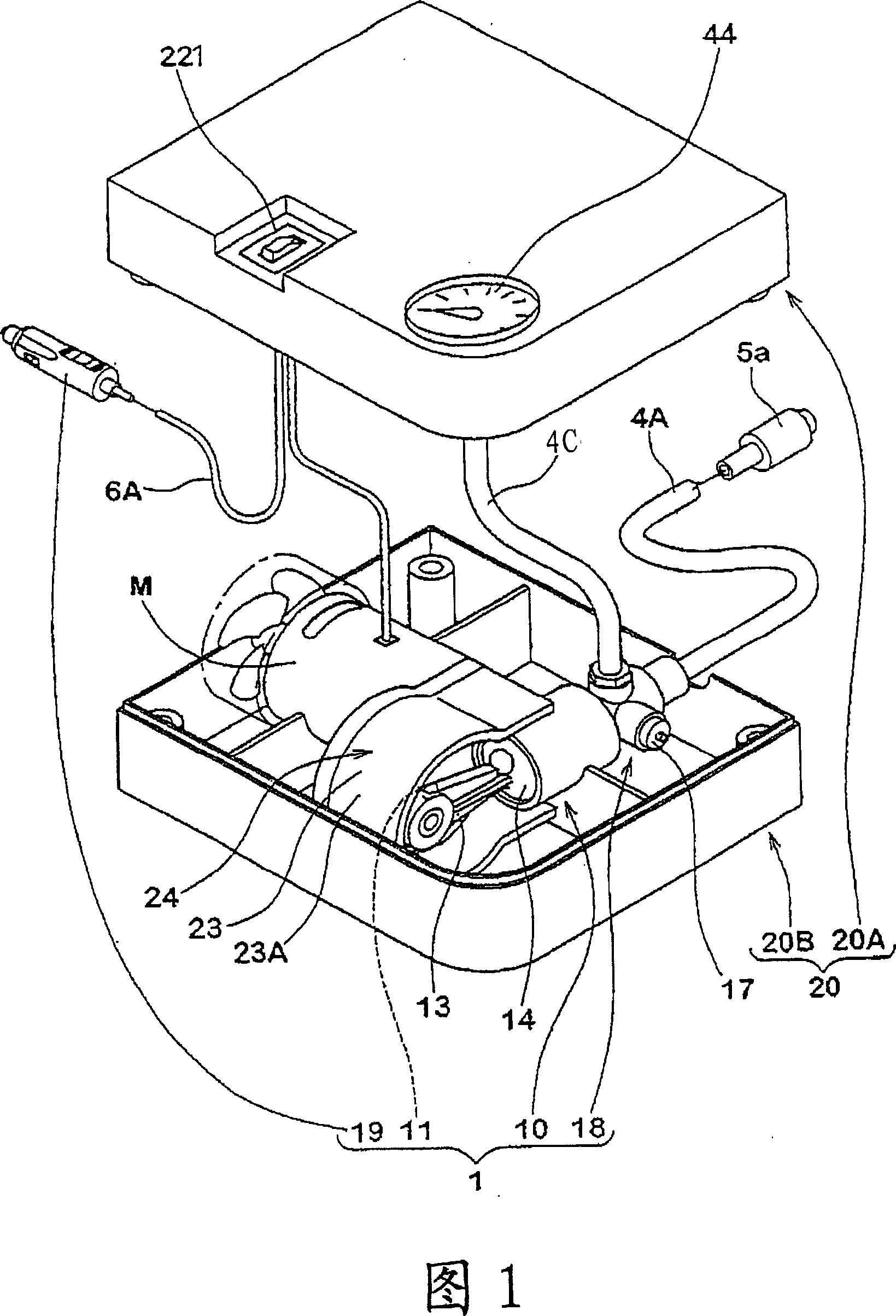

Small and simple aerating device

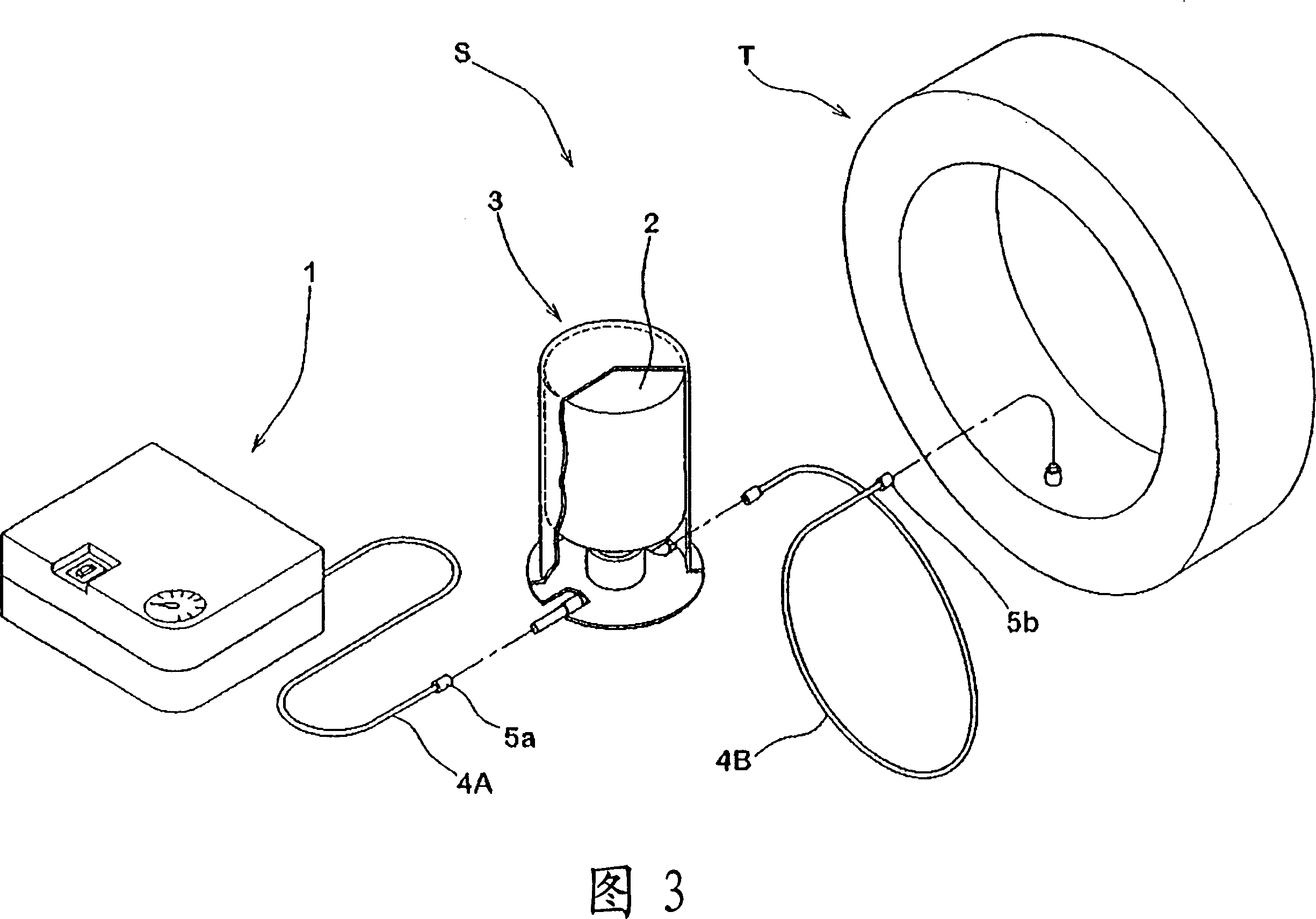

A filling device and air technology, used in transportation and packaging, vehicle maintenance, vehicle maintenance/repair, etc., can solve problems such as the decline in air filling capacity, and achieve the effect of reducing friction, reducing force, and practical emergency repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

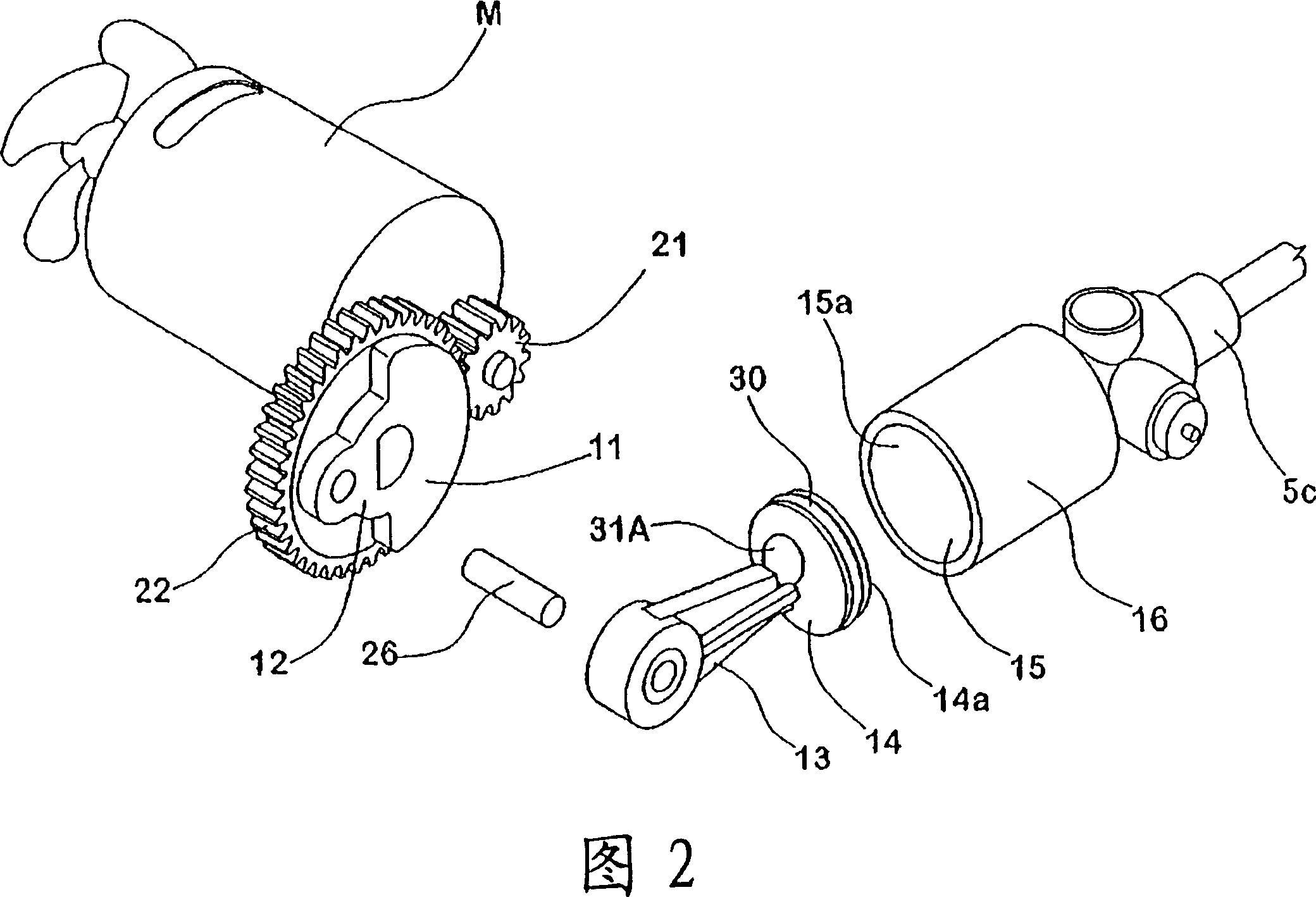

Method used

Image

Examples

Embodiment 1 Embodiment 2 comparative example 1

[0079] Shape V Type V Type O Type

[0080] Material NBR silicone rubber NBR

[0081] Boost performance 25 degrees C 5 minutes 56 seconds 6 minutes 5 seconds 5 minutes 57 seconds

[0082] Boost performance - 30 degrees C 6 minutes 4 3 seconds 8 minutes 21 seconds 8 minutes 42 seconds

[0083] Looking at the present invention, a rubber ring is provided between the piston and the inner wall of the cylinder. As mentioned above, because the rubber ring is V-shaped, it can solve the gap change between the piston and the cylinder caused by the inclination change of the integrated piston that cannot be solved by the O-ring. Problem, and because the gap is filled by the deformation of the outer rib of the rubber ring when the force is applied, the force on the piston is further reduced, and the durability of the product is improved by reducing friction. Again because of the expansion and contraction of the outer ribs of the above-mentioned rubber rings at low temperatures, the deform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com