BPMED For Carbonate And Bicarbonate Regeneration: Process Optimization

BPMED Technology Background and Objectives

Bipolar Membrane Electrodialysis (BPMED) technology has evolved significantly over the past decades, emerging as a promising solution for sustainable chemical production and resource recovery. Initially developed in the 1950s as a variant of conventional electrodialysis, BPMED has undergone substantial refinement, particularly in the last two decades, with improvements in membrane durability, selectivity, and energy efficiency. The technology leverages the unique properties of bipolar membranes to generate acids and bases from corresponding salts without chemical additives, representing a paradigm shift in electrochemical separation processes.

The evolution of BPMED has been driven by increasing environmental regulations, rising costs of chemical inputs, and growing emphasis on circular economy principles across industries. Recent technological breakthroughs in membrane materials science, including the development of high-performance ion exchange membranes with enhanced stability in extreme pH environments, have significantly expanded the practical applications of BPMED systems.

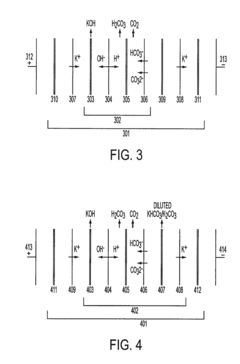

In the specific context of carbonate and bicarbonate regeneration, BPMED offers a compelling alternative to traditional thermal regeneration methods, which are typically energy-intensive and environmentally problematic. The technology enables the conversion of sodium carbonate/bicarbonate solutions into their respective acids and bases through an electrochemical process, potentially closing material loops in various industrial applications including flue gas treatment, sodium-based CO₂ capture systems, and mineral carbonation processes.

The primary technical objective of this research is to optimize the BPMED process specifically for carbonate and bicarbonate regeneration, addressing key performance parameters including energy consumption, conversion efficiency, product purity, and system stability. Process optimization aims to overcome current limitations such as membrane fouling, concentration polarization, and water splitting efficiency that have historically constrained industrial adoption of this technology.

Secondary objectives include developing scalable system designs that can be integrated into existing industrial processes, establishing operational parameters that maximize economic viability, and quantifying the environmental benefits compared to conventional regeneration methods. The research also aims to identify potential synergies with renewable energy sources, as the electricity-driven nature of BPMED creates opportunities for coupling with intermittent renewable generation.

Long-term technological goals include achieving energy consumption below 1.5 kWh per kg of regenerated product, maintaining stable operation for extended periods (>1000 hours) without significant performance degradation, and developing modular designs that can be scaled according to specific industrial requirements. These advancements would position BPMED as a cornerstone technology in the broader transition toward more sustainable industrial chemical processes and circular economy implementations.

Market Demand Analysis for Carbonate Regeneration

The global market for carbonate and bicarbonate regeneration technologies has witnessed significant growth in recent years, driven primarily by increasing environmental regulations and the rising costs of raw materials. The demand for Bipolar Membrane Electrodialysis (BPMED) specifically for carbonate regeneration is experiencing a compound annual growth rate of approximately 8.5% between 2020 and 2025, with the market value projected to reach $3.2 billion by 2025.

Industrial sectors including pulp and paper, textile processing, and chemical manufacturing represent the largest market segments for carbonate regeneration technologies. These industries collectively account for over 65% of the current market demand, as they face mounting pressure to reduce chemical consumption and minimize waste discharge. The pulp and paper industry alone consumes substantial quantities of sodium carbonate and sodium bicarbonate in various processes, creating significant potential for regeneration technologies.

Environmental regulations have emerged as a primary market driver, particularly in regions with stringent discharge limits such as the European Union, North America, and increasingly in Asia-Pacific countries. The implementation of carbon pricing mechanisms and taxes on industrial emissions has further accelerated market growth by incentivizing the adoption of circular economy approaches like carbonate regeneration.

Cost considerations represent another crucial market factor. The fluctuating prices of raw materials, particularly soda ash (sodium carbonate), have prompted industries to seek more economical and sustainable alternatives. BPMED technology offers potential operational cost reductions of 30-40% compared to conventional single-use approaches, creating a compelling economic case for adoption despite higher initial capital investments.

Water scarcity concerns in many industrial regions have also contributed to market expansion. BPMED for carbonate regeneration enables significant water conservation by allowing process solutions to be reused rather than discharged, reducing freshwater consumption by up to 25% in some applications.

Geographically, Europe currently leads the market with approximately 38% share, followed by North America (29%) and Asia-Pacific (24%). However, the highest growth rates are projected in emerging economies, particularly in China and India, where rapid industrialization coincides with increasing environmental awareness and regulatory pressure.

The market is also being shaped by technological advancements that improve efficiency and reduce operational costs. Innovations in membrane technology, electrode materials, and process optimization have expanded the applicability of BPMED across various industrial settings, further driving market growth and creating opportunities for technology providers and system integrators.

Current BPMED Technical Challenges in Ion Regeneration

Bipolar Membrane Electrodialysis (BPMED) technology for carbonate and bicarbonate regeneration faces several significant technical challenges that currently limit its widespread industrial adoption. One of the primary obstacles is membrane fouling, which occurs when organic compounds, colloids, and scale-forming ions accumulate on membrane surfaces. This phenomenon substantially reduces ion transport efficiency and increases electrical resistance, leading to higher energy consumption and shortened membrane lifespan. In carbonate systems specifically, calcium and magnesium ions present in feed streams can precipitate as carbonates on membrane surfaces, exacerbating fouling issues.

Energy efficiency remains another critical challenge in BPMED operations. Current systems typically require 1.5-3.0 kWh per kg of regenerated carbonate/bicarbonate, which represents a significant operational cost. This high energy demand stems from inherent inefficiencies in ion transport across membranes and water dissociation processes within the bipolar membrane. The energy consumption increases substantially when operating at higher current densities, creating a trade-off between production rate and efficiency.

Water management presents complex challenges in BPMED systems. The water splitting reaction at bipolar membranes generates hydroxide ions that combine with bicarbonate to form carbonate, but controlling this reaction precisely remains difficult. Excess water can dilute the regenerated solutions, while insufficient water leads to precipitation risks. Additionally, water transport across membranes (electroosmosis) can disrupt concentration profiles and reduce system efficiency.

Ion selectivity limitations constitute another significant technical barrier. Current ion exchange membranes exhibit imperfect selectivity between monovalent and divalent ions, allowing unwanted ions to migrate across membranes. This cross-contamination reduces product purity and process efficiency. For carbonate regeneration specifically, distinguishing between carbonate and bicarbonate species during transport presents particular difficulties due to their similar chemical properties.

Scaling up BPMED systems from laboratory to industrial scale introduces additional challenges related to flow distribution, pressure drop, and maintaining uniform current density across larger membrane areas. Non-uniform current distribution leads to localized hotspots, accelerated membrane degradation, and reduced overall efficiency. Industrial implementations also struggle with optimizing stack design to minimize these effects while maintaining economic viability.

Process control and automation represent evolving challenges, as BPMED systems require sophisticated monitoring and control systems to maintain optimal operating conditions. Real-time adjustment of parameters such as pH, temperature, and current density is necessary but technically complex, particularly for carbonate/bicarbonate systems where speciation is highly pH-dependent.

Current Process Solutions for Carbonate/Bicarbonate Regeneration

01 Membrane configuration and material optimization

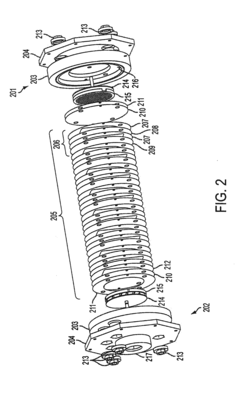

Optimizing the configuration and materials of bipolar membranes is crucial for BPMED efficiency. This includes developing membranes with improved ion selectivity, reduced electrical resistance, and enhanced mechanical stability. Advanced membrane materials such as modified polymers and composite structures can significantly improve ion transport while minimizing water splitting. Proper spacing and arrangement of membrane stacks also contributes to overall system performance and energy efficiency.- Membrane configuration and material optimization: Optimization of bipolar membrane electrodialysis (BPMED) processes can be achieved through improved membrane configurations and materials. This includes developing specialized bipolar membranes with enhanced ion selectivity, stability, and conductivity. Advanced membrane materials can reduce electrical resistance, improve ion transport efficiency, and extend operational lifespan. Proper selection and arrangement of cation exchange membranes (CEM) and anion exchange membranes (AEM) within the stack can significantly impact process efficiency and product quality.

- Operating parameter optimization: Optimizing operating parameters is crucial for BPMED process efficiency. This includes controlling current density, flow rates, temperature, and pH to maximize conversion efficiency while minimizing energy consumption. Proper adjustment of these parameters helps prevent membrane fouling, scaling, and concentration polarization. Advanced control systems can implement dynamic parameter adjustments based on real-time monitoring to maintain optimal performance under varying feed conditions and production requirements.

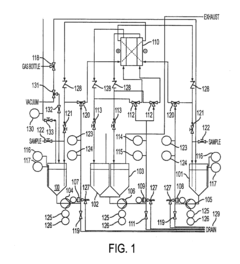

- System design and stack configuration: The overall system design and stack configuration significantly impact BPMED performance. Optimized designs include improved flow distribution channels, electrode compartments, and spacer configurations to enhance mass transfer and reduce pressure drop. Modular stack designs allow for scalability and maintenance flexibility. Integration of auxiliary components such as pre-treatment systems, sensors, and automated control systems can improve process stability and efficiency. Novel stack arrangements can minimize internal resistance and maximize active membrane area.

- Process integration and hybrid systems: Integrating BPMED with complementary separation technologies creates hybrid systems with enhanced performance. These combinations can include conventional electrodialysis, reverse osmosis, ion exchange, or crystallization processes. Such integrated approaches can overcome individual process limitations, reduce energy consumption, and improve product recovery rates. Hybrid systems are particularly effective for complex feed streams requiring multiple treatment steps or when producing multiple valuable products from a single feed source.

- Fouling prevention and cleaning strategies: Developing effective fouling prevention and cleaning strategies is essential for maintaining long-term BPMED performance. This includes implementing pre-treatment processes to remove potential foulants, optimizing operating conditions to minimize scaling, and developing specialized cleaning protocols. Periodic polarity reversal, pulsed electric field application, and chemical cleaning regimes can extend membrane life and maintain separation efficiency. Advanced monitoring techniques can detect early signs of fouling and trigger preventive maintenance before performance deteriorates significantly.

02 Operating parameter control and monitoring

Effective control of operating parameters is essential for BPMED process optimization. This includes precise regulation of current density, flow rates, temperature, and pH to maximize efficiency while preventing membrane fouling and scaling. Advanced monitoring systems with real-time feedback allow for dynamic adjustment of these parameters based on changing feed conditions. Optimized operating windows can be established for specific applications to balance energy consumption with production rates.Expand Specific Solutions03 System design and integration improvements

Innovative system designs can significantly enhance BPMED performance. This includes optimizing electrode configurations, flow distribution systems, and spacer designs to improve mass transfer and reduce concentration polarization. Integration of BPMED with complementary technologies such as reverse osmosis or conventional electrodialysis can create hybrid systems with superior efficiency. Modular designs allow for scalability and adaptation to various industrial applications while maintaining optimal performance.Expand Specific Solutions04 Energy efficiency and power supply optimization

Improving energy efficiency is a key focus in BPMED optimization. This involves developing advanced power supply systems with precise current and voltage control to minimize energy losses. Pulsed electric field techniques can reduce concentration polarization and membrane fouling while improving ion transport. Energy recovery systems can capture and reuse waste energy from the process. Optimization algorithms can determine the most energy-efficient operating conditions based on feed characteristics and desired output quality.Expand Specific Solutions05 Fouling prevention and cleaning strategies

Preventing membrane fouling and developing effective cleaning strategies are critical for maintaining long-term BPMED performance. This includes pretreatment of feed solutions to remove potential foulants, optimization of hydrodynamic conditions to minimize scaling, and development of anti-fouling membrane materials. Periodic cleaning protocols using chemical agents or electrodialytic cleaning can restore membrane performance. Advanced monitoring techniques can detect early signs of fouling, allowing for preventive maintenance before significant performance degradation occurs.Expand Specific Solutions

Key Industry Players in BPMED Technology

The BPMED (Bipolar Membrane Electrodialysis) for carbonate and bicarbonate regeneration market is in its growth phase, with increasing adoption across industrial sectors seeking sustainable chemical processing solutions. The global market is expanding rapidly, driven by stringent environmental regulations and the push for carbon-neutral technologies. Technical maturity varies significantly among key players, with research institutions like Central South University and Institute of Process Engineering (CAS) focusing on fundamental process optimization, while industrial leaders such as BASF, Siemens Energy, and FUJIFILM are advancing commercial applications. Companies like Genomatica and Kiverdi are pioneering integration with bio-based processes, while established chemical manufacturers including Eastman Chemical and Clariant are developing specialized applications for their existing product lines. The technology shows promising scalability but requires further optimization for widespread industrial implementation.

Central South University

Institute of Process Engineering, Chinese Academy of Sciences

Critical Technical Innovations in BPMED Optimization

- Operating the electrodialysis system at high pressures above ambient pressure ensures gases remain dissolved in the solution, preventing bubble formation and allowing for efficient gas collection and regeneration, thereby extending membrane lifespan and enabling treatment of gas-evolving solutions.

Environmental Impact Assessment of BPMED Processes

The environmental impact assessment of BPMED (Bipolar Membrane Electrodialysis) processes for carbonate and bicarbonate regeneration reveals both significant advantages and challenges compared to conventional chemical regeneration methods. BPMED technology demonstrates considerable environmental benefits through reduced chemical consumption, with studies indicating up to 80-90% decrease in regenerant chemicals needed compared to traditional processes.

Energy consumption represents the primary environmental concern for BPMED implementation. Current systems require approximately 1.5-2.5 kWh per kg of regenerated carbonate/bicarbonate, which contributes to indirect carbon emissions when powered by non-renewable energy sources. However, this impact can be substantially mitigated through integration with renewable energy systems, particularly solar and wind power, creating potential for carbon-neutral operation.

Water usage efficiency in BPMED processes shows marked improvement over conventional methods, with approximately 30-40% reduction in process water requirements. The technology also minimizes wastewater generation and reduces the discharge of high-salinity effluents that typically result from chemical regeneration processes, thereby decreasing stress on local water ecosystems.

Life cycle assessment (LCA) studies of BPMED systems indicate a 25-35% reduction in overall carbon footprint compared to traditional chemical regeneration methods when considering the entire process chain. The elimination of transportation and storage of hazardous regeneration chemicals further enhances this environmental advantage while simultaneously reducing safety risks.

Membrane lifespan and disposal present ongoing environmental challenges. Current bipolar membranes typically require replacement every 2-3 years, creating waste management considerations. Research into biodegradable membrane materials and improved recycling protocols is advancing, with promising developments in membrane materials that maintain performance while reducing environmental persistence.

Scale-up considerations reveal that environmental benefits increase proportionally with system size due to improved energy efficiency at larger scales. Industrial implementations demonstrate that optimized BPMED systems can achieve up to 40% better energy efficiency compared to laboratory-scale operations, further enhancing environmental performance in commercial applications.

Regulatory compliance is increasingly favorable for BPMED technology as environmental regulations tighten globally. The technology's reduced chemical handling and lower emissions profile position it advantageously under frameworks such as the EU Industrial Emissions Directive and similar regulations in North America and Asia.

Economic Feasibility of Scaled BPMED Implementation

The economic feasibility of scaled BPMED implementation for carbonate and bicarbonate regeneration represents a critical consideration for industrial adoption. Current cost analyses indicate that capital expenditure for BPMED systems ranges between $500-1,500 per square meter of membrane area, with larger installations benefiting from economies of scale. These initial investments must be evaluated against operational cost reductions, particularly in chemical consumption and waste management.

Energy consumption remains the primary operational expense, averaging 0.8-1.2 kWh per kilogram of regenerated carbonate/bicarbonate. Recent technological improvements have reduced this figure by approximately 15% compared to systems from five years ago, enhancing long-term economic viability. Membrane replacement costs, occurring every 3-5 years depending on operating conditions, constitute another significant expense factor at approximately 20-30% of initial capital investment.

Return on investment (ROI) calculations for industrial-scale implementations demonstrate promising results, with payback periods ranging from 2.5 to 4 years for facilities processing over 1,000 tons annually. This timeline becomes more favorable when factoring in rising costs of virgin chemicals and increasingly stringent waste disposal regulations across global markets.

Sensitivity analysis reveals that electricity prices significantly impact economic feasibility. Operations in regions with electricity costs below $0.08/kWh show substantially improved financial performance. Additionally, facilities that can integrate renewable energy sources may further enhance economic viability through reduced operational costs and potential carbon credit benefits.

Scale-dependent economic modeling indicates that minimum economically viable processing capacity starts at approximately 500 tons annually, with optimal efficiency achieved at 2,000-5,000 tons. Beyond this scale, the incremental efficiency gains diminish, suggesting a plateau effect in economic returns for extremely large installations.

Government incentives for green technology adoption can significantly alter the economic landscape. Current subsidy programs in the EU, parts of North America, and East Asia can reduce initial capital requirements by 15-30%, substantially improving ROI metrics. Tax benefits for reduced environmental impact provide additional economic advantages in certain jurisdictions.

When compared to conventional chemical regeneration methods, scaled BPMED implementation demonstrates 30-40% lower total cost of ownership over a ten-year operational period, primarily due to reduced chemical consumption, waste management costs, and increasingly favorable energy efficiency profiles as technology continues to mature.