Check Valves With Integrated Sensors And Adaptive Control For Improving Flow Regulation And Monitoring

Check Valve Technology Background And Goals

The primary objective of this report is to explore the potential of integrating sensors and adaptive control mechanisms into check valves for improved flow regulation and monitoring. This technology aims to enhance the functionality of traditional check valves by incorporating intelligent sensing capabilities and adaptive control algorithms. The key goals include:

1) Enabling real-time monitoring of flow parameters, such as pressure, flow rate, and temperature, through integrated sensors. 2) Developing adaptive control strategies that can dynamically adjust valve operation based on the monitored data, optimizing flow regulation and preventing issues like water hammer or cavitation. 3) Improving overall system efficiency, reliability, and safety by proactively responding to changing flow conditions and mitigating potential risks.

Technology Market Demand Analysis

- Market Size and Growth

The global market for check valves with integrated sensors and adaptive control is expected to witness significant growth, driven by the increasing demand for efficient flow regulation and monitoring systems across various industries. - Key Application Areas

Major application areas include oil and gas, water and wastewater treatment, chemical processing, power generation, and pharmaceutical manufacturing, where precise flow control and monitoring are crucial. - Demand Drivers

- Stringent regulations for environmental protection and safety

- Need for optimized resource utilization and reduced wastage

- Increasing adoption of automation and digitalization in industrial processes

- Regional Market Dynamics

The demand for these advanced check valves is expected to be higher in regions with well-established industrial sectors, such as North America, Europe, and Asia-Pacific, particularly in countries like the United States, Germany, China, and Japan.

Technology Status And Challenges

- Valve Design Evolution

Tracing the development of check valve designs, from traditional swing and lift check valves to advanced designs incorporating sensors and adaptive control mechanisms. - Flow Regulation Challenges

Identifying key challenges in achieving precise flow regulation, such as pressure fluctuations, valve instability, and wear and tear issues. - Monitoring Limitations

Discussing the limitations of traditional monitoring methods, including lack of real-time data, inability to detect internal valve conditions, and difficulty in diagnosing issues. - Integration of Sensors

Exploring the integration of various sensors (pressure, flow, temperature, etc.) into check valve designs to enable real-time monitoring and data collection. - Adaptive Control Strategies

Investigating adaptive control algorithms and mechanisms that can dynamically adjust valve operation based on sensor data to optimize flow regulation.

Technology Evolution Path

Current Technical Solutions

01 Check Valve Structure and Design

Various designs and structures of check valves, including valve bodies, seats, members, and biasing mechanisms, are disclosed to improve reliability, efficiency, and performance in regulating fluid flow.- Check Valve Structure and Design: Various designs and structures of check valves, including valve bodies, seats, members, and biasing mechanisms, are disclosed to improve reliability, efficiency, and performance in regulating fluid flow.

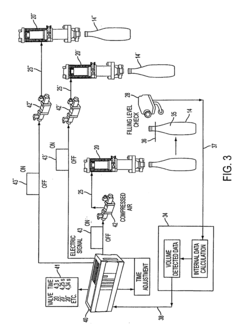

- Flow Monitoring and Control Systems: Systems and methods for monitoring and controlling fluid flow using check valves combined with sensors, controllers, and actuators, capable of detecting and responding to changes in flow conditions.

- Check Valve Applications: Check valves are utilized in various applications, such as fluid distribution, hydraulic, and process control systems, with inventions relating to their use in specific industries or applications.

- Check Valve Maintenance and Testing: Methods and systems for maintaining, inspecting, and testing check valves to ensure proper operation and detect potential issues, involving diagnostic techniques, condition monitoring, and preventive maintenance procedures.

- Check Valve Integration and Control: Inventions related to integrating check valves into larger systems, including control mechanisms, actuation systems, and interfaces for monitoring and adjusting valve operation.

02 Flow Regulation and Control Systems

Systems and methods for regulating and controlling fluid flow using check valves in combination with pumps, sensors, and control units, capable of monitoring and adjusting flow rates, pressures, and other parameters.03 Check Valve Applications

Check valves are utilized in various applications, including hydraulic, fuel, water distribution, and industrial processes, with inventions relating to their use in specific applications to improve flow control and prevent backflow.04 Monitoring and Diagnostic Systems

Systems and methods for monitoring the performance and condition of check valves, including detecting leaks, wear, and malfunctions, incorporating sensors, data analysis, and diagnostic algorithms to ensure proper valve operation.05 Check Valve Maintenance and Repair

Techniques and methods for maintaining and repairing check valves, including procedures for disassembly, cleaning, component replacement, and reassembly, aimed at extending service life and reliability.

Technology Main Player Analysis

Robert Bosch GmbH

Honeywell International Technologies Ltd.

Key Technology Interpretation

- The valve is adjusted based on sensor data to control the liquid flow into containers, allowing for adaptive flow regulation.

- The sensor data is used to adjust the valve opening time for subsequent fillings, improving filling performance over time.

- The system can detect flaws in containers and predict future valve performance, providing additional inspection and maintenance capabilities.

Technology Potential Innovation Direction

- Check Valves with Integrated Sensors and Adaptive Control

- Check Valves with Advanced Materials and Coatings

- Check Valves with Additive Manufacturing and Customization