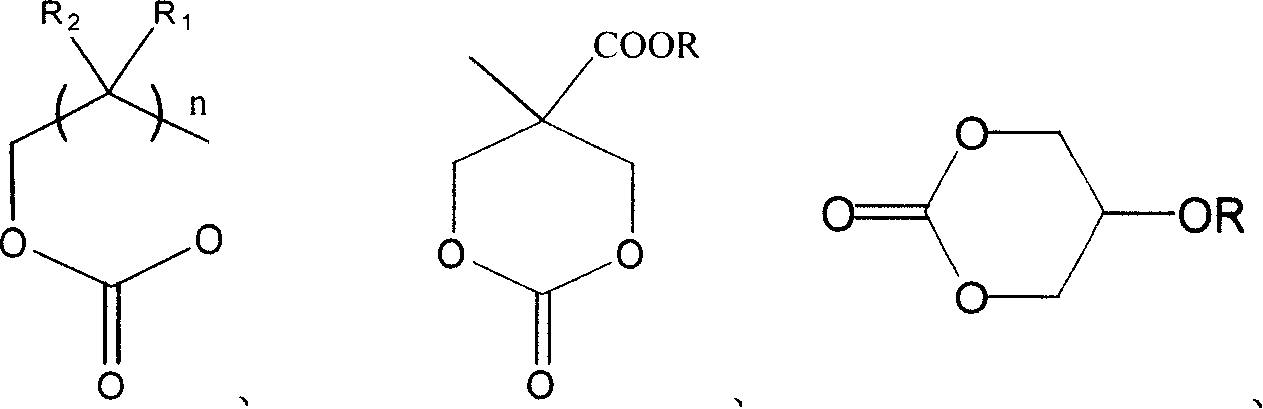

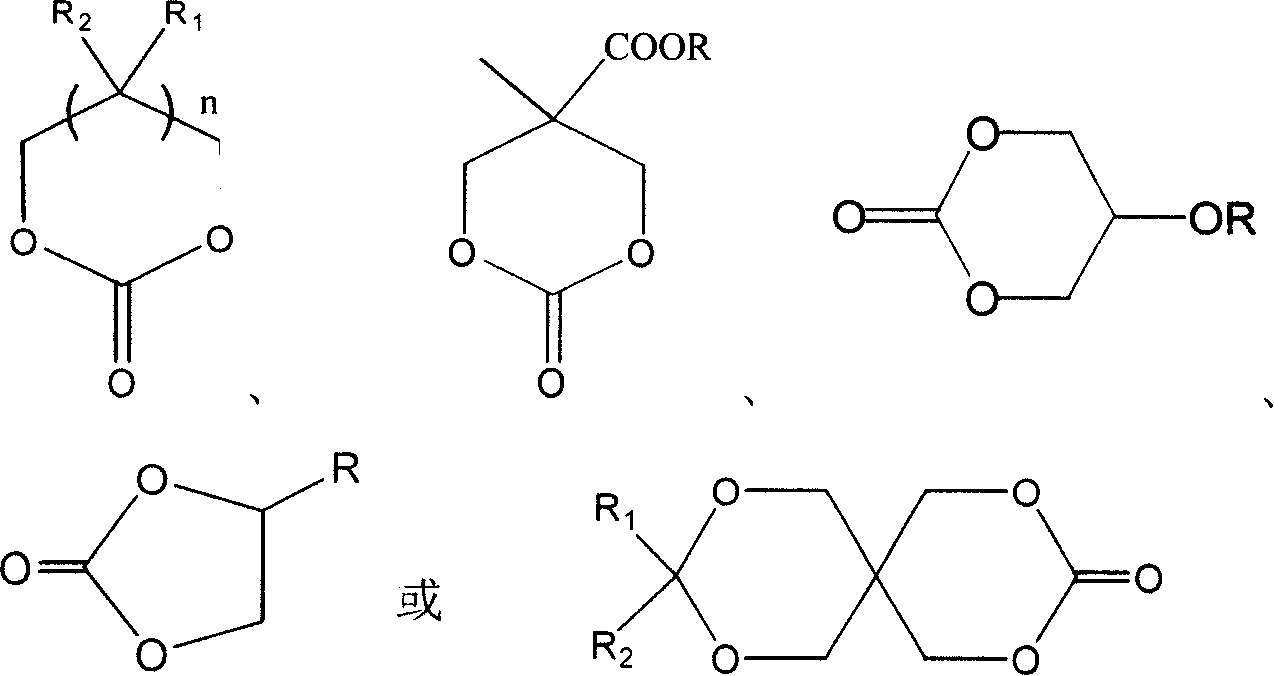

Application of cyclic carbnoic ester as initiator aid dental filling visible light curing filling compounding material

A technology of cyclic carbonate and composite materials, applied in dental preparations, dentistry, dental prosthesis, etc., can solve problems such as human toxicity, achieve low biological toxicity, reduce biological toxicity, and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] Dissolve 0.1536g visible light initiator CQ in 38.04g TEGDMA, mix with 114.12g UDMA and prepare UDMA / TEGDMA proportioning is 75wt%: 25wt%, CQ content is the organic resin system (I) of 0.1wt%, fully stirs and makes system mix Evenly, put in a dark room for later use.

[0014] Take by weighing 0.0511g of 5-methyl-5-formic acid benzyl trimethylene cyclocarbonate in a 25mL beaker, then add 9.9012g of the above-mentioned organic resin system (I) to it, fully stir it to mix uniformly, and obtain a mixture containing 0.5 wt % Cyclocarbonate Resin Mixture. Then add 10.6846g of barium borosilicate glass (US ESSCHEM company) with an average particle size of 19 microns (the volume content is 40% of the total amount of the mixture) in the mixture, fully stir it to mix it evenly, and obtain the organic resin system and the inorganic filler Composite material system with a volume ratio of 60:40. In the dark room, after the composite material system was left to stand for 12 hours, ...

example 2

[0016] Dissolve 2.2647g visible light initiator CQ in 2.14g 1.6-hexanediol dimethacrylate (HDDMA), mix with 40.66g EO-BISGMA (Mn=1700) and prepare EO-BISGMA / HDDMA proportioning ratio is 95wt%: 5wt %, the organic resin system (II) with a CQ content of 5wt%, fully stirred to make the system evenly mixed, and placed in a dark room for later use.

[0017] Weigh 1.41g of trimethylene cyclic carbonate in a 25mL beaker, then add 13.09g of the above-mentioned organic resin system (II) into it, stir well to make it evenly mixed, and obtain a cyclic carbonate resin mixture containing 9.7wt%. Then add 0.47g (volume content is 80% of the total amount of the mixture) of fumed silica filler AEROSIL OX50 (Germany DEGUSSA company) with an average particle diameter of 40 nanometers in the mixture, fully stir it to mix it evenly, and obtain the organic resin system A composite material system with a volume ratio of 20:80 to inorganic filler. In the dark room, after the composite material syste...

example 3

[0019] Dissolving 0.3513g CQ in 14.13g 1.3-butanediol dimethacrylate (BDDMA), mixed with 56.47g UDMA to prepare UDMA / BDDMA ratio is 80wt%: 20wt%, CQ content is the organic resin system of 0.5wt% (III), stir fully to make the system mix evenly, and place it in a dark room for subsequent use.

[0020] Weigh 0.4877g of 5-benzyloxytrimethylene cyclic carbonate in a 25mL small beaker, then add 23.89g of organic resin system (III) to it, fully stir and make it mix uniformly to obtain 2.0wt% cyclic carbonate Carbonate resin mixture. Then in this mixture, add average particle size and be that 12 nanometers fumed silica filler AEROSIL R711 (DEGUSSA company of Germany) 1.1263g (volume content is 40% of mixture total amount) and average particle size are 6.5 micron barium borosilicate glass (U.S.A. ESSCHEM company) 10.5695 grams (volume content is 20% of the mixture total amount), fully stirred to make it mix evenly, obtain the composite material system that the volume ratio of organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com