Check Valves With Advanced Surface Coatings To Improve Performance And Durability

Technology Background And Goals

Key areas of focus include evaluating the adhesion strength and uniformity of coatings, assessing their compatibility with different valve materials, and analyzing their impact on factors such as pressure drop and leakage rates. The research should also consider the potential challenges and limitations associated with implementing these coatings in real-world applications, as well as their cost-effectiveness and scalability.

Check Valves Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, power generation, and water treatment. Provide statistics on the current market size and projected growth rate. - Industry Trends

Highlight key trends shaping the check valve market, such as the need for improved reliability, durability, and energy efficiency. Discuss the impact of stringent environmental regulations and the adoption of advanced materials and coatings. - Application Analysis

Analyze the demand for check valves across various applications, including oil and gas pipelines, chemical processing plants, power plants, water treatment facilities, and others. Identify the specific requirements and challenges faced in each application. - Regional Insights

Provide insights into the regional dynamics of the check valve market, highlighting the major demand centers and growth opportunities in different regions, such as North America, Europe, Asia-Pacific, and others.

Technology Status And Challenges

- Valve Coatings Overview

Coatings enhance valve performance and durability by protecting against corrosion, wear, and fouling. Common coatings include ceramics, polymers, and metal alloys. - Coating Challenges

Key challenges include adhesion issues, thermal and chemical stability, porosity, and compatibility with valve materials and operating conditions. - Geographic Distribution

Valve coating technology is widely researched globally, with major contributions from the US, Europe, China, and Japan.

Current Technical Solutions

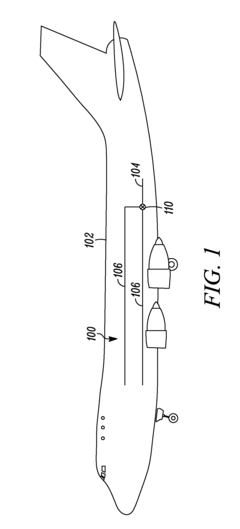

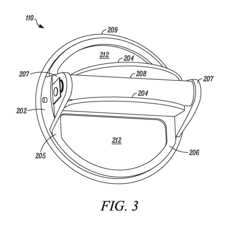

01 Check Valve Structure and Components

The valve body, valve seat, valve disc or ball, and other components impact flow efficiency, sealing ability, wear and corrosion resistance.- Check Valve Structure and Components: The valve body, valve seat, valve disc or ball, spring mechanism, and sealing components determine performance and durability. Their design and materials affect flow efficiency, sealing capability, wear and corrosion resistance.

- Check Valve Materials and Coatings: Metals, plastics, composites, and coatings impact performance and durability. Material properties like strength, corrosion resistance, and fluid compatibility are crucial.

- Check Valve Design and Flow Characteristics: Geometry, flow path, and opening/closing mechanisms affect performance. Factors like flow rate, pressure drop, backflow prevention, and water hammer are important considerations.

- Check Valve Maintenance and Inspection: Regular maintenance, cleaning, lubrication, component replacement, and testing ensure continued performance and durability. Proper procedures and schedules extend service life.

- Check Valve Applications and Operating Conditions: Fluid properties, temperature, pressure, and environmental conditions influence performance and durability. Selecting and designing valves based on operating conditions ensures reliable operation.

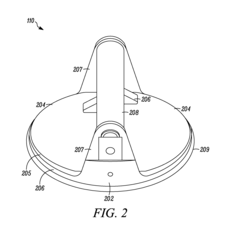

02 Check Valve Sealing Mechanisms

Sealing materials like elastomers or metal-to-metal seals, and sealing geometries and configurations, ensure proper operation and prevent leakage, maintaining performance and durability.Expand Specific Solutions03 Check Valve Materials and Coatings

Materials like stainless steel, bronze, and alloys, and coatings like nickel or chrome plating, impact corrosion resistance, wear resistance, and fluid compatibility, enhancing durability.Expand Specific Solutions04 Check Valve Flow Characteristics

Pressure drop, flow capacity, and flow patterns affect performance and durability. Optimizing these characteristics through design and sizing ensures efficient operation and extends service life.Expand Specific Solutions05 Check Valve Maintenance and Testing

Regular inspections, preventive maintenance, and testing under various conditions identify issues and degradation. Adherence to recommended practices extends service life and prevents failures.Expand Specific Solutions

Technology Main Player Analysis

Tenneco Automotive Operating Co., Inc.

Cameron International Corp.

Key Technology Interpretation

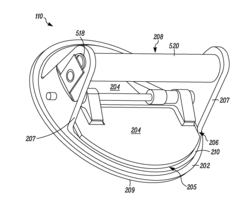

- The seat region is made of elastomer material to provide a better seal with the flapper when in the closed position.

- The invention provides a check valve with multiple flappers and a stop to improve the sealing performance of the valve.

- The technical effects of the invention include improved sealing performance, reduced fluid leakage, and improved control over fluid flow.

Regulatory and Environmental Factors

Regulatory and environmental factors play a crucial role in the development and application of advanced surface coatings for check valves. These coatings are designed to enhance the performance and durability of check valves, which are essential components in various industrial processes, including oil and gas, chemical, and power generation industries.

Firstly, the coatings must comply with relevant industry standards and regulations. For instance, in the oil and gas industry, coatings used in check valves must meet the stringent requirements set by organizations like the American Petroleum Institute (API) and the International Organization for Standardization (ISO). These standards ensure the safety, reliability, and performance of the coated check valves under various operating conditions.

Environmental regulations also significantly influence the development and application of advanced surface coatings. Many countries have implemented strict regulations to minimize the environmental impact of industrial processes and products. For example, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union aims to protect human health and the environment from the risks posed by chemicals. Coatings used in check valves must comply with these regulations, ensuring they do not contain hazardous substances or pose environmental risks during their lifecycle.

Furthermore, the coatings must be designed to withstand harsh operating environments, such as high temperatures, pressures, and corrosive media. These conditions can accelerate the degradation of coatings, leading to premature failure and potential environmental contamination. Advanced surface coatings must demonstrate superior resistance to these environmental factors, ensuring the long-term performance and reliability of check valves.

Additionally, the environmental impact of the coating application process itself must be considered. Certain coating techniques may involve the use of hazardous materials or generate harmful emissions. Manufacturers must adopt environmentally friendly coating processes and implement appropriate waste management practices to minimize their environmental footprint.

In summary, regulatory and environmental factors play a pivotal role in the development and application of advanced surface coatings for check valves. Compliance with industry standards, environmental regulations, and the ability to withstand harsh operating conditions are essential considerations. Manufacturers must strike a balance between enhancing check valve performance and minimizing environmental impact throughout the product lifecycle.

Performance Metrics and Testing

Performance metrics and testing are crucial aspects in evaluating the effectiveness of advanced surface coatings on check valves. Several key parameters need to be considered and measured to assess the coating's impact on valve performance.

Firstly, flow characteristics should be thoroughly examined. This includes measuring the pressure drop across the valve under various flow conditions, as well as assessing the valve's ability to prevent backflow. Advanced coatings can potentially reduce friction and turbulence, leading to improved flow efficiency and lower pressure losses.

Secondly, the coating's durability and resistance to wear should be evaluated. Accelerated life testing can be conducted by subjecting the coated valves to simulated harsh environments, such as high temperatures, corrosive media, and cyclic loading. The coating's adhesion, erosion resistance, and overall integrity should be monitored over time.

Thirdly, the coating's impact on valve sealing and leakage rates should be quantified. Precise measurements of leakage rates under various pressure differentials and temperature conditions can reveal the coating's ability to enhance sealing performance and prevent leakage.

Furthermore, the coating's compatibility with different media should be assessed. This includes testing with various fluids, such as water, oils, chemicals, and gases, to ensure the coating does not degrade or react adversely with the media.

In addition to performance testing, surface characterization techniques should be employed to analyze the coating's properties. These may include microscopy, surface roughness measurements, and chemical analysis to understand the coating's composition, structure, and morphology.

Finally, standardized testing protocols and industry-specific guidelines should be followed to ensure the validity and comparability of the test results. This may involve adhering to standards set by organizations such as ASME, API, or ISO.

By conducting comprehensive performance testing and analysis, the true potential of advanced surface coatings on check valves can be accurately evaluated, paving the way for improved valve performance, reliability, and longevity in various industrial applications.