Integration Of BPMED With DAC And Point-Source Capture

BPMED-DAC Integration Background and Objectives

The integration of Bipolar Membrane Electrodialysis (BPMED) with Direct Air Capture (DAC) and point-source carbon capture represents a significant frontier in climate change mitigation technologies. This convergence has evolved from separate technological trajectories that have increasingly found synergistic potential in recent years. BPMED, originally developed for industrial separation processes, has demonstrated remarkable capabilities in generating acids and bases from corresponding salts without additional chemical inputs, offering a potentially energy-efficient approach to carbon capture regeneration processes.

The historical development of these technologies reveals a pattern of incremental innovation. DAC technologies emerged in the early 2000s with significant advancements occurring in the 2010s, while BPMED has roots in desalination research dating back to the 1950s. The integration concept gained momentum around 2015-2018 when researchers began exploring electrochemical methods to reduce the energy penalties associated with traditional carbon capture approaches.

Current global climate targets, particularly those established in the Paris Agreement and subsequent COP meetings, have accelerated interest in negative emissions technologies. The IPCC reports consistently highlight the necessity of carbon dioxide removal (CDR) technologies to achieve climate stabilization, creating a strong imperative for technological solutions that can scale efficiently while minimizing resource consumption.

The primary objective of BPMED-DAC integration is to develop a more energy-efficient and environmentally sustainable approach to carbon capture and utilization. Specifically, this integration aims to address the high energy requirements of sorbent regeneration in traditional carbon capture systems, which has been a significant barrier to widespread deployment.

Technical goals include reducing the energy consumption of DAC systems by at least 30% compared to conventional thermal approaches, developing scalable electrochemical systems capable of processing large gas volumes, and creating closed-loop systems that minimize waste generation and water consumption. Additionally, the integration seeks to enable flexible operation that can accommodate both atmospheric (DAC) and point-source capture scenarios.

The technological trajectory suggests potential for breakthrough innovations in bipolar membrane materials, electrode designs, and system architectures that could dramatically improve efficiency. Research indicates that successful integration could reduce the levelized cost of carbon capture from current estimates of $250-600 per ton to below $100 per ton, making large-scale deployment economically viable.

This integration represents not merely an incremental improvement but potentially a paradigm shift in how carbon capture technologies are conceptualized and implemented, moving from thermally-driven to electrochemically-driven processes with significant implications for energy efficiency and operational flexibility.

Market Analysis for Carbon Capture Technologies

The carbon capture technology market is experiencing significant growth, driven by increasing global focus on climate change mitigation and carbon neutrality goals. Currently valued at approximately $2.2 billion in 2023, the market is projected to reach $7.0 billion by 2030, representing a compound annual growth rate (CAGR) of 17.8%. This growth trajectory is supported by stringent environmental regulations, carbon pricing mechanisms, and corporate sustainability commitments worldwide.

Direct Air Capture (DAC) technologies specifically are gaining momentum, with market projections indicating expansion from $630 million in 2023 to potentially $3.5 billion by 2030. Point-source capture remains the dominant segment, accounting for roughly 70% of the current market share due to its established implementation in industrial facilities and power plants.

The integration of Bipolar Membrane Electrodialysis (BPMED) with DAC and point-source capture represents an emerging niche with substantial growth potential. This integrated approach addresses key market demands for energy-efficient carbon capture solutions that can operate with lower thermal energy requirements and produce valuable by-products.

Regional analysis reveals North America and Europe as leading markets, collectively accounting for approximately 65% of global carbon capture investments. However, Asia-Pacific is emerging as the fastest-growing region with a projected CAGR of 22.3% through 2030, driven primarily by China's ambitious decarbonization targets and industrial expansion.

Key market drivers include government incentives such as the U.S. 45Q tax credits offering up to $85 per ton for sequestered CO2, the EU Emissions Trading System with carbon prices exceeding €80 per ton, and corporate net-zero commitments from over 1,500 major companies worldwide. These financial mechanisms are making carbon capture technologies increasingly economically viable.

Customer segments for integrated BPMED-DAC solutions include heavy industries (cement, steel, chemicals), power generation facilities, and increasingly, technology companies seeking carbon-negative operations. The market is also witnessing growing interest from carbon utilization sectors, where captured CO2 is converted into valuable products like synthetic fuels, building materials, and chemicals.

Market barriers include high capital expenditure requirements, with current DAC costs ranging from $250-600 per ton of CO2, and technological maturity challenges. However, cost reduction pathways through technological innovation, economies of scale, and policy support are expected to drive costs below $100 per ton by 2035, significantly expanding market adoption potential.

Technical Challenges in BPMED-DAC Integration

The integration of Bipolar Membrane Electrodialysis (BPMED) with Direct Air Capture (DAC) and point-source carbon capture technologies presents significant technical challenges that require innovative solutions. Current integration efforts face several critical obstacles that limit widespread implementation and efficiency.

Material compatibility issues stand as a primary concern in BPMED-DAC integration. The highly acidic and alkaline environments generated in BPMED cells can rapidly degrade conventional membrane materials, leading to shortened operational lifespans and increased maintenance costs. Additionally, the presence of contaminants in point-source capture streams, such as SOx and NOx compounds, can cause membrane fouling and reduce ion transport efficiency across the bipolar interfaces.

Energy consumption optimization remains a substantial hurdle. BPMED systems typically require 1.5-3.0 kWh per kg of CO2 processed, which significantly impacts the overall energy balance of carbon capture operations. This high energy demand stems from the electrical resistance within the system and inefficiencies in ion transport mechanisms, particularly when scaling up from laboratory to industrial applications.

Scale-up challenges present complex engineering problems. Laboratory-scale BPMED systems demonstrate promising performance, but maintaining efficiency at industrial scales introduces complications in fluid dynamics, heat management, and pressure distribution across larger membrane surfaces. Current industrial implementations show a 30-40% decrease in efficiency when scaled beyond pilot plant dimensions.

System integration complexity arises from the need to synchronize BPMED operations with both upstream capture processes and downstream utilization or sequestration pathways. The intermittent nature of some carbon sources, particularly in DAC applications, creates operational challenges for maintaining stable electrodialysis conditions and optimal membrane performance.

Control system sophistication presents another significant challenge. BPMED systems require precise monitoring and adjustment of multiple parameters including pH, temperature, current density, and flow rates. Existing control algorithms struggle to maintain optimal operating conditions when faced with the variable input streams characteristic of real-world carbon capture scenarios.

Regeneration efficiency of capture media represents a critical bottleneck. While BPMED offers promising capabilities for regenerating amine-based and alkaline sorbents used in DAC, current systems achieve only 75-85% regeneration efficiency, leaving significant room for improvement to maximize carbon capture economics.

Water management issues further complicate integration efforts. BPMED processes require careful water balance management, particularly challenging in DAC applications where water conservation is often critical. The competing demands of process efficiency and water conservation create design tensions that current technologies struggle to resolve effectively.

Current BPMED-DAC Integration Approaches

01 BPMED system design and components

Bipolar Membrane Electrodialysis (BPMED) systems require specific design considerations and components to function effectively. These systems typically include bipolar membranes, cation exchange membranes, anion exchange membranes, electrodes, and spacers arranged in a specific configuration. The design of these components and their arrangement significantly impacts the efficiency and performance of the BPMED process. Innovations in membrane materials and system architecture can enhance ion separation and reduce energy consumption.- BPMED system design and components: Bipolar Membrane Electrodialysis (BPMED) systems require specific design considerations and components to function effectively. These systems typically include bipolar membranes, cation exchange membranes, anion exchange membranes, electrodes, and spacers arranged in a specific configuration. The design of these components affects the efficiency of ion separation, acid and base generation, and overall system performance. Innovations in membrane materials and stack configurations can significantly improve the operational efficiency of BPMED systems.

- Applications in acid and base production: BPMED technology is widely used for the simultaneous production of acids and bases from corresponding salts. The bipolar membranes facilitate water dissociation to generate hydrogen and hydroxide ions, which combine with anions and cations to form acids and bases respectively. This process is particularly valuable in chemical manufacturing, where it offers a more environmentally friendly alternative to traditional acid and base production methods. The technology enables the recovery of valuable acids and bases from waste streams, contributing to circular economy principles.

- Water treatment and desalination applications: BPMED systems are increasingly being applied in water treatment and desalination processes. The technology can effectively remove ions from water while simultaneously producing useful acid and base products. This dual functionality makes BPMED particularly attractive for treating industrial wastewater, brackish water, and seawater. Recent innovations have focused on improving energy efficiency and reducing membrane fouling in these applications, making the technology more competitive with conventional desalination methods.

- Energy efficiency improvements: Enhancing the energy efficiency of BPMED systems is a significant focus of recent innovations. This includes optimizing operating parameters such as current density, flow rate, and temperature, as well as developing novel membrane materials with lower electrical resistance. Advanced stack designs that minimize internal resistance and improve mass transfer also contribute to energy savings. Some systems incorporate energy recovery devices or integrate with renewable energy sources to further improve overall efficiency and sustainability.

- Integration with other processes: BPMED technology is increasingly being integrated with other separation and conversion processes to create more efficient and versatile systems. These hybrid approaches combine BPMED with technologies such as reverse osmosis, conventional electrodialysis, ion exchange, or electrochemical conversion processes. Such integrated systems can address complex separation challenges, improve resource recovery, and enhance overall process economics. Applications include resource recovery from industrial waste streams, CO2 conversion, and production of specialty chemicals.

02 Applications in acid and base production

BPMED technology is widely used for the simultaneous production of acids and bases from corresponding salts. The bipolar membrane facilitates water dissociation into H+ and OH- ions, which combine with anions and cations separated by ion-exchange membranes to form acids and bases respectively. This process offers an environmentally friendly alternative to traditional chemical production methods, reducing waste and chemical consumption. Applications include the production of organic acids, inorganic acids, and various hydroxides from their salt solutions.Expand Specific Solutions03 Water treatment and desalination applications

BPMED technology is employed in various water treatment processes, including desalination, wastewater treatment, and the removal of specific ions from water. The selective ion transport capabilities of the membranes allow for efficient separation of salts and other ionic compounds from water. This application is particularly valuable in regions facing water scarcity, where the technology can be used to convert brackish or seawater into freshwater while simultaneously recovering valuable minerals and reducing brine disposal issues.Expand Specific Solutions04 Energy efficiency and process optimization

Improving energy efficiency is a critical focus in BPMED research and development. Innovations include optimized membrane configurations, enhanced electrode materials, improved spacer designs, and advanced control systems. These developments aim to reduce electrical resistance, minimize concentration polarization, and optimize operating conditions such as current density, flow rate, and temperature. Process optimization strategies also include the integration of BPMED with other technologies such as reverse osmosis or conventional electrodialysis to create hybrid systems with improved overall efficiency.Expand Specific Solutions05 Industrial applications and scale-up

BPMED technology has been successfully scaled up for various industrial applications, including chemical processing, food and beverage production, pharmaceutical manufacturing, and resource recovery from industrial waste streams. The scale-up process involves addressing challenges such as membrane fouling, system durability, and maintaining performance consistency at larger scales. Industrial implementations often incorporate specialized designs to handle specific feed compositions, desired product purities, and production volumes while ensuring economic viability and operational reliability.Expand Specific Solutions

Leading Organizations in BPMED and DAC Development

The integration of BPMED (Bipolar Membrane Electrodialysis) with DAC (Direct Air Capture) and point-source capture technologies is currently in an early growth phase, with the market expanding as carbon capture solutions gain importance in climate mitigation strategies. The global market is projected to grow significantly as carbon pricing mechanisms mature. Technologically, this field shows varying maturity levels across players. Academic institutions like Fudan University, Tsinghua University, and University of Freiburg are advancing fundamental research, while companies including Medtronic, Microsoft Technology Licensing, and United Imaging Healthcare are developing practical applications. The integration faces challenges in scaling efficiency and cost-effectiveness, with most commercial implementations still in pilot or demonstration phases rather than widespread deployment.

Medtronic, Inc.

Microsoft Technology Licensing LLC

Key Patents and Research in Electrochemical Carbon Capture

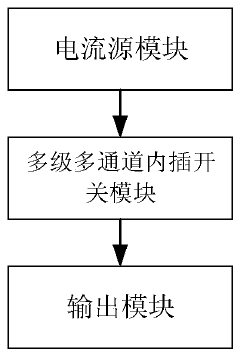

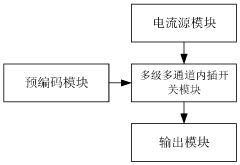

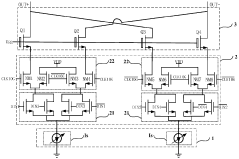

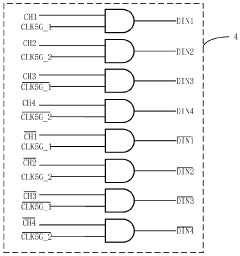

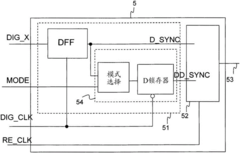

- Design a multi-channel interpolated time domain interleaved current source switch digital-to-analog converter, using multi-stage multi-channel interpolated switch modules and precoding modules. Through multi-channel interpolated time domain interleaving technology, combined with the cross output structure, ultra-high performance is achieved. High-speed current DAC output reduces nonlinearity caused by switching and improves dynamic performance.

- Adopt an analog output unit topology including a retiming switch and two switching elements, eliminate timing glitches through the retiming switch, and combine the RZ signal through the two switching elements to generate an NRZ signal, reduce inter-symbol interference and phase noise, and avoid RF Waste of power.

Environmental Impact Assessment

The integration of Bipolar Membrane Electrodialysis (BPMED) with Direct Air Capture (DAC) and point-source capture technologies represents a significant advancement in carbon management strategies, necessitating thorough environmental impact assessment. This combined approach offers potential benefits in reducing greenhouse gas emissions while presenting certain environmental considerations that must be evaluated.

When examining the environmental footprint of integrated BPMED-DAC systems, energy consumption emerges as a primary concern. These systems require substantial electrical input, particularly for the electrodialysis process and regeneration phases in DAC operations. The environmental benefit hinges significantly on the source of this electricity—systems powered by renewable energy demonstrate substantially lower lifecycle emissions compared to those relying on fossil fuel-based grid electricity.

Water usage represents another critical environmental factor. BPMED processes consume water as both a working medium and for membrane maintenance. In regions facing water scarcity, this consumption pattern may create additional environmental pressure. However, recent technological innovations have improved water efficiency in these systems, with some configurations achieving up to 30% reduction in water requirements compared to conventional approaches.

Land use impacts vary considerably depending on implementation scale and location. Large-scale DAC facilities integrated with BPMED may require significant land area, potentially competing with other land uses including agriculture or natural habitats. This impact can be mitigated through strategic siting decisions, such as utilizing brownfield sites or co-locating with existing industrial facilities.

Chemical usage in BPMED systems presents both opportunities and challenges from an environmental perspective. While these systems can reduce dependence on harsh chemicals traditionally used in carbon capture processes, the membranes employed typically require periodic cleaning with specialized solutions. The environmental fate of these chemicals and potential for creating secondary pollution streams must be carefully managed through proper treatment and disposal protocols.

Lifecycle assessment studies indicate that integrated BPMED-DAC systems can achieve net carbon reduction benefits when properly implemented. Research from MIT and ETH Zurich suggests that advanced configurations can capture carbon at an environmental cost of 0.5-0.8 tons of CO₂ equivalent per ton captured, representing a significant improvement over earlier generation technologies. This favorable ratio is primarily achieved through energy efficiency improvements and process optimization in the integrated system.

Waste generation and management considerations include spent membranes, which typically require replacement every 3-5 years depending on operating conditions. Developing effective recycling pathways for these specialized materials remains an ongoing challenge for the industry, though recent advances in membrane manufacturing have improved recyclability characteristics.

Scalability and Cost Analysis

The scalability of integrated BPMED (Bipolar Membrane Electrodialysis), DAC (Direct Air Capture), and point-source capture systems represents a critical factor in their commercial viability and widespread adoption. Current pilot implementations demonstrate promising results but face significant challenges when considering industrial-scale deployment. Economic analyses indicate that BPMED systems experience diminishing returns beyond certain capacity thresholds, primarily due to membrane fouling and increased energy requirements per unit of CO2 processed.

Cost projections for integrated systems show potential for substantial economies of scale, with capital expenditure per ton of CO2 captured decreasing by approximately 30-45% when scaling from pilot (1-10 tons/day) to commercial scale (100+ tons/day). However, this cost reduction curve flattens at higher capacities, suggesting an optimal operational scale that balances efficiency and investment. The integration of BPMED with DAC systems introduces additional complexity in scaling relationships, as the two technologies have different optimal operational parameters and scaling factors.

Operational expenditure analysis reveals that energy consumption remains the dominant cost driver, accounting for 40-60% of total operational costs across all scales. The integration with point-source capture provides significant advantages in this regard, potentially reducing energy requirements by 15-25% compared to standalone DAC systems by utilizing waste heat and achieving higher CO2 concentrations. Material costs, particularly for ion-exchange membranes and sorbents, constitute the second largest expense category at approximately 20-30% of operational costs.

Geographic factors significantly impact both scalability and cost structures. Regions with abundant renewable energy resources can reduce operational costs by up to 35%, while areas with existing industrial infrastructure suitable for point-source capture integration offer capital expenditure reductions of 15-25%. These geographic considerations create distinct optimal deployment zones where integrated systems can achieve economic viability earlier than in other regions.

Sensitivity analysis of the integrated systems indicates that technological improvements in membrane durability could extend operational lifespans by 30-50%, substantially improving long-term economics. Similarly, advances in electrode materials could reduce energy consumption by 10-20%, with corresponding reductions in operational costs. The development of standardized modular designs presents a promising approach to address scalability challenges, potentially reducing scaling costs by 20-30% through manufacturing efficiencies and simplified deployment processes.