Processing cartridge with power inputting buffer unit

A buffer device and power input technology, applied in the field of processing boxes, can solve the problems of shortening the service life and prone to problems of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

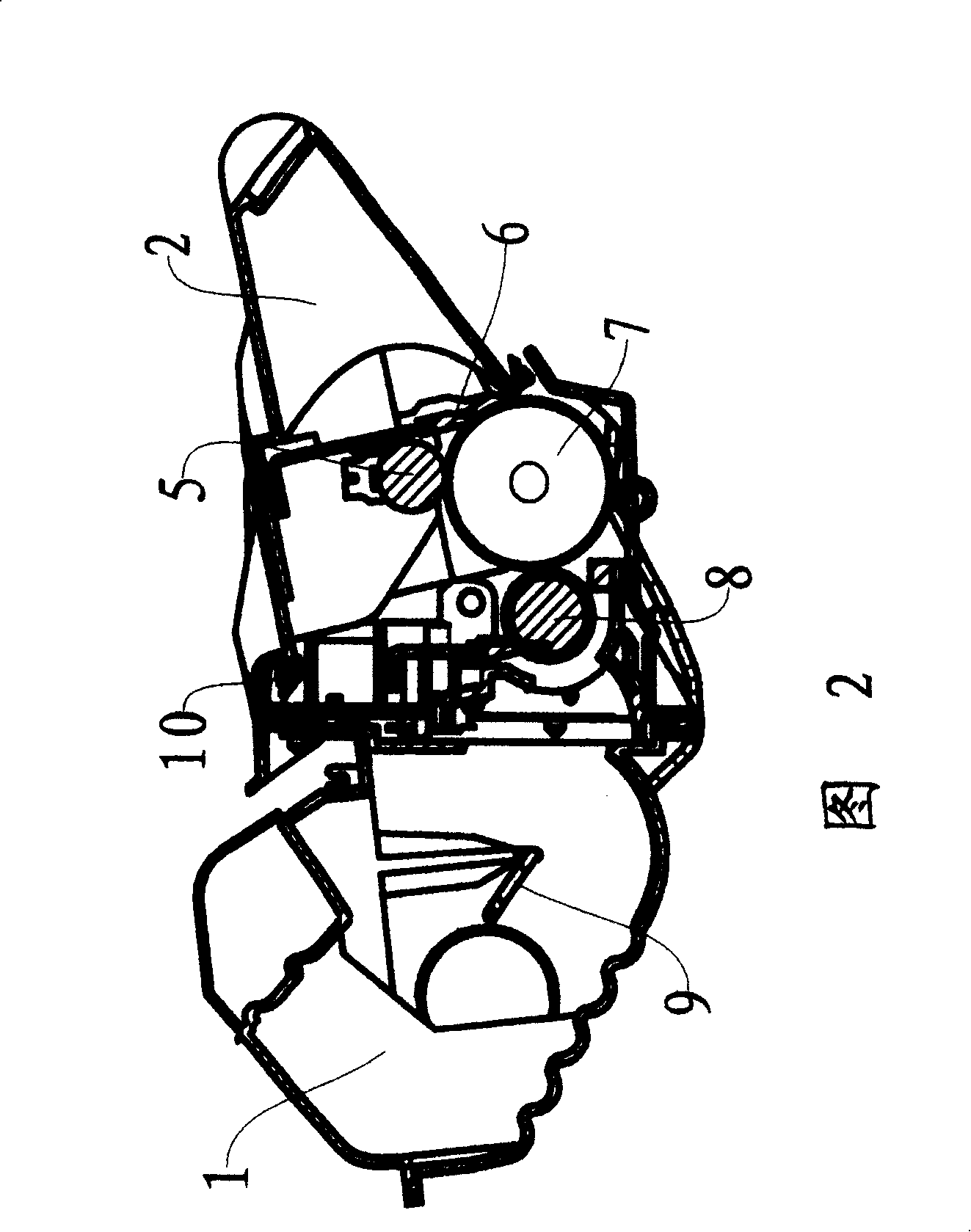

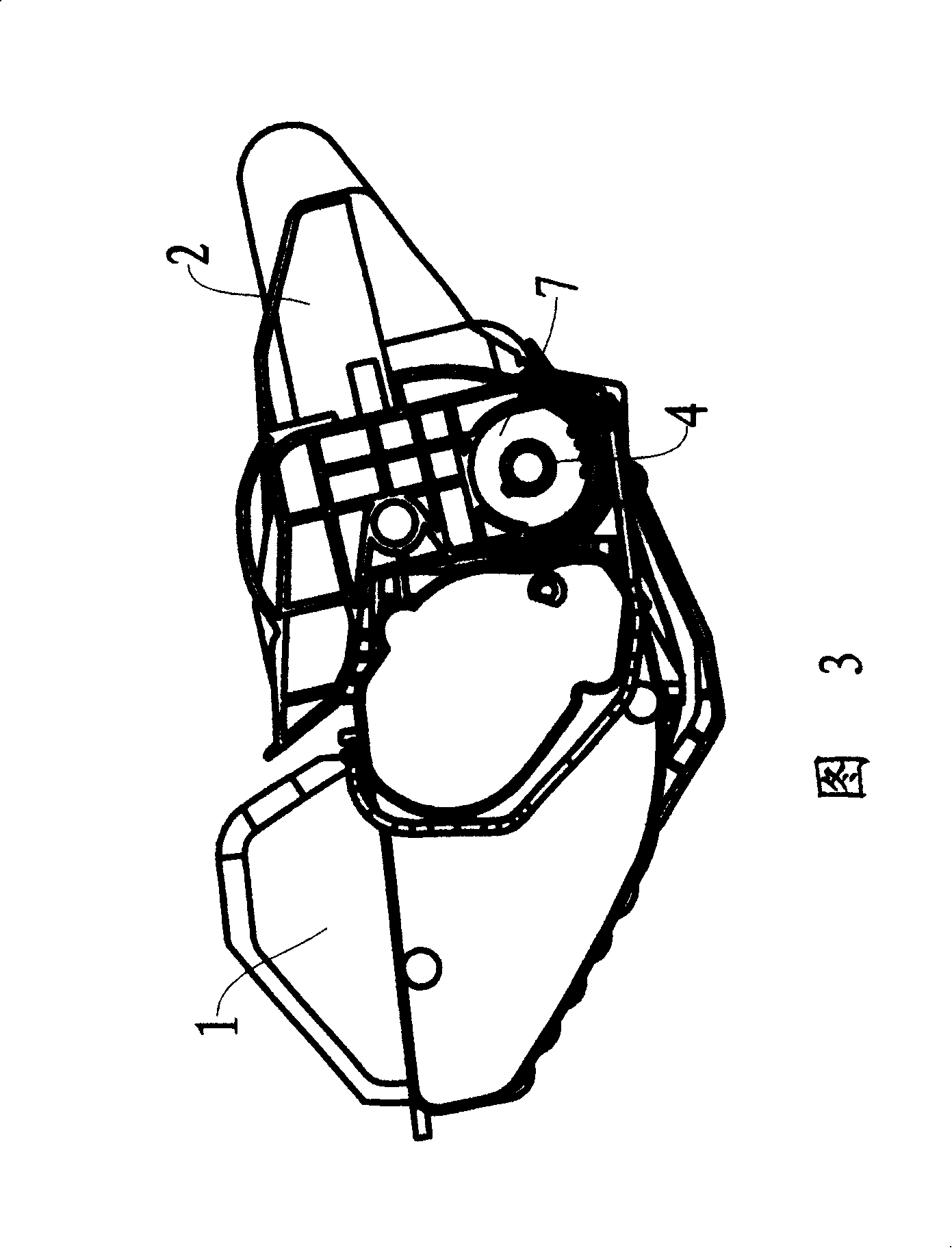

[0032] Referring to Fig. 1, the processing box is composed of a powder bin 1 and a waste toner bin 2, and the powder bin 1 and the waste toner bin 2 are rotatably connected within a small angle range through a pair of hinges 3 arranged on the side walls of the two bins , only one hinge 3 can be seen in Fig. 1, and the other hinge is on the relative invisible face. At the shaft end of the photosensitive drum protruding from the side of the process cartridge, an axially protruding elastic torque receiving member is fixed, in this example, a torsion spring 4, when the process cartridge is placed in the electrophotographic image forming apparatus When it is used, it can cooperate with the power output end of the electrophotography image forming equipment to input the power of the moving parts of the process box such as the photosensitive drum, the stirring frame, the magnetic roller, and the charging roller.

[0033] Referring to Fig. 2, the processing box provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com