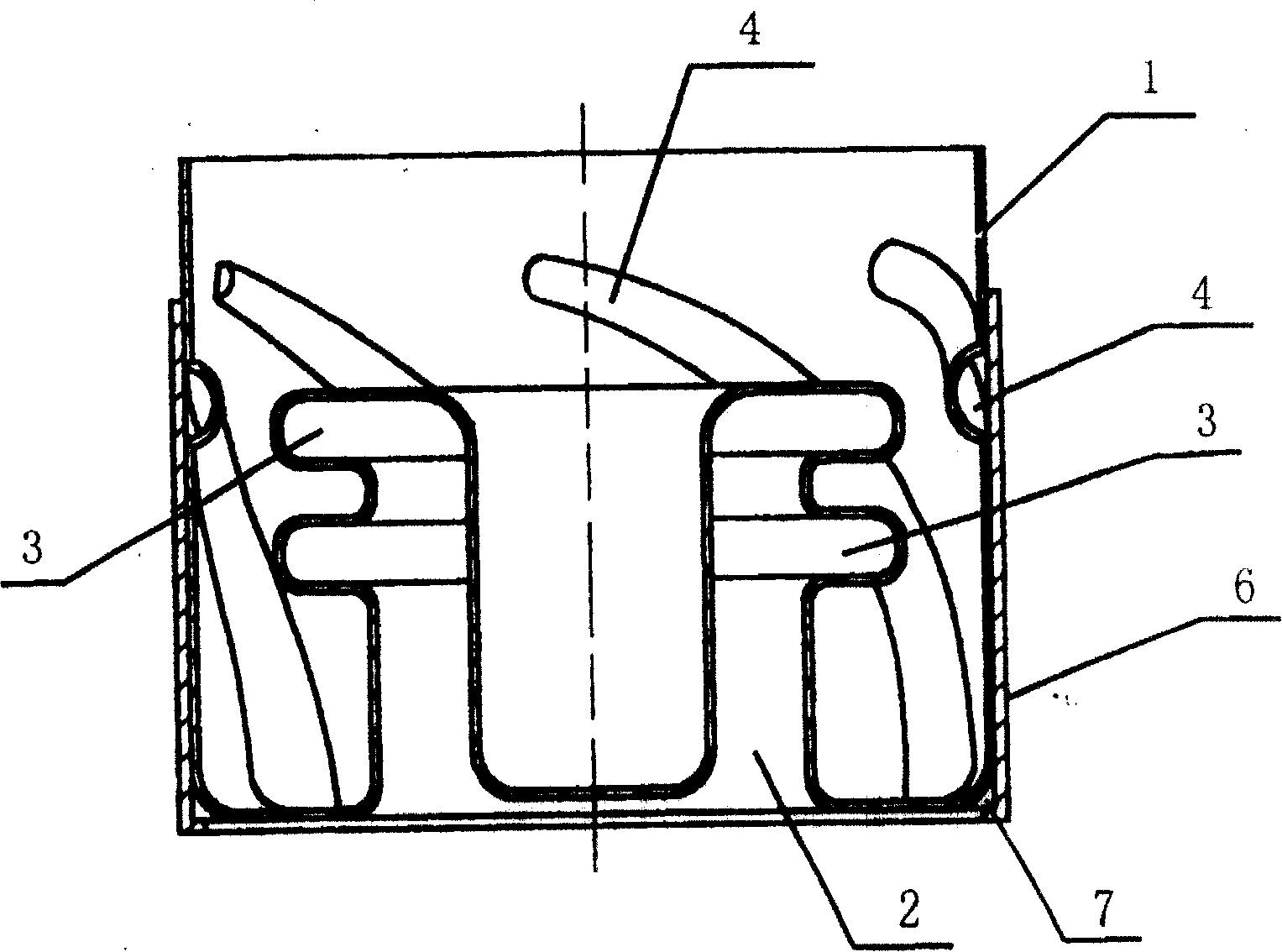

[0017] Such as figure 2 As shown, the open flame heating device includes a main body 1, and the bottom of the main body 1 is provided with an annular, deep concave fire chamber 2, and the width of the fire chamber 2 increases from the bottom to the outside at two places to form corresponding two ring-shaped energy storage Cavity 3, two annular energy storage cavities 3 are arranged up and down in layers; the outer surface of the main body 1 is provided with a plurality of narrow upper and lower wide flat spiral grooves 5, and the lower end of the groove 5 starts from the bottom of the main body 1 and coils along the side wall of the main body 1 On the other hand, the periphery of the groove 5 is an outer cover 6 matched with the outer surface of the main body 1, and an exhaust channel 4 for the passage of waste heat gas is formed between the outer cover 6 and the groove 5, and the lower edge of the outer cover 6 is flat with the bottom surface of the main body 1, and The oute...

Embodiment 3

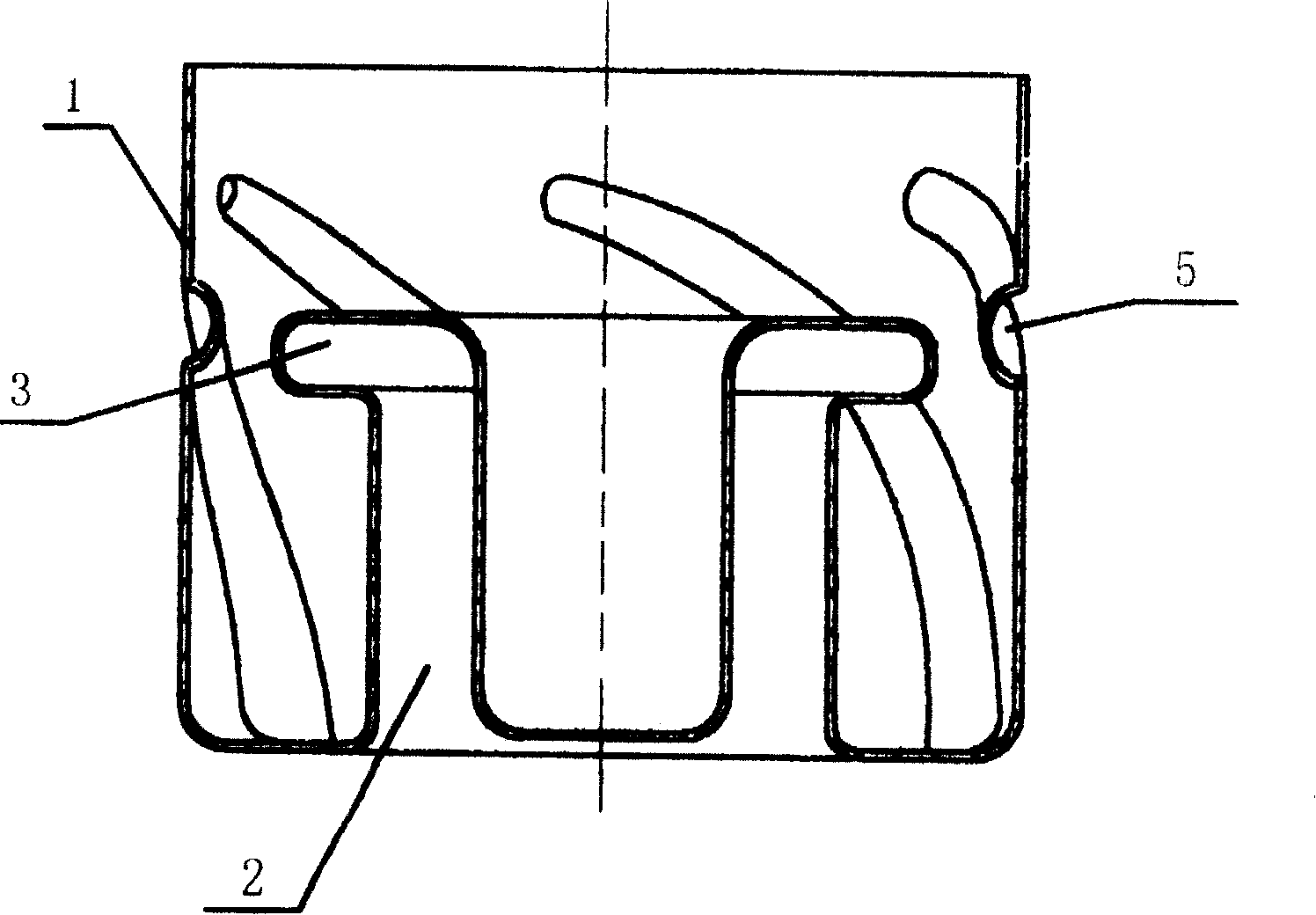

[0019] Such as image 3 As shown, the open flame heating device includes a main body 1, and the bottom of the main body 1 is provided with an annular, deep concave fire chamber 2, and the inner width of the fire chamber 2 increases outward at the bottom to form a corresponding annular energy storage chamber 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com