Precisive determining system of mechanical arm location and gesture in space

A space manipulator, precision testing technology, applied in mechanical measurement devices, mechanical devices, measurement devices, etc., can solve the problems of difficult debugging, complex structure, low safety and reliability, etc., to achieve low measurement costs, improve work efficiency, Test for easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

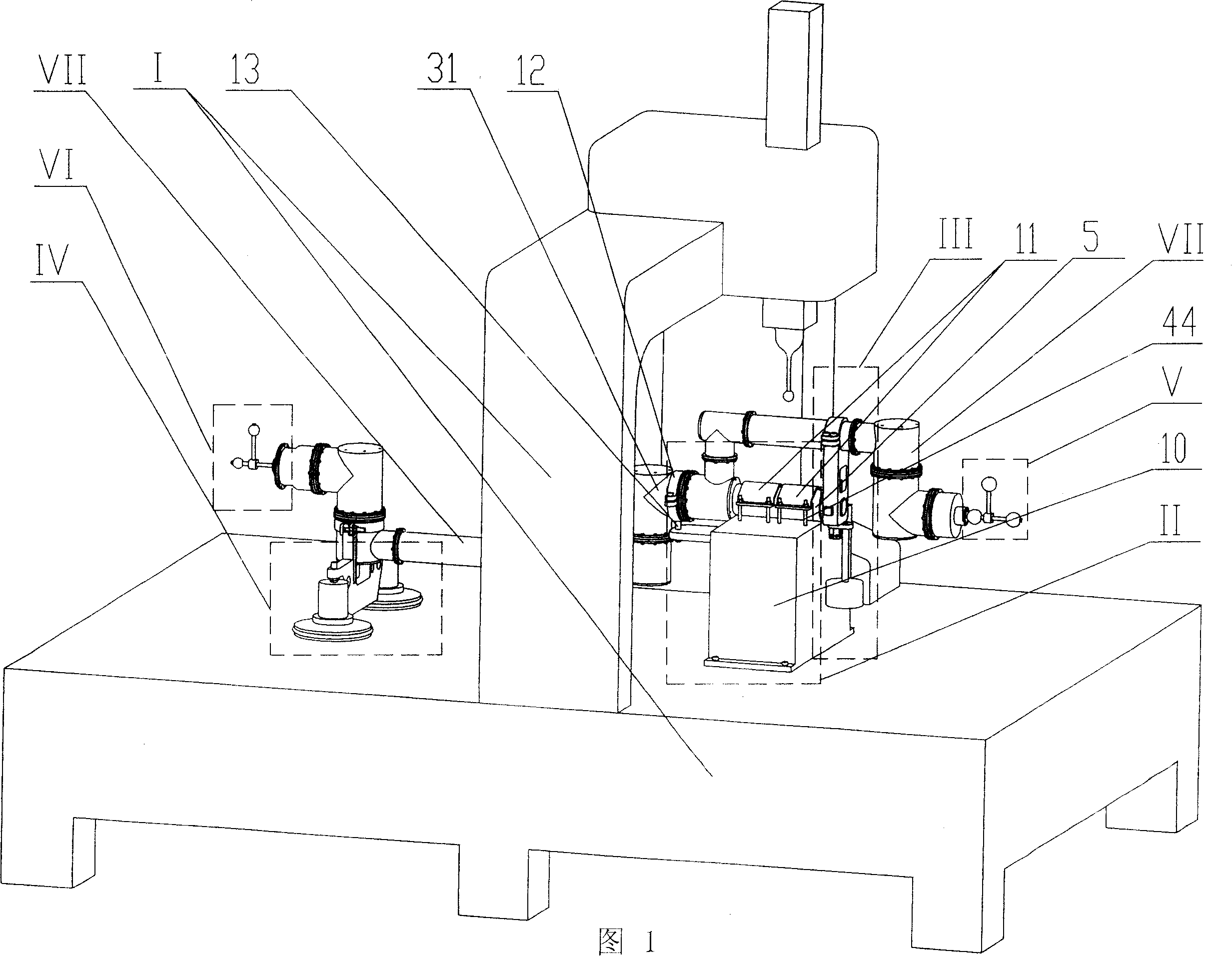

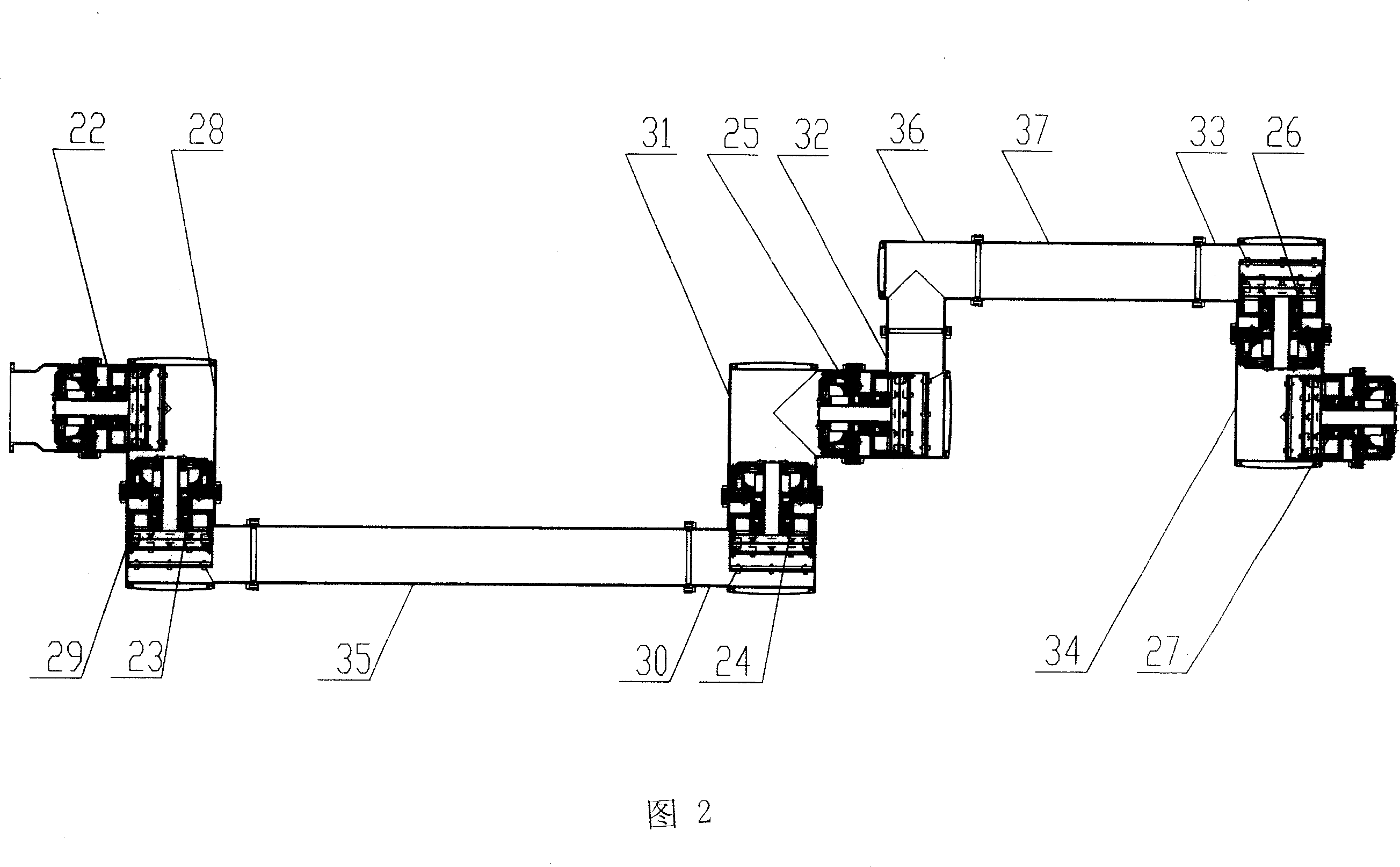

[0007] Specific implementation mode 1: The traditional air flotation system can only realize the two-dimensional plane movement of the system, and cannot realize the space movement required by the space manipulator. In order to test the pose accuracy of the space manipulator, all joints of the space manipulator need to move together, so that the resulting pose accuracy is the pose accuracy of the entire space manipulator. Therefore, this embodiment provides a system for testing the pose accuracy of a manipulator with spatial three-dimensional motion. The space manipulator that can be tested by the test system described in this embodiment has six degrees of freedom and can realize The robot arm with three-dimensional movement in space can be any space robot arm capable of three-dimensional movement, or it can be a space robot arm with six rotating joints as shown in Figure 2, and the space robot arm VII shown in Figure 2 , has applied for a patent, the application number is 200...

specific Embodiment approach 2

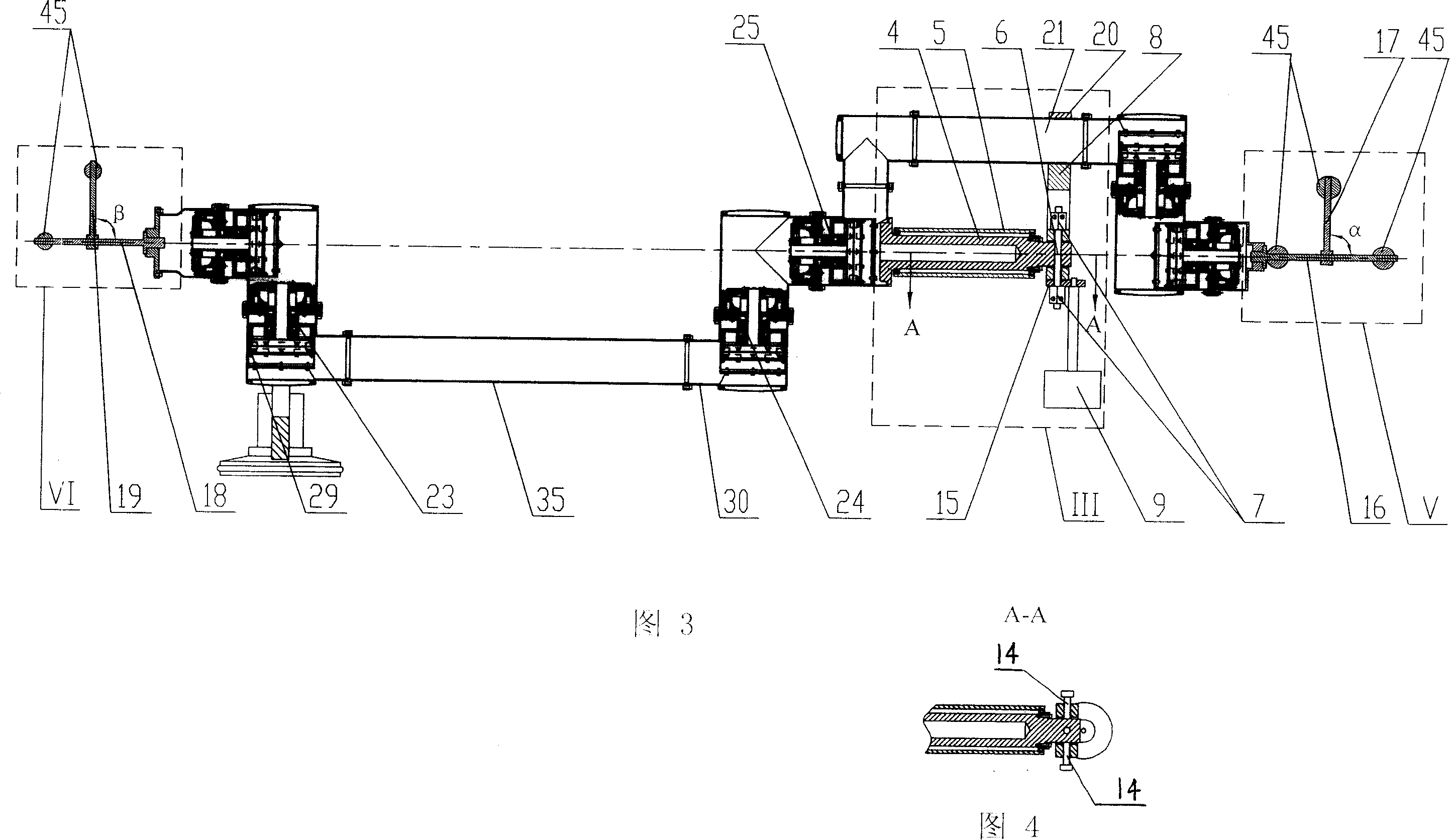

[0019] Specific embodiment two: with reference to Fig. 1, Fig. 3, Fig. 4, Fig. 5, an adjusting bolt 14 (referring to Fig. 4 ) is arranged between the second bracket 8 and the screw rod 6 on the rotating support system III described in the present embodiment, which can By adjusting the relative position of screw rod 6, nut 7 and bolt 14 and second support 8, adjust the coaxiality of mechanical arm support shaft 4 and joint four 25; One end, the other end of the counterweight connector 15 is fixed to the second bracket 8 through the nut 7 and the screw rod 6, through the connection of the counterweight connector 15, the upper end of the counterweight 9 can be fixed conveniently.

specific Embodiment approach 3

[0020] Specific embodiment three: Referring to Fig. 1 and Fig. 3, the first connecting rod 16 on the end target V in this embodiment is consistent with the axis of the space manipulator VII, and the coordinate system can be conveniently established when it is consistent with the axis of the space manipulator VII; Another second connecting rod 17 is fixed on the connecting rod 16, and the included angle α between the second connecting rod 17 and the first connecting rod 16 is an angle greater than 0 degree and less than 180 degree; A metal ball 45 is respectively fixed on the two ends of 16 and one end of the second connecting rod 17, and the function of the metal ball 45 is to establish an auxiliary measurement coordinate system; Flange connection or direct screw connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com