Ventilated forced drainage type nano tungsten powder reducing furnace for industrial use

A nano-tungsten powder, an industrial technology, applied in furnaces, furnace components, furnace types, etc., can solve the problems of unfavorable dust removal of tungsten powder yield, affect the production level of nano-tungsten powder, and the water vapor cannot be discharged quickly, etc., to achieve Solve the effects of uneven reduction, less material loss and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

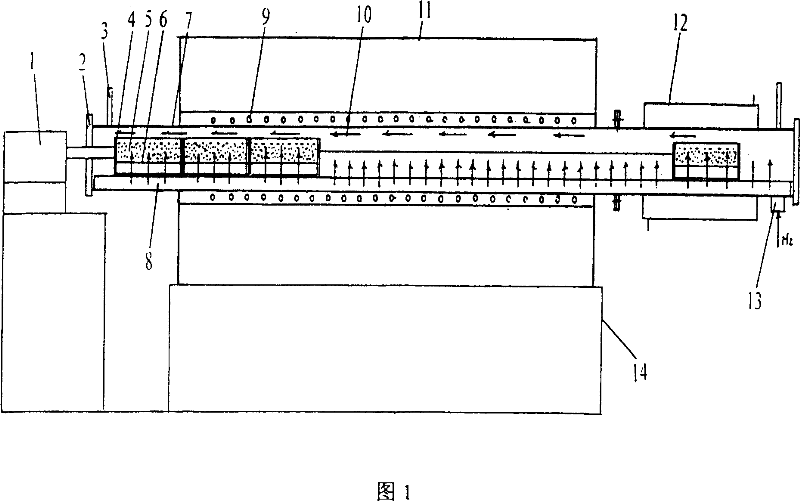

[0033] The gas-permeable and strong-drainage nano-tungsten powder reduction furnace with a production capacity of 1.42 tons / month should be designed as follows.

[0034] 1. Furnace tube preparation

[0035] Use Cr25Ni20 heat-resistant stainless steel plate or 1Cr18Ni9Ti stainless steel plate with thickness δ=4.5mm, combined welding to make two rectangular furnace tubes with rectangular cross-section, the furnace inner cavity height H=36mm, inner cavity width B=146mm, the furnace tube is heat-resistant The total length of the steel part is 2274mm, the length of the furnace tube in the water-cooling jacket is 665mm, the length of the furnace body is 1824mm, the length of the high-temperature zone of the furnace tube is 1424mm, and the heating in one zone is 32KW, and the length of the cooling water jacket is 480mm.

[0036] 2. Positive pressure for H 2 The porous air cushion is combined and welded with stainless steel plates with a thickness of δ=1mm, and there are 5 gas channe...

Embodiment 1

[0039] Example 1 Effect

[0040] The nano-amorphous tungsten oxide precursor powder produced by the ultrasonic spray heat conversion process in the air-permeable and strong-drainage nano-tungsten powder reduction furnace designed above, at 600 ° C; 60 minutes; H 2 Air pressure ΔP=0.005MPa; H 2 Sectional flow rate is 90ml / cm 2 Points; H 2 The air dew point is -15℃; the speed of pushing the boat is 7.12 boats / h; the loading capacity of the boat is 0.65g / cm 2 ;Under the condition of a total of 185g per boat, the produced nano-tungsten powder SAXS average particle size=30.3nm, BET specific surface area is 23m 2 / g, the daily output of tungsten powder (double tube) is 47.4kg / day, at the same time, in order to compare the reduction effect, the positive pressure in the above two furnace tubes is supplied to H 2 The porous air cushion is removed and changed to a conventional reduction furnace, and the gas supply method is to supply H along the axis of the furnace tube 2 gas. The...

Embodiment 2

[0042] Prepare a kind of garden-shaped furnace tube (single tube), and daily output is that the air-permeable strong drainage type nanometer tungsten powder reduction furnace of 8.3kg / day should be designed according to the following.

[0043] 1. Furnace tube preparation

[0044] The Cr25Ni20 heat-resistant stainless steel pipe with a thickness of δ=6mm and an inner diameter of φ70mm is 2.3 meters long, of which the water cooling jacket occupies a length of 450mm, the length of the furnace body is 1500mm, the length of the high temperature zone is 1.1 meters, and the heating power is 10KW. In the high temperature zone, two boats can be cooled simultaneously in the water cooling jacket.

[0045] 2. Positive pressure for H 2 The porous air cushion is made of a garden-shaped stainless steel tube with a diameter of φ=12mm and a wall thickness of δ=1.5mm. The holes at both ends are blocked, and the length L=2.28 meters. The two ends are fixed on the bottom of the garden-shaped fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com