Installation tools operated by fuels

A technology for installing tools and working, applied in the direction of nailing tools, manufacturing tools, etc., can solve problems such as the propellant package being stuck, the propellant package spontaneous combustion, etc., and achieve the effect of eliminating the possibility of multiple ignitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

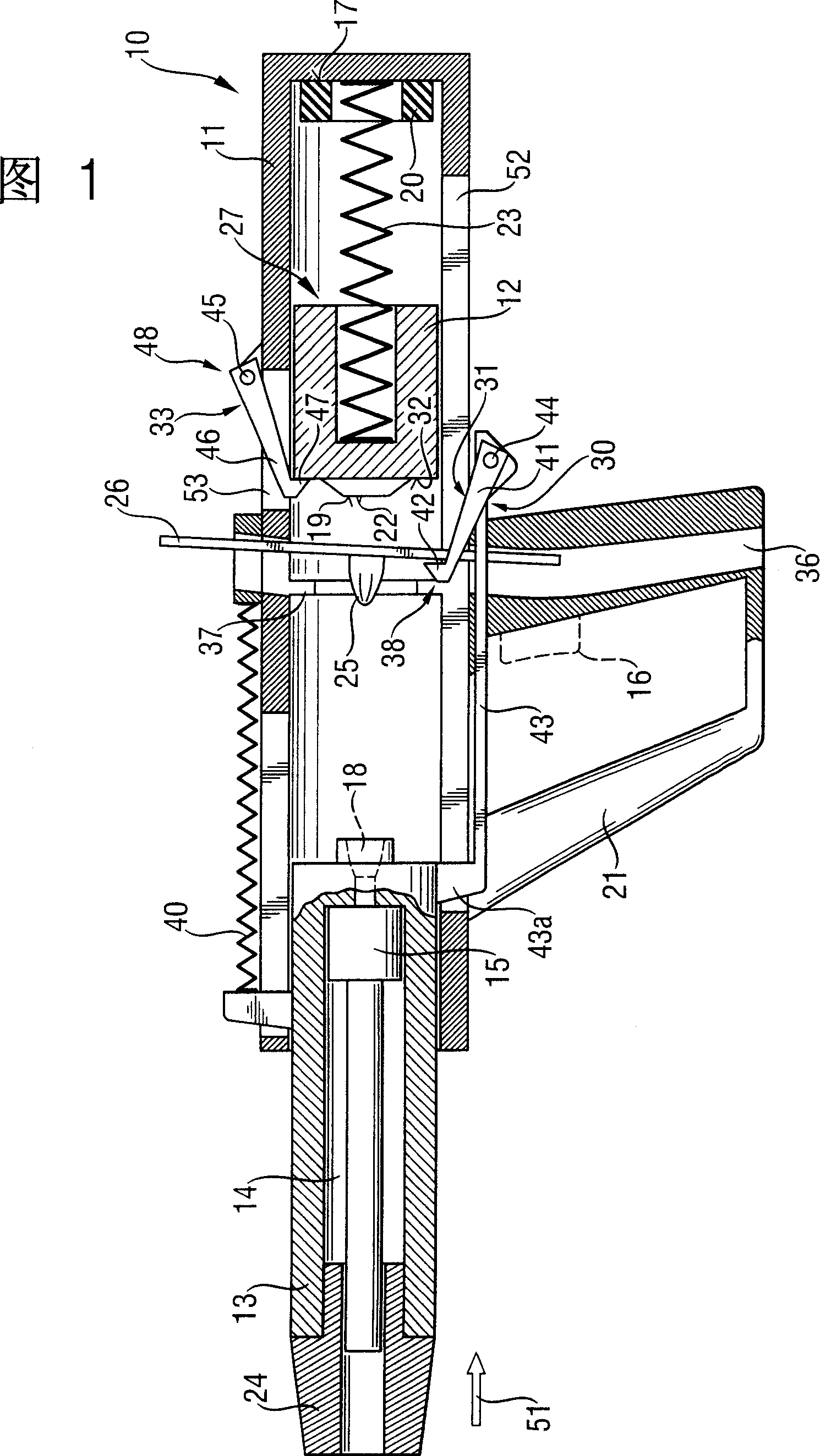

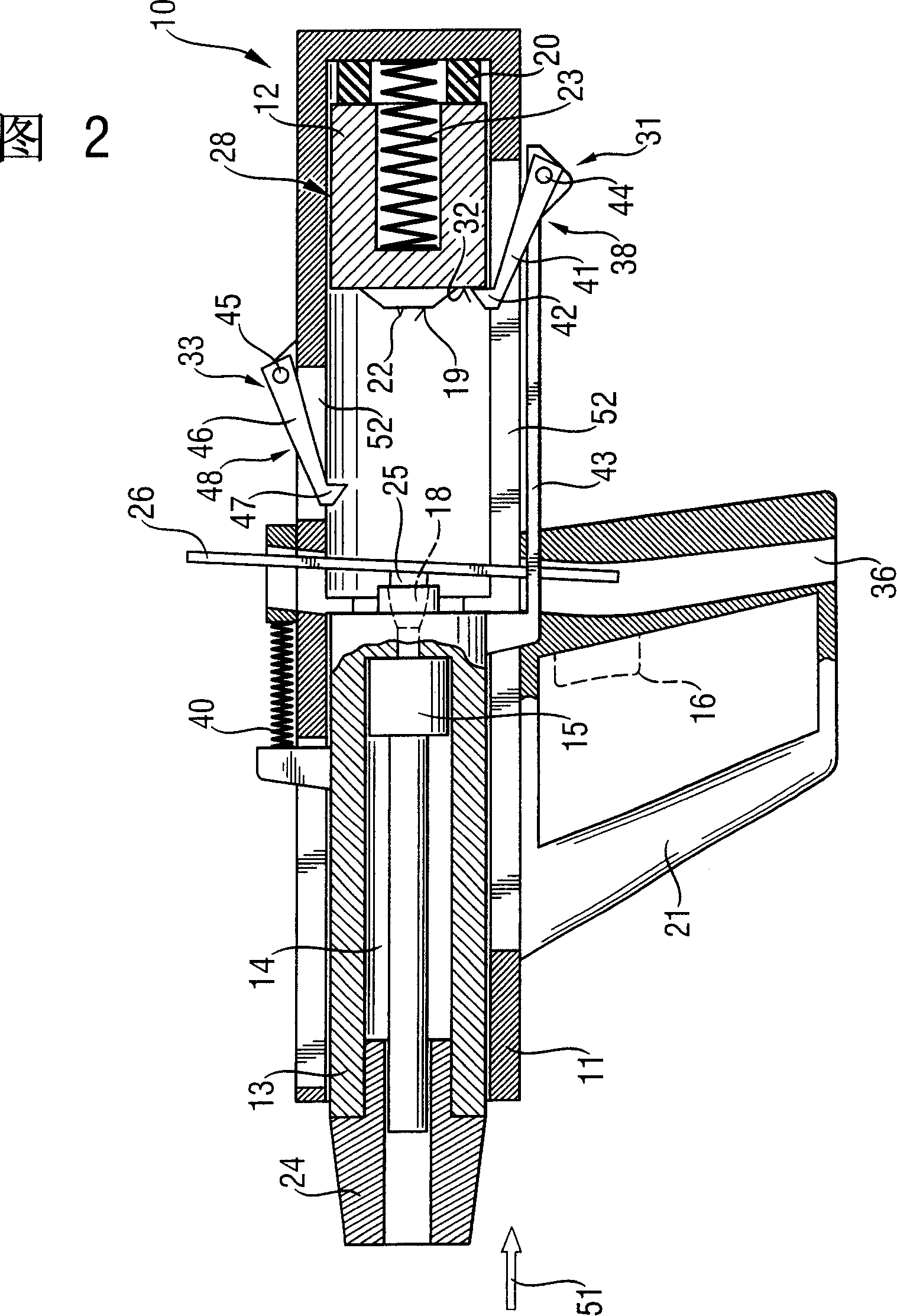

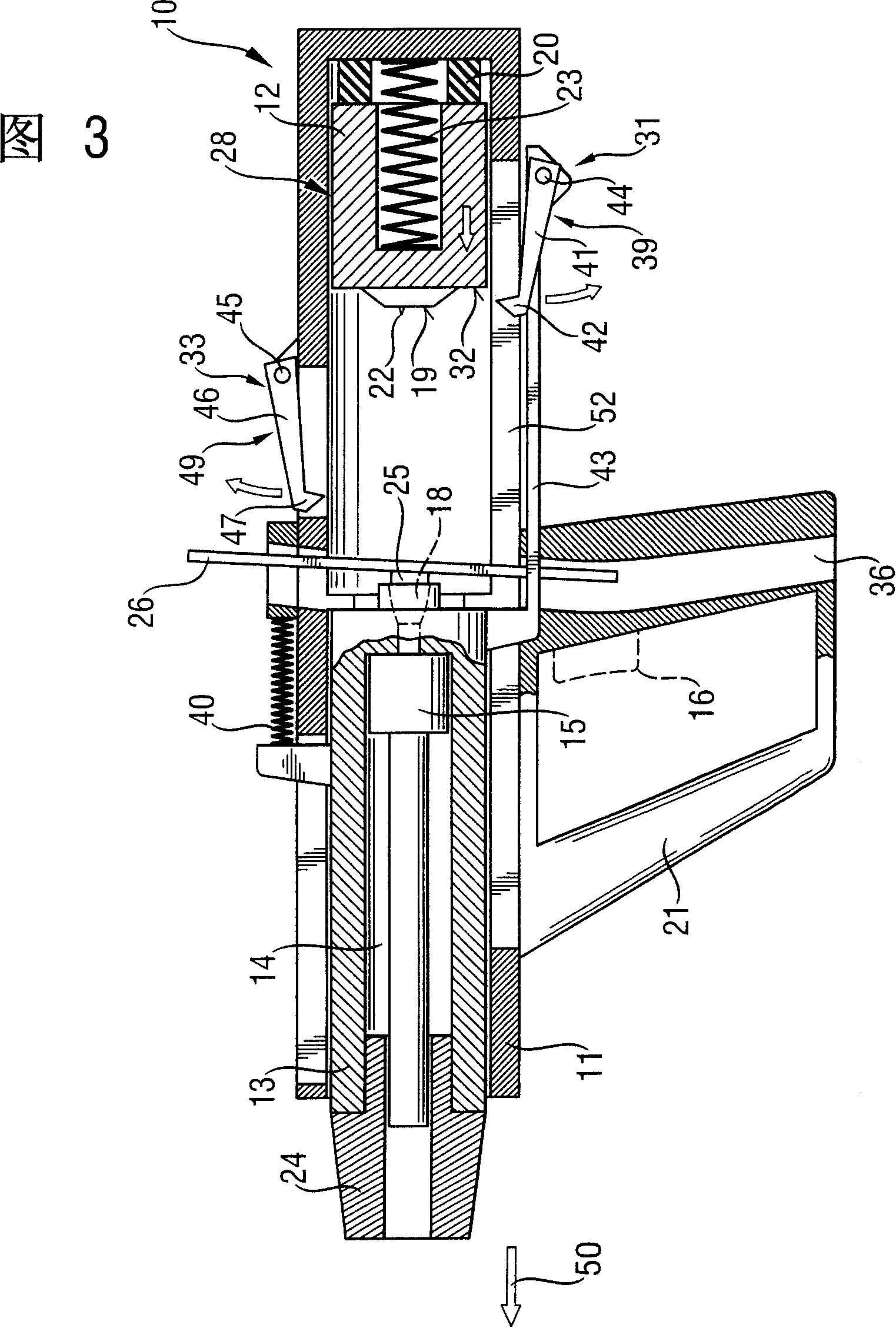

[0029] Figures 1 to 5 show the first embodiment of the present invention.

[0030] The installation tool 10 shown in FIG. 1 in its rest position has a piston guide device 13 housed in an integral or divided housing 11. The piston 15 is movably installed in the cavity 14 of the piston guiding device 13, and it can be driven by the propellant pack 25 or the expanded combustion gas or the like. In this embodiment, a handle 21 is also provided on the housing 11 with a trigger switch 16 for the user of the installation tool 10 to initiate the installation process. The handle 21 and the trigger switch 16 shown in FIGS. 1 to 5 are omitted and not shown in FIGS. 6 to 10. But these parts can also exist there. Obviously, in addition to the housing 11, the installation tool 10 shown here may also have other housing parts made of plastic or an external protective housing.

[0031] In this embodiment, the piston guiding device 13 is movably installed in the designed sleeve-shaped housing 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com