Enhanced 2-keto-L-gulonic acid production

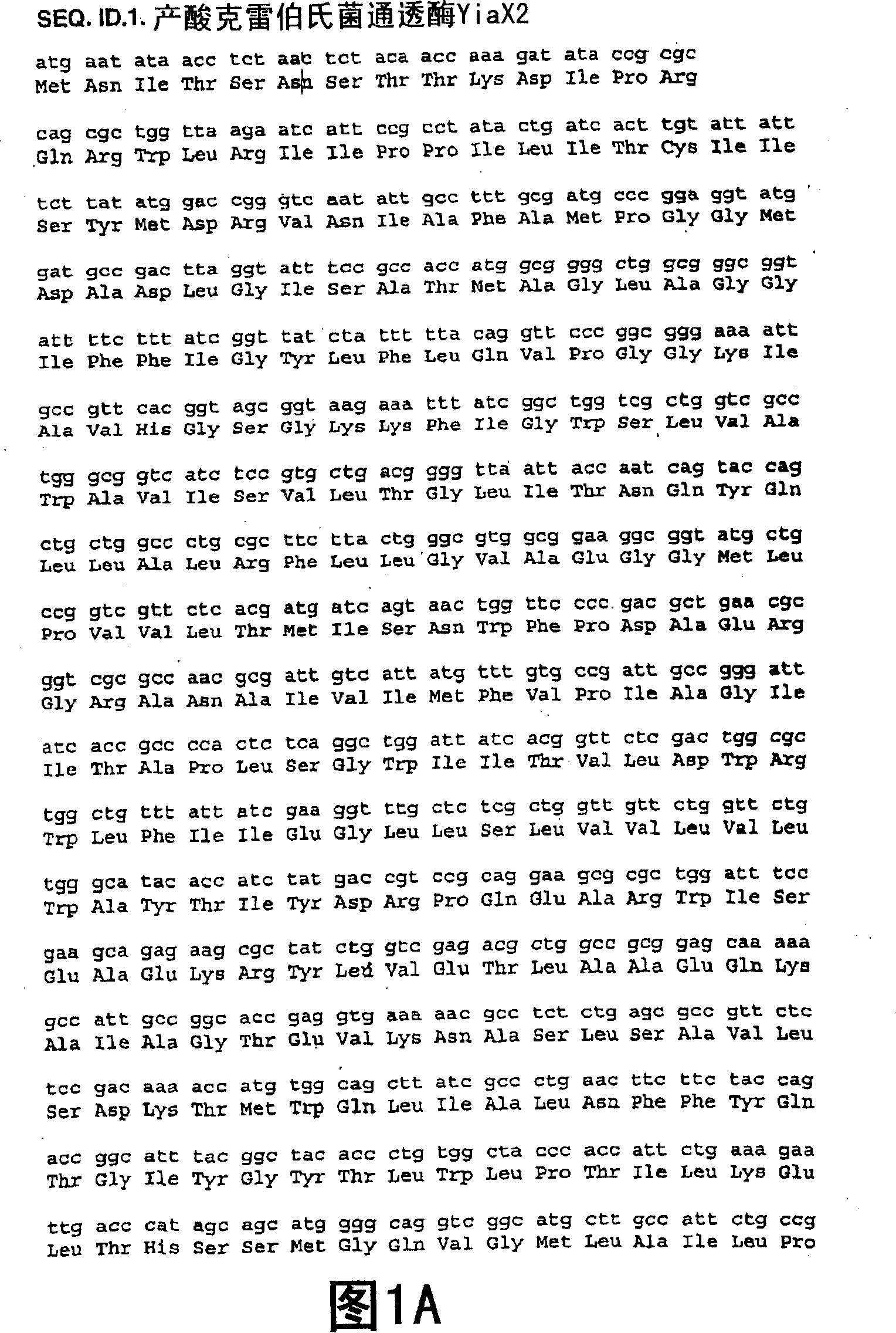

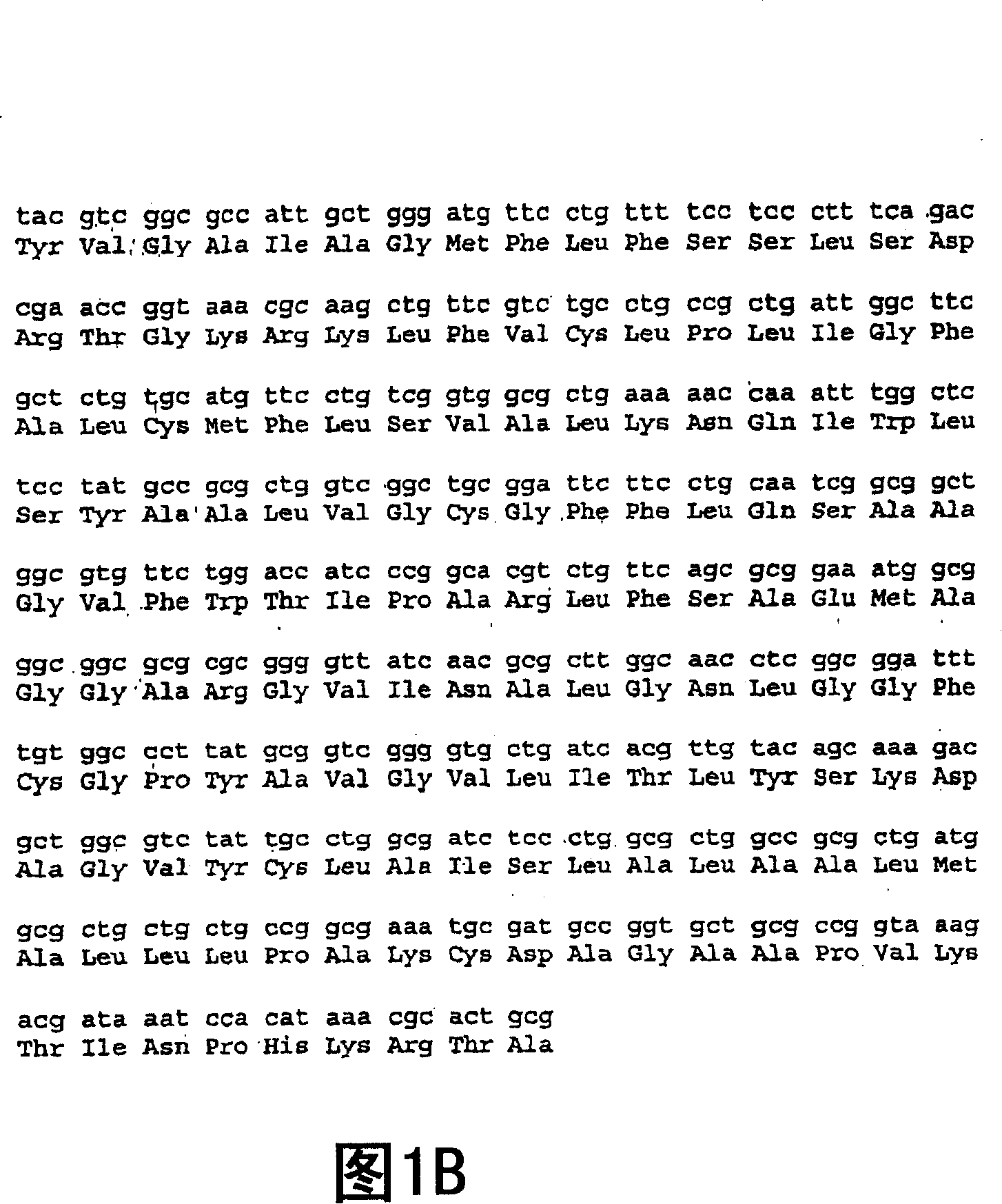

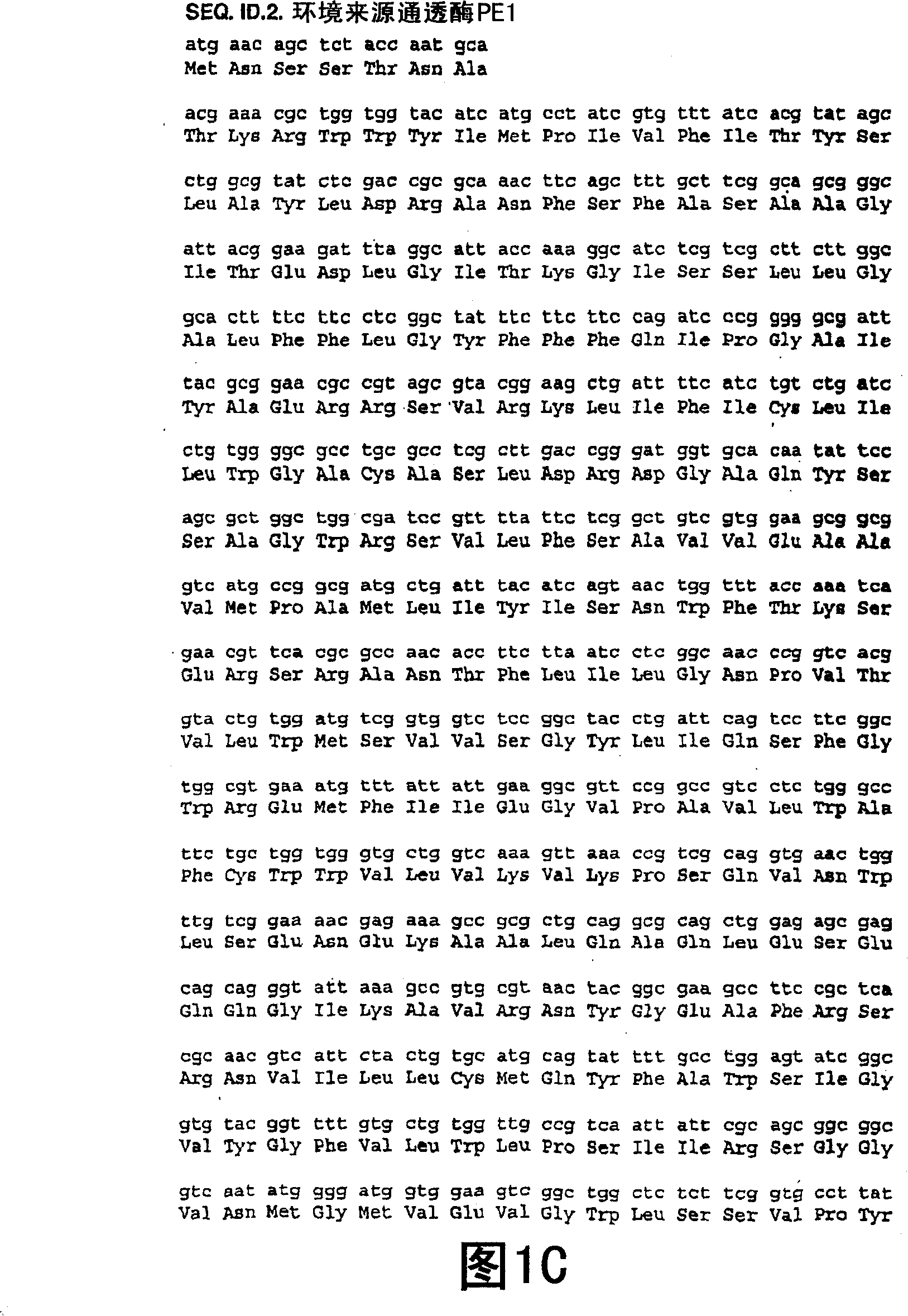

A technology of gulonic acid and 2-KLG, which is applied in the field of genome overexpression, can solve the problems of increasing the production of end products, difficult to ensure the enhanced production of end products or intermediates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0147] Materials and Methods

[0148] a. Plasmids, bacterial strains and culture medium: plasmid pBCL1920, Klebsiella oxytoca, Pantoea citrea 1392A. P. citrea strain 1392A is a variant of 39140 P. citrea. pD92 is described representing a vector containing the DKG reductase gene. US Patent No. 5,376,544. Murphy III medium contains fructose 0.5%, phosphate 1.6%, MgSO4.7H2O 0.2%, Soytone 0.2%, citrate 0.01%, (NH4)2S0 41%, trace salts such as Fe, Co, Mn, Zn in the ppm range and vitamins such as niacin, folic acid and B12; M9 medium contains 0.9% phosphate, 0.1% NaCl, 0.1% NH4Cl, MgSO4 0.0005%, CaCl2 0.025%; fermentation medium contains potassium phosphate (Potassium Phosphate) 1% , MgSO4 0.15%, Glutamate 1.5%, Fructose 2.5%, Ammonium Sulfate 0.1% and a vitamin blend containing Biotin, Thiamine, Pyridoxine, Riboflavin, Niacin, Folic Acid and B12, and Trace metal mixture solution of iron, Zn and Mn ions at 10-100 ppm level; transport assay medium containing 100 mM potassium phos...

Embodiment II

[0156] Example II provides that transporters of substrates may be the basis for rate-limiting factors of whole-cell biotransformation

[0157] This example illustrates the key steps in the formation of 2KLG from glucose that can be compartmentalized into 4 fractions (Figure 5). The key intermediate 2,5-DKG was produced in Pantoea citrea at a rate of 14-15 g / l / hr by three periplasmic enzymes (Sonoyama et al., APPl. Environ. Microbiol., 1982, 43: 1064- 1069). The second component is the rate at which DKG is required to be transported within the cytoplasmic space of the cell. The third is the rate of conversion of DKG to 2KLG by DKG reductase (US Patent No. 5,032,514). Conversion of DKG to 2KLG is not rate-limiting when DKG reductase is overexpressed. In our current 2KLG production fermentation, inducible plasmids are used to increase or decrease the specific reductase activity relative to our general fermentation (currently using pD92), where the DKG reductase is under the co...

Embodiment III

[0164] Example III provides evidence that substrate transport into cells for biotransformation is indeed the rate-limiting step

[0165] Cell pellets from three different times of the fermentation process, seed-flask stage, fructose-fed stage and glucose-fed stage, were collected and processed as described in the experiments. Using DKG uptake assays for these cell types, the rates of DKG uptake (introduction of DKG for conversion to KLG) were determined to be 0.5 g / l / hr, 2.7 g / l / hr and 2.75 g / l / hr (Figure 9). The rate of DKG input is equal to the rate of KLG output. This result therefore demonstrates that the rate of biotransformation of DKG to KLG is dependent on the rate of import of 2,5-DKG into cells. The present invention will thus demonstrate that by increasing the DKG uptake transporter by overexpression, the rate of 2,5-DKG import will be enhanced, and thus the rate of 2KLG production will be enhanced. An expert in the field can imagine that the key limiting factor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com