Machine tool electric main shaft realizing supporting float by adopting hydrostatic bearing

A technology of hydrostatic bearings and electric spindles, applied in bearings, shafts and bearings, driving devices, etc., can solve the problems of increased difficulty in machining the spindle support hole, affecting the rotation accuracy of the spindle, spindle stiffness, and gaps in the radial direction, etc., to achieve Ideal precision and damping performance, reduced difficulty of machining and installation and debugging process, and the effect of absorbing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

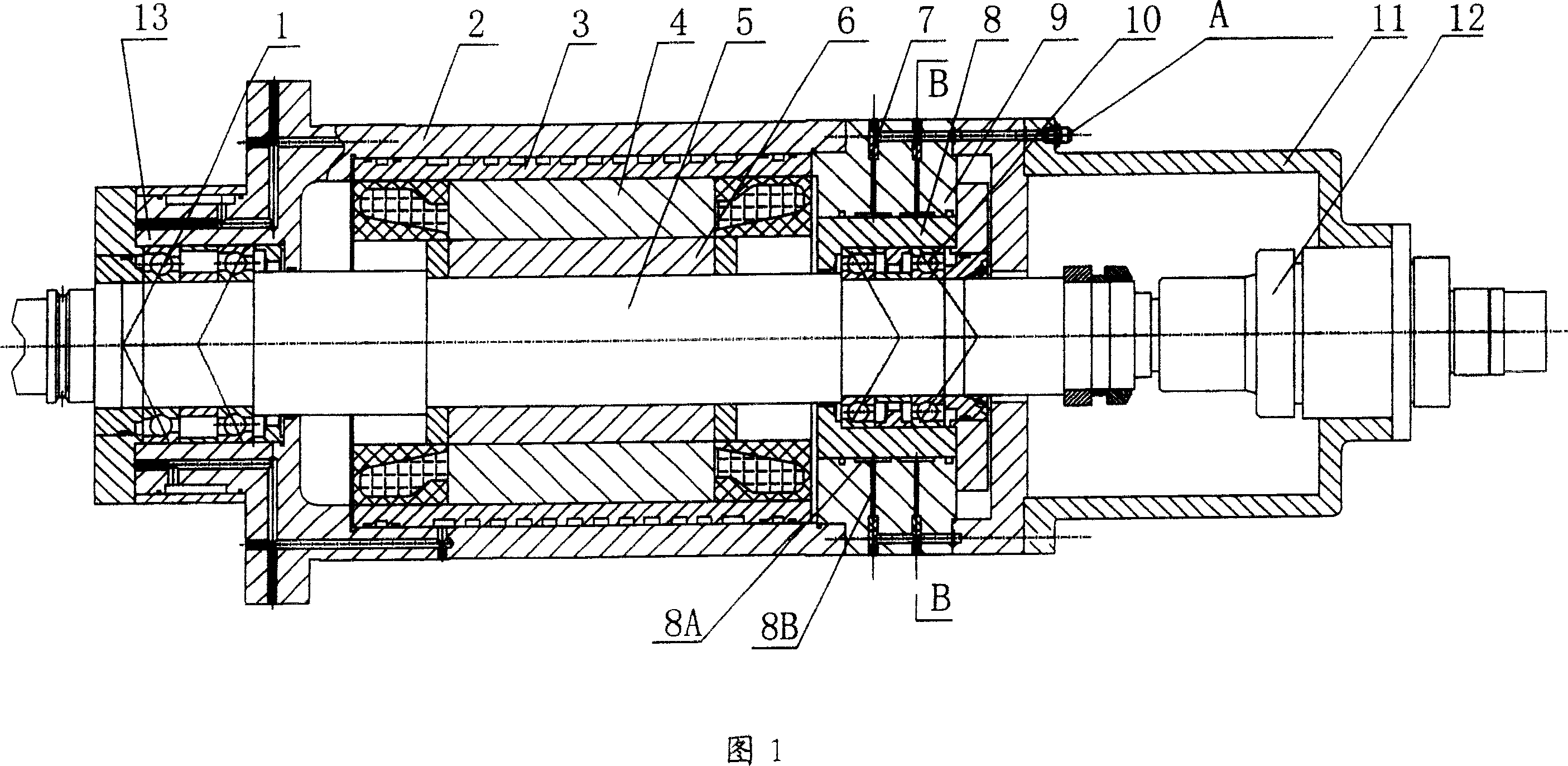

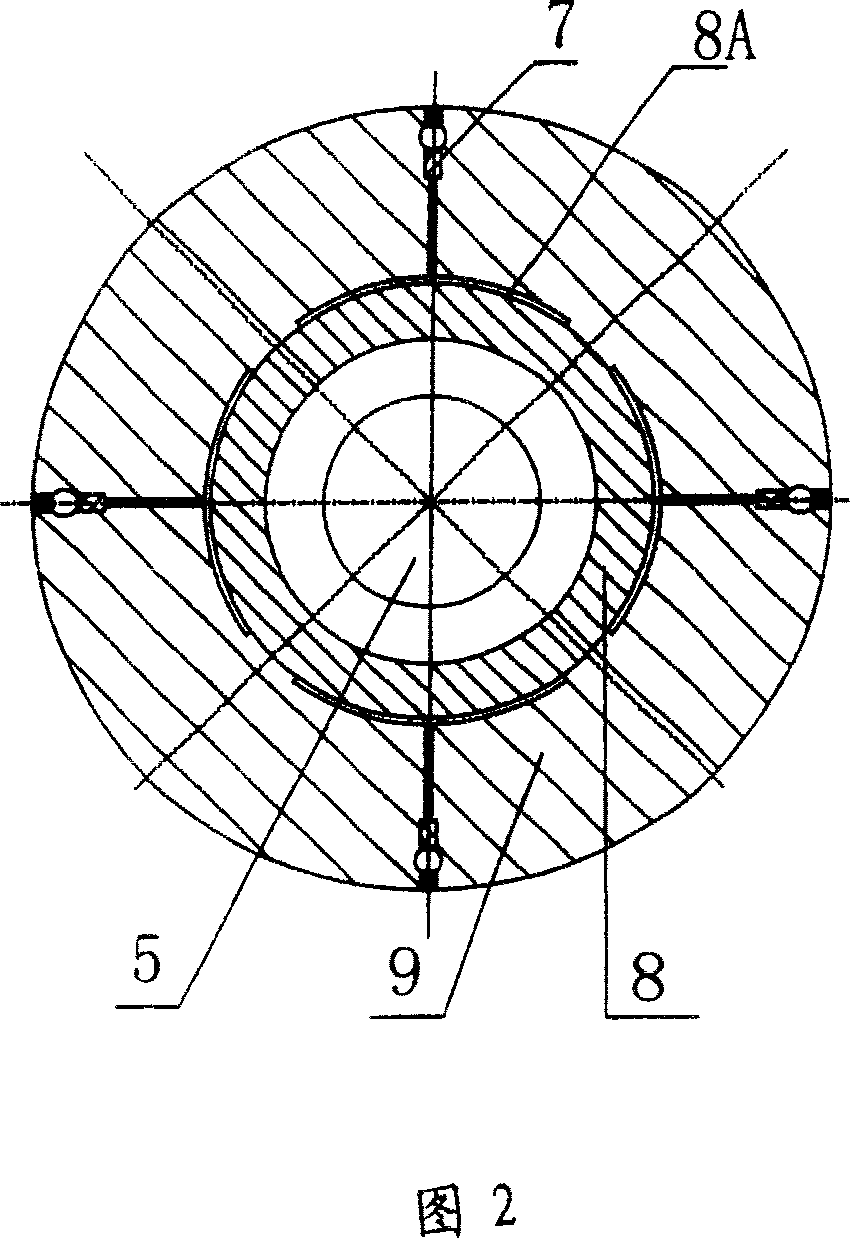

[0017] The structure diagram of the present invention is shown in Figures 1 and 2, including the main shaft front support (1), the main shaft (5), and the main shaft rear support (10). Both ends of the main shaft (5) are respectively supported on the main shaft front support (1) And the main shaft rear support (10), and the main shaft front support (1) is supported on the front support bearing seat (13), the main shaft rear support (10) is supported on the rear support bearing seat (9), and the main shaft rear support (10) A rear support floating sleeve (8) is also provided between the rear support bearing seat (9) and the main shaft rear support (10) is sleeved in the rear support floating sleeve (8), and the rear support floating sleeve (8) is sleeved on the rear support There are several oil chambers (8A) on the bearing seat (9), and on the inner wall of the rear supporting bearing seat (9) in contact with the rear supporting floating sleeve (8), the oil chamber (8A) passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com