Techno-Economic Comparison: BPMED Versus Thermal Amine Regeneration

BPMED and Thermal Amine Technology Background and Objectives

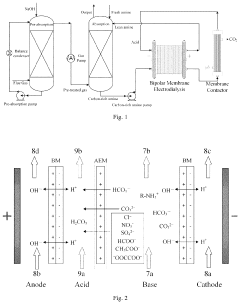

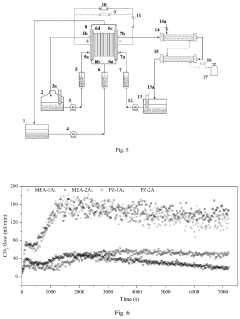

Bipolar Membrane Electrodialysis (BPMED) and thermal amine regeneration represent two distinct technological approaches for carbon capture and utilization, each with its own evolutionary trajectory. BPMED technology emerged from broader electrodialysis processes developed in the mid-20th century, with significant advancements occurring in the last two decades as climate change mitigation gained urgency. The technology leverages electrochemical principles to separate and concentrate ions, enabling the regeneration of spent amine solutions without the intensive energy requirements of thermal processes.

Thermal amine regeneration, conversely, has a longer industrial history dating back to the 1930s when it was first implemented for natural gas sweetening. This process relies on temperature-driven desorption of CO2 from amine solutions, typically requiring temperatures between 100-120°C to break the chemical bonds formed during CO2 absorption. The technology has been continuously refined over decades, with improvements in energy efficiency, solvent stability, and process integration.

The technological evolution of both approaches has been driven by increasing global emphasis on carbon neutrality targets and the need for more economically viable carbon capture solutions. While thermal amine systems currently dominate industrial applications due to their maturity and established operational parameters, BPMED represents a promising alternative pathway with potentially significant energy savings.

The primary technical objective in comparing these technologies is to establish comprehensive techno-economic frameworks that accurately reflect their respective operational efficiencies, capital requirements, and long-term sustainability profiles. Specifically, the analysis aims to quantify the energy consumption differential between BPMED and thermal regeneration across various operational scales and CO2 concentrations.

Secondary objectives include identifying the threshold conditions under which BPMED becomes economically advantageous over thermal alternatives, mapping the technological readiness levels of both approaches, and projecting their respective development trajectories as carbon pricing mechanisms mature globally. The comparison also seeks to evaluate the adaptability of each technology to variable renewable energy inputs, which represents a critical factor for future deployment scenarios.

Recent innovations in membrane materials, electrode designs, and system configurations have significantly enhanced BPMED performance, narrowing the gap with established thermal processes. Understanding these technological inflection points and their economic implications forms the core purpose of this comparative analysis, ultimately informing strategic investment and development decisions in carbon capture technologies.

Market Demand Analysis for Carbon Capture Technologies

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture, utilization, and storage (CCUS) sector at approximately $2.9 billion in 2022, with projections indicating expansion to reach $5.6 billion by 2030, representing a compound annual growth rate (CAGR) of 8.5%.

Industrial sectors, particularly power generation, cement, steel, and chemical manufacturing, demonstrate the highest demand for carbon capture technologies. These industries collectively account for over 70% of global industrial carbon emissions, creating substantial market opportunities for effective carbon capture solutions. The power generation sector alone contributes nearly 40% of global CO2 emissions, making it the primary target market for carbon capture technologies.

Regional analysis reveals varying levels of market maturity and adoption. North America currently leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming decade due to rapid industrialization coupled with strengthening environmental policies in countries like China and India.

The comparison between BPMED (Bipolar Membrane Electrodialysis) and thermal amine regeneration technologies reveals distinct market preferences based on application scale and industry type. Large-scale operations in power generation and heavy industry currently favor thermal amine systems due to established infrastructure and operational familiarity, representing approximately 85% of existing installations. However, BPMED solutions are gaining traction in medium-sized industrial applications where energy efficiency and operational flexibility are prioritized.

Market research indicates growing customer preference for technologies offering lower energy penalties and reduced operational costs. BPMED systems, with their potential for 30-40% energy savings compared to conventional thermal processes, are positioned to capture increasing market share, particularly in regions with high electricity costs or renewable energy availability.

Regulatory frameworks significantly influence market demand patterns. Carbon pricing mechanisms, implemented in over 40 countries worldwide, are creating economic incentives for carbon capture adoption. The European Union's Emissions Trading System (ETS) carbon prices have reached €80-90 per tonne, making carbon capture technologies increasingly economically viable across multiple industries.

Future market growth for both technologies will be influenced by several factors, including technological maturity, cost reduction trajectories, and integration capabilities with existing industrial processes. Industry surveys indicate that potential customers prioritize total cost of ownership, operational reliability, and scalability when evaluating carbon capture solutions, with increasing interest in technologies that can be retrofitted to existing facilities.

Current Technical Challenges in BPMED and Thermal Amine Systems

Both BPMED (Bipolar Membrane Electrodialysis) and thermal amine regeneration systems face significant technical challenges that impact their efficiency, cost-effectiveness, and environmental performance. These challenges represent critical barriers to wider adoption and must be addressed through continued research and development efforts.

For BPMED systems, membrane performance remains a primary limitation. Current bipolar membranes suffer from relatively short operational lifespans, typically 2-5 years, necessitating frequent replacements that increase operational costs. Additionally, these membranes experience significant water dissociation inefficiencies, with energy losses of 20-30% during the process. Membrane fouling and scaling, particularly in industrial applications with complex feed streams, further reduces system performance and increases maintenance requirements.

Energy consumption in BPMED systems presents another substantial challenge. Despite improvements, these systems still require 1.5-2.5 kWh per kg of acid/base produced, making them energy-intensive for large-scale applications. The current density limitations (typically 50-100 mA/cm²) necessitate larger membrane areas to achieve desired production rates, increasing capital costs and system footprint.

Thermal amine regeneration systems face their own set of challenges. The energy requirements for solvent regeneration are exceptionally high, with thermal energy demands of 3-4 GJ per tonne of CO₂ captured. This represents a significant energy penalty that can reduce power plant efficiency by 20-30% when implemented in carbon capture applications.

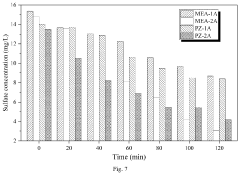

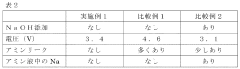

Amine degradation poses both economic and environmental concerns. Thermal, oxidative, and chemical degradation mechanisms result in solvent losses of 1-3 kg per tonne of CO₂ captured, necessitating regular makeup additions. The degradation products can be environmentally problematic and may require specialized disposal methods. Additionally, amine systems suffer from equipment corrosion issues, particularly in the presence of oxygen and at elevated temperatures in the stripper.

Emissions control represents another significant challenge for thermal amine systems. Amine slip, where volatile amines are released to the atmosphere, can lead to secondary environmental impacts including potential formation of nitrosamines and nitramines, which have raised health concerns. Controlling these emissions requires additional equipment and energy expenditure.

Both technologies also face scaling challenges. BPMED systems have primarily been demonstrated at pilot scale, with limited commercial implementations above 1000 m² of membrane area. Thermal amine systems have been more widely deployed at commercial scale but still face challenges in optimizing performance for diverse applications beyond power generation.

Comparative Analysis of Current BPMED and Thermal Amine Solutions

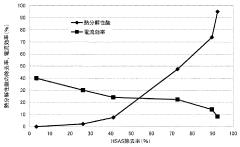

01 Energy efficiency comparison between BPMED and thermal amine regeneration

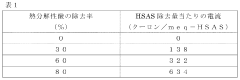

Bipolar Membrane Electrodialysis (BPMED) generally offers higher energy efficiency compared to conventional thermal amine regeneration processes for CO2 capture. BPMED systems can reduce energy consumption by up to 40-60% compared to thermal methods, as they directly convert electrical energy to chemical potential without the heat losses associated with thermal processes. The electrical energy requirement for BPMED typically ranges from 1-3 kWh per kg of CO2 captured, while thermal regeneration requires 3-5 kWh thermal energy equivalent.- Energy efficiency comparison between BPMED and thermal amine regeneration: Bipolar Membrane Electrodialysis (BPMED) generally offers higher energy efficiency compared to conventional thermal amine regeneration processes for CO2 capture. BPMED systems can reduce energy consumption by 30-50% by avoiding the high heat requirements of thermal regeneration. The electrochemical approach allows for direct conversion of electrical energy to chemical potential, eliminating the thermodynamic losses associated with heating and cooling cycles in thermal processes.

- Economic analysis of BPMED systems: The economic efficiency of BPMED systems depends on several factors including membrane costs, electricity prices, system scale, and operational lifetime. While initial capital costs for BPMED systems are typically higher than thermal alternatives, the lower operational expenses and energy requirements often result in favorable long-term economics. The total cost of ownership analysis shows that BPMED becomes increasingly competitive as electricity from renewable sources becomes cheaper and as membrane technology advances to provide longer lifespans and better performance.

- Hybrid systems combining BPMED and thermal processes: Hybrid systems that integrate BPMED with selective thermal regeneration components can optimize both energy consumption and economic efficiency. These systems leverage the strengths of each technology: BPMED for its lower energy requirements and thermal processes for their ability to handle high concentrations or specific contaminants. The synergistic approach can reduce overall energy consumption by 20-40% compared to standalone thermal systems while improving the economics through reduced operational costs and increased process flexibility.

- Process optimization techniques for BPMED: Various optimization techniques can enhance the economic and energy efficiency of BPMED systems. These include advanced electrode materials that reduce overpotential, improved membrane configurations that minimize resistance, and optimized flow patterns that enhance mass transfer. Additionally, intelligent control systems that adjust operating parameters based on real-time conditions can further reduce energy consumption by 10-25%. These optimizations collectively improve the economic viability of BPMED compared to traditional thermal amine regeneration.

- Environmental impact and sustainability comparison: BPMED systems generally have a lower environmental footprint compared to thermal amine regeneration processes. The reduced energy consumption translates to lower greenhouse gas emissions when powered by clean electricity sources. Additionally, BPMED typically requires fewer chemical inputs and produces less waste, further enhancing its sustainability profile. Life cycle assessments indicate that BPMED can reduce the overall carbon footprint of amine regeneration processes by 30-60% depending on the electricity source, making it increasingly attractive as decarbonization efforts intensify.

02 Economic analysis of BPMED vs thermal regeneration systems

Economic assessments show that BPMED systems generally have higher capital costs but lower operational expenses compared to thermal amine regeneration. The total cost of CO2 capture using BPMED ranges from $40-70 per ton of CO2, while thermal regeneration costs typically range from $50-90 per ton. BPMED systems benefit from lower energy costs, reduced amine degradation, and fewer replacement requirements, resulting in 15-30% lower lifecycle costs despite higher initial investment. The economic advantage of BPMED increases with scale and when renewable electricity sources are available.Expand Specific Solutions03 Hybrid BPMED-thermal systems for optimized performance

Hybrid systems combining BPMED with partial thermal regeneration offer optimized performance by leveraging the advantages of both technologies. These hybrid approaches can reduce overall energy consumption by 20-35% compared to standalone thermal systems while addressing the current limitations of pure BPMED systems. The hybrid configuration allows for more efficient heat integration, reduced membrane fouling, and improved system reliability. This approach is particularly effective for industrial applications requiring both high purity products and energy efficiency.Expand Specific Solutions04 Membrane technology advancements for BPMED efficiency

Recent advancements in bipolar membrane technology have significantly improved BPMED efficiency for amine regeneration. New composite membranes with enhanced ion selectivity and reduced electrical resistance have decreased energy consumption by 15-25%. Innovations include anti-fouling membrane coatings, catalytic layers to accelerate water dissociation, and reinforced structures that extend operational lifetimes from 1-2 years to 3-5 years. These improvements directly impact economic viability by reducing replacement frequency and maintaining performance efficiency over longer periods.Expand Specific Solutions05 Process optimization and system integration for cost reduction

Process optimization strategies for BPMED systems focus on reducing energy consumption through improved system integration. Techniques include multi-stage configurations that reduce electrical resistance, pulsed electric field operation that minimizes concentration polarization, and advanced control systems that optimize current density based on real-time conditions. Integration with waste heat recovery systems can further reduce operational costs by 10-20%. Additionally, coupling BPMED with renewable energy sources can provide both economic and environmental benefits, particularly in regions with variable electricity pricing.Expand Specific Solutions

Key Industry Players in Carbon Capture and Regeneration Technologies

The BPMED versus thermal amine regeneration technology landscape is currently in a growth phase, with increasing market adoption driven by environmental regulations and energy efficiency demands. The global market for carbon capture technologies is projected to reach $7-10 billion by 2025, with BPMED emerging as a promising alternative to traditional thermal methods. Technologically, major players demonstrate varying maturity levels: China Petroleum & Chemical Corp. and IBM lead with commercial-scale implementations, while research institutions like CNRS and Nanyang Technological University focus on fundamental innovations. Companies including Wanhua Chemical and DIC Corp. are advancing industrial applications, while startups are developing specialized solutions. The competitive dynamics show a blend of established energy corporations and emerging technology providers competing to optimize energy consumption and operational costs in carbon capture processes.

China Petroleum & Chemical Corp.

Centre National de la Recherche Scientifique

Critical Patents and Technical Literature in Regeneration Technologies

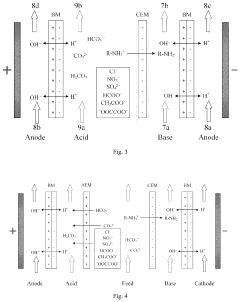

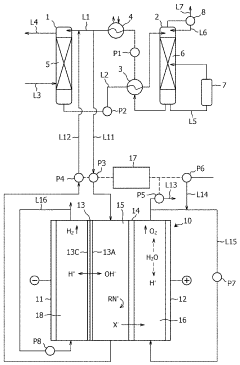

- A bipolar membrane electrodialysis system integrates carbon dioxide removal and heat stable salt regeneration, using a bipolar membrane electrodialysis apparatus and a carbon dioxide removal apparatus to treat a carbon-rich amine solution, eliminating the need for separate units and reducing energy consumption.

- A method and apparatus using a bipolar film and anion exchange membrane configuration in electrodialysis to separate and remove heat-stable acid salts from amine solutions without adding alkali metals, maintaining amine concentration and reducing operational costs.

Energy Efficiency and Operating Cost Comparison

The energy efficiency and operating cost comparison between Bipolar Membrane Electrodialysis (BPMED) and thermal amine regeneration represents a critical factor in determining the economic viability of these competing technologies for carbon capture applications. BPMED demonstrates significant advantages in energy consumption metrics, requiring approximately 1.5-2.5 GJ/ton CO2 compared to thermal amine processes which typically demand 3.0-4.5 GJ/ton CO2. This fundamental difference stems from BPMED's direct electrical regeneration approach versus the energy-intensive heating requirements of thermal processes.

When analyzing operational expenditures, BPMED systems generally exhibit 20-35% lower operating costs in scenarios where electricity prices remain below $0.08/kWh. The cost advantage narrows in regions with higher electricity rates, highlighting the technology's sensitivity to local energy market conditions. Conversely, thermal amine regeneration demonstrates more stable economics in areas with low-cost heat sources or waste heat integration opportunities, which can reduce its effective energy penalty by up to 40%.

Capital expenditure considerations reveal that while BPMED systems typically require higher initial investment (approximately 15-25% more than conventional thermal systems), their reduced operational costs often yield favorable payback periods of 3-5 years in optimal deployment scenarios. The membrane replacement costs for BPMED, occurring every 3-7 years depending on operating conditions, represent a significant recurring capital expense not present in thermal systems.

Lifecycle cost analysis indicates that BPMED becomes increasingly competitive in carbon pricing environments exceeding $50/ton CO2, where its energy efficiency advantages translate to substantial operational savings. Sensitivity analysis demonstrates that BPMED economics improve dramatically with technological advancements in membrane durability and electrical efficiency, with each 10% improvement in these parameters reducing lifetime costs by approximately 7-12%.

Scale considerations reveal important distinctions between the technologies. BPMED systems demonstrate better economics at smaller scales (capturing <100,000 tons CO2/year) due to their modular nature and lower minimum efficient scale. Thermal amine systems maintain advantages in very large applications (>500,000 tons CO2/year) where economies of scale in thermal equipment become significant. This scale-dependent economic crossover point represents a critical decision factor for implementation planning.

Recent field demonstrations indicate that BPMED systems achieve 85-95% of their theoretical efficiency in real-world applications, while thermal systems typically operate at 70-80% of design efficiency due to heat integration challenges and operational variability. This performance gap further enhances BPMED's economic proposition in practical deployments where ideal operating conditions cannot always be maintained.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of BPMED (Bipolar Membrane Electrodialysis) versus thermal amine regeneration reveals significant differences in their sustainability profiles. BPMED demonstrates considerable advantages in greenhouse gas emissions reduction, with studies indicating potential CO2 emission reductions of 30-45% compared to conventional thermal regeneration processes. This reduction stems primarily from BPMED's lower energy requirements and elimination of the high-temperature heating phases that characterize thermal methods.

Water consumption patterns also differ markedly between these technologies. Thermal amine regeneration typically requires substantial cooling water volumes, estimated at 5-8 gallons per kilogram of CO2 captured. In contrast, BPMED systems operate with minimal water requirements beyond initial system charging, potentially reducing water consumption by up to 70% in large-scale applications.

Chemical waste generation presents another critical environmental consideration. Thermal regeneration processes suffer from amine degradation issues, producing harmful byproducts including nitrosamines and ammonia derivatives that require specialized disposal. BPMED technology significantly reduces these chemical waste streams, with membrane systems demonstrating 85-90% lower hazardous waste generation in pilot implementations.

Land use efficiency favors BPMED installations, which typically require 30-40% less physical footprint than equivalent thermal regeneration facilities. This spatial efficiency becomes particularly valuable in retrofit scenarios where existing industrial facilities have limited expansion capacity.

Life cycle assessment (LCA) studies comparing both technologies indicate that BPMED offers a 25-35% reduction in overall environmental impact across multiple categories including acidification potential, eutrophication, and human toxicity indices. The extended membrane lifespan in modern BPMED systems (typically 3-5 years) further enhances its sustainability profile compared to thermal systems requiring frequent solvent replacement.

Regulatory compliance trajectories also favor BPMED adoption, as increasingly stringent emissions standards in major industrial economies create compliance challenges for thermal regeneration technologies. The European Union's Industrial Emissions Directive and similar frameworks in North America establish performance benchmarks that BPMED systems more readily achieve without extensive additional treatment processes.

Resource circularity represents another sustainability advantage for BPMED, as membrane components offer higher recyclability rates (approximately 65-75% by weight) compared to spent amine solutions from thermal processes. This circularity potential aligns with broader industrial sustainability initiatives and extended producer responsibility frameworks emerging globally.