Roller type leveling machine

A straightening machine and plate technology, which is applied in the field of forging equipment-roller straightening machine, can solve the problems of large contact stress, unfavorable inclination accuracy of movable beams and movable row work rolls, wear of work rolls, etc., and achieve the effect of improving the straightening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

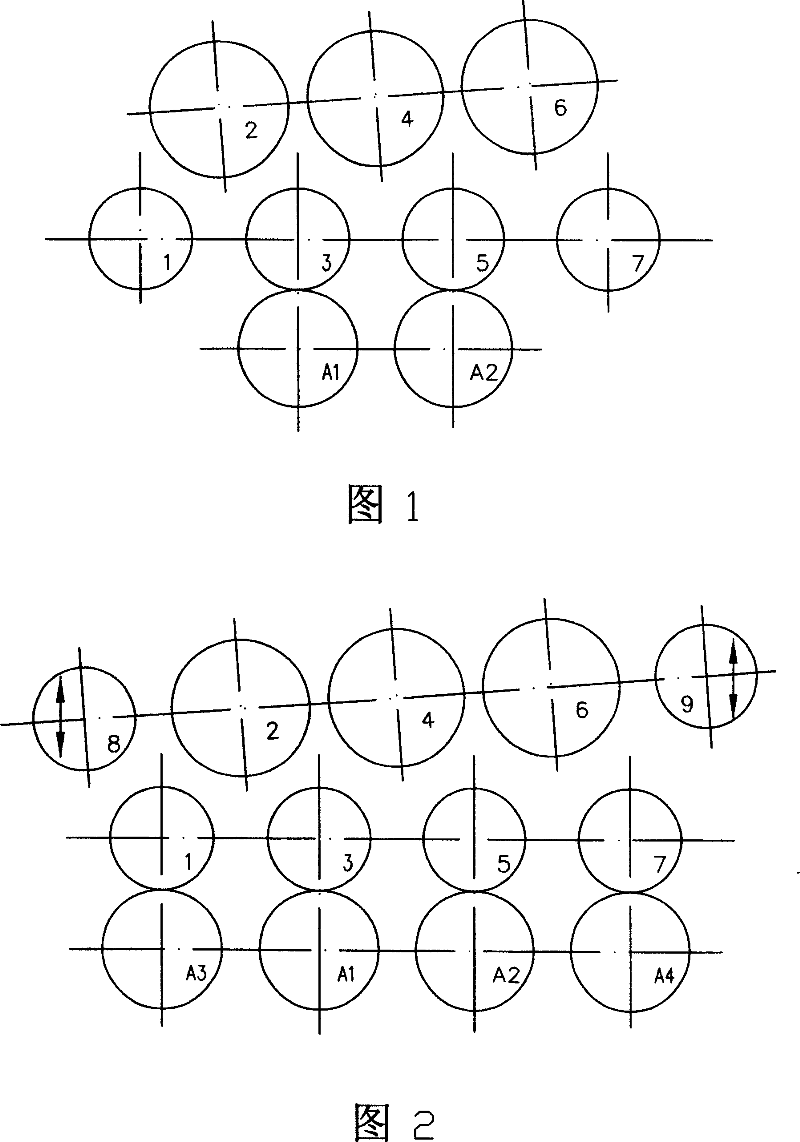

[0016] Fig. 1 is one of the embodiments of the present invention, a seven-roll plate leveling machine, in which 1, 2, 3, 4, 5, 6, and 7 are work rolls, and 2, 4, and 6 are movable row work rolls, without backup rolls Driven by the movable row of work rolls installed on the frame above it and the lifting screw of the bearing seat, the movable row of work rolls can be lifted or tilted along the inner guide plate of the frame, and 1, 3, 5, and 7 are fixed Row of work rolls, installed on the frame, A1, A2 are backup rolls of work rolls 3 and 5, installed on the lower beam or chassis between the two frames, and the plates are at the 2nd, 3rd, 4th, 5th, 6th rolls A total of five times of deformation, elastic deformation at the 6th roller of the discharge, elastoplastic deformation at the 2nd, 3rd, 4th, and 5th rollers, and the reduction decreases in turn, and the plate is downward at the 2nd and 4th rollers Bending, the plate bends upward at the 3rd and 5th rolls, the maximum reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com