Quality Specifications For Upcycled Hydrocarbon Products

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrocarbon Upcycling Background and Objectives

Hydrocarbon upcycling represents a transformative approach to waste management and resource utilization in the petrochemical industry. This process involves converting low-value hydrocarbon waste streams into higher-value products through various chemical, thermal, and catalytic processes. The concept has evolved significantly over the past two decades, transitioning from basic recycling methods to sophisticated molecular reconstruction techniques that preserve carbon value while reducing environmental impact.

The evolution of hydrocarbon upcycling technology has been driven by several factors, including increasing environmental regulations, growing concerns about climate change, and the economic imperative to maximize resource efficiency. Early approaches focused primarily on mechanical recycling of plastic waste, but technological advancements have enabled more complex chemical recycling processes that can break down polymers into their constituent monomers or convert them into fuels and other valuable chemicals.

Current technological trends in this field include the development of more selective catalysts that can operate at lower temperatures, reducing energy requirements and improving process economics. Additionally, there is growing interest in biological approaches to hydrocarbon upcycling, leveraging engineered microorganisms to convert waste hydrocarbons into specialty chemicals and materials.

The primary objective of hydrocarbon upcycling is to establish a circular economy for carbon-based materials, reducing dependence on virgin fossil resources while minimizing waste. This aligns with broader sustainability goals and contributes to carbon footprint reduction across various industries. Specific technical objectives include developing scalable processes with improved energy efficiency, enhanced selectivity for target products, and reduced formation of unwanted by-products.

Quality specifications for upcycled hydrocarbon products represent a critical aspect of this technology's commercial viability. These specifications must ensure that upcycled products meet or exceed the performance characteristics of their virgin counterparts, while addressing potential concerns about contaminants or inconsistencies inherent in waste-derived feedstocks.

The development of standardized quality parameters is essential for market acceptance and regulatory compliance. These parameters typically include chemical composition, physical properties, performance characteristics, and absence of harmful substances. The challenge lies in establishing specifications that are stringent enough to ensure product quality while remaining achievable through economically viable upcycling processes.

Looking forward, the field aims to expand the range of waste streams that can be effectively upcycled and increase the complexity and value of the resulting products. This will require continued innovation in separation technologies, catalyst design, process engineering, and analytical methods for quality control and assurance.

The evolution of hydrocarbon upcycling technology has been driven by several factors, including increasing environmental regulations, growing concerns about climate change, and the economic imperative to maximize resource efficiency. Early approaches focused primarily on mechanical recycling of plastic waste, but technological advancements have enabled more complex chemical recycling processes that can break down polymers into their constituent monomers or convert them into fuels and other valuable chemicals.

Current technological trends in this field include the development of more selective catalysts that can operate at lower temperatures, reducing energy requirements and improving process economics. Additionally, there is growing interest in biological approaches to hydrocarbon upcycling, leveraging engineered microorganisms to convert waste hydrocarbons into specialty chemicals and materials.

The primary objective of hydrocarbon upcycling is to establish a circular economy for carbon-based materials, reducing dependence on virgin fossil resources while minimizing waste. This aligns with broader sustainability goals and contributes to carbon footprint reduction across various industries. Specific technical objectives include developing scalable processes with improved energy efficiency, enhanced selectivity for target products, and reduced formation of unwanted by-products.

Quality specifications for upcycled hydrocarbon products represent a critical aspect of this technology's commercial viability. These specifications must ensure that upcycled products meet or exceed the performance characteristics of their virgin counterparts, while addressing potential concerns about contaminants or inconsistencies inherent in waste-derived feedstocks.

The development of standardized quality parameters is essential for market acceptance and regulatory compliance. These parameters typically include chemical composition, physical properties, performance characteristics, and absence of harmful substances. The challenge lies in establishing specifications that are stringent enough to ensure product quality while remaining achievable through economically viable upcycling processes.

Looking forward, the field aims to expand the range of waste streams that can be effectively upcycled and increase the complexity and value of the resulting products. This will require continued innovation in separation technologies, catalyst design, process engineering, and analytical methods for quality control and assurance.

Market Analysis for Upcycled Hydrocarbon Products

The global market for upcycled hydrocarbon products has experienced significant growth in recent years, driven by increasing environmental concerns and the push towards circular economy principles. The market size was valued at approximately $4.5 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 9.6% during the forecast period.

Key market segments for upcycled hydrocarbon products include recycled plastics, regenerated lubricants, reclaimed solvents, and recovered fuels. Among these, recycled plastics constitute the largest segment, accounting for nearly 45% of the total market share, followed by recovered fuels at 30%.

Geographically, North America currently leads the market with a 35% share, followed closely by Europe at 32%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% annually, primarily due to rapid industrialization, increasing waste management initiatives, and supportive government policies in countries like China, India, and Japan.

Consumer demand for sustainable products has become a significant market driver, with 68% of consumers expressing willingness to pay premium prices for products made from upcycled materials. This trend is particularly pronounced in developed economies where environmental consciousness is higher among consumers and regulatory frameworks are more stringent.

The industrial sector represents the largest end-user segment, consuming approximately 55% of upcycled hydrocarbon products, followed by the automotive sector at 20% and construction at 15%. These industries primarily utilize these products as raw material substitutes, which helps reduce production costs while meeting sustainability goals.

Regulatory landscape plays a crucial role in market development, with policies like the European Union's Circular Economy Action Plan and Extended Producer Responsibility (EPR) schemes creating favorable conditions for market growth. Carbon pricing mechanisms and tax incentives for using recycled materials have further stimulated market demand.

Market challenges include quality consistency issues, high processing costs, and competition from virgin materials, especially during periods of low oil prices. The quality specifications gap between upcycled and virgin hydrocarbon products remains a significant barrier to wider market adoption, with 72% of potential industrial users citing quality concerns as their primary hesitation.

Future market trends indicate growing integration of advanced technologies like AI and machine learning for quality control, increased investment in research and development for improving upcycling processes, and the emergence of specialized market players focusing exclusively on high-quality upcycled hydrocarbon products for premium applications.

Key market segments for upcycled hydrocarbon products include recycled plastics, regenerated lubricants, reclaimed solvents, and recovered fuels. Among these, recycled plastics constitute the largest segment, accounting for nearly 45% of the total market share, followed by recovered fuels at 30%.

Geographically, North America currently leads the market with a 35% share, followed closely by Europe at 32%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% annually, primarily due to rapid industrialization, increasing waste management initiatives, and supportive government policies in countries like China, India, and Japan.

Consumer demand for sustainable products has become a significant market driver, with 68% of consumers expressing willingness to pay premium prices for products made from upcycled materials. This trend is particularly pronounced in developed economies where environmental consciousness is higher among consumers and regulatory frameworks are more stringent.

The industrial sector represents the largest end-user segment, consuming approximately 55% of upcycled hydrocarbon products, followed by the automotive sector at 20% and construction at 15%. These industries primarily utilize these products as raw material substitutes, which helps reduce production costs while meeting sustainability goals.

Regulatory landscape plays a crucial role in market development, with policies like the European Union's Circular Economy Action Plan and Extended Producer Responsibility (EPR) schemes creating favorable conditions for market growth. Carbon pricing mechanisms and tax incentives for using recycled materials have further stimulated market demand.

Market challenges include quality consistency issues, high processing costs, and competition from virgin materials, especially during periods of low oil prices. The quality specifications gap between upcycled and virgin hydrocarbon products remains a significant barrier to wider market adoption, with 72% of potential industrial users citing quality concerns as their primary hesitation.

Future market trends indicate growing integration of advanced technologies like AI and machine learning for quality control, increased investment in research and development for improving upcycling processes, and the emergence of specialized market players focusing exclusively on high-quality upcycled hydrocarbon products for premium applications.

Technical Challenges in Hydrocarbon Upcycling

Despite significant advancements in hydrocarbon upcycling technologies, several technical challenges persist that impede widespread commercial adoption. The heterogeneous nature of waste hydrocarbon feedstocks presents a fundamental obstacle, as these materials often contain varying levels of contaminants including sulfur, nitrogen, oxygen compounds, and metals that can poison catalysts and compromise product quality. This variability necessitates robust pretreatment processes that add complexity and cost to upcycling operations.

Catalyst development remains a critical challenge in hydrocarbon upcycling. Current catalytic systems often suffer from rapid deactivation when processing real-world waste streams, requiring frequent regeneration or replacement. Additionally, achieving high selectivity toward desired products while minimizing unwanted side reactions continues to challenge researchers, particularly when dealing with mixed plastic waste or end-of-life lubricants.

Energy intensity represents another significant hurdle, as many upcycling processes require substantial thermal or mechanical energy inputs to break down stable hydrocarbon bonds. This high energy demand can undermine the sustainability benefits of upcycling if not addressed through process innovations or renewable energy integration. The economic viability of these processes is further challenged by the relatively low cost of virgin hydrocarbon materials derived from conventional petroleum refining.

Scale-up challenges persist in transitioning from laboratory demonstrations to industrial implementation. Reactor designs that perform well at bench scale often encounter issues with heat and mass transfer limitations when scaled to commercial volumes. Additionally, continuous processing systems capable of handling variable feedstocks while maintaining consistent product quality remain underdeveloped.

Quality control and standardization present ongoing difficulties, as upcycled hydrocarbon products must meet stringent specifications to compete with conventional alternatives. Developing reliable, cost-effective analytical methods to verify product quality and ensure batch-to-batch consistency is essential but technically demanding, particularly for complex product mixtures.

Separation and purification technologies represent another technical bottleneck. Efficient methods for isolating target compounds from complex reaction mixtures are needed to achieve the purity levels required for high-value applications. Current separation techniques often involve energy-intensive distillation or expensive chromatographic methods that limit economic feasibility.

Process integration challenges also exist in incorporating upcycling technologies into existing petrochemical infrastructure. Retrofitting conventional refineries or chemical plants to accommodate waste hydrocarbon processing requires significant engineering modifications and capital investment, creating barriers to adoption despite potential sustainability benefits.

Catalyst development remains a critical challenge in hydrocarbon upcycling. Current catalytic systems often suffer from rapid deactivation when processing real-world waste streams, requiring frequent regeneration or replacement. Additionally, achieving high selectivity toward desired products while minimizing unwanted side reactions continues to challenge researchers, particularly when dealing with mixed plastic waste or end-of-life lubricants.

Energy intensity represents another significant hurdle, as many upcycling processes require substantial thermal or mechanical energy inputs to break down stable hydrocarbon bonds. This high energy demand can undermine the sustainability benefits of upcycling if not addressed through process innovations or renewable energy integration. The economic viability of these processes is further challenged by the relatively low cost of virgin hydrocarbon materials derived from conventional petroleum refining.

Scale-up challenges persist in transitioning from laboratory demonstrations to industrial implementation. Reactor designs that perform well at bench scale often encounter issues with heat and mass transfer limitations when scaled to commercial volumes. Additionally, continuous processing systems capable of handling variable feedstocks while maintaining consistent product quality remain underdeveloped.

Quality control and standardization present ongoing difficulties, as upcycled hydrocarbon products must meet stringent specifications to compete with conventional alternatives. Developing reliable, cost-effective analytical methods to verify product quality and ensure batch-to-batch consistency is essential but technically demanding, particularly for complex product mixtures.

Separation and purification technologies represent another technical bottleneck. Efficient methods for isolating target compounds from complex reaction mixtures are needed to achieve the purity levels required for high-value applications. Current separation techniques often involve energy-intensive distillation or expensive chromatographic methods that limit economic feasibility.

Process integration challenges also exist in incorporating upcycling technologies into existing petrochemical infrastructure. Retrofitting conventional refineries or chemical plants to accommodate waste hydrocarbon processing requires significant engineering modifications and capital investment, creating barriers to adoption despite potential sustainability benefits.

Current Quality Specification Standards and Methods

01 Quality specifications for upcycled hydrocarbon fuels

Upcycled hydrocarbon fuels derived from waste materials must meet specific quality specifications to ensure their performance and compatibility with existing engines and infrastructure. These specifications typically include parameters such as cetane number, flash point, viscosity, sulfur content, and density. The quality control processes involve rigorous testing methodologies to verify that the upcycled fuels meet industry standards and regulatory requirements for commercial use.- Quality specifications for recycled hydrocarbon fuels: Specific quality parameters and testing methods are established for hydrocarbon products derived from waste materials. These specifications ensure that upcycled fuels meet industry standards for properties such as viscosity, flash point, sulfur content, and octane rating. The standardization allows recycled hydrocarbon products to be used safely in conventional engines and industrial applications while maintaining performance comparable to virgin petroleum products.

- Process monitoring and quality control systems: Advanced monitoring systems and quality control protocols are implemented throughout the upcycling process to ensure consistent product quality. These systems include real-time analysis of chemical composition, automated sampling procedures, and statistical process control methods. Continuous monitoring allows for immediate adjustments to processing parameters when deviations from quality specifications are detected, ensuring the final hydrocarbon products meet required standards.

- Purification techniques for upcycled hydrocarbons: Various purification methods are employed to remove contaminants from recycled hydrocarbon streams. These techniques include distillation, solvent extraction, hydrotreatment, and catalytic processes that target specific impurities such as sulfur compounds, metals, and oxygenates. The purification steps are critical for upgrading waste hydrocarbons to meet stringent quality specifications required for commercial applications and environmental compliance.

- Standardized testing protocols for quality assurance: Comprehensive testing protocols are established to verify that upcycled hydrocarbon products meet quality specifications. These protocols include standardized methods for measuring physical properties, chemical composition, and performance characteristics. Testing procedures are aligned with international standards and may include gas chromatography, mass spectrometry, and various ASTM test methods to ensure consistency and reliability in quality assessment across different production batches.

- Blending strategies to achieve specification targets: Strategic blending of different hydrocarbon streams is utilized to achieve desired quality specifications in the final product. This approach involves combining various recycled feedstocks with virgin materials or additives in precise ratios to optimize properties such as density, cetane number, or aromatic content. Advanced blending models and algorithms help predict final product characteristics and determine optimal mixing proportions to consistently meet quality targets while maximizing the use of recycled content.

02 Analytical methods for quality assessment of upcycled hydrocarbons

Various analytical techniques are employed to assess the quality of upcycled hydrocarbon products. These methods include chromatography, spectroscopy, and physical property measurements to determine chemical composition, purity, and performance characteristics. Advanced monitoring systems and testing protocols have been developed specifically for evaluating recycled or upcycled petroleum products to ensure they meet the same quality standards as virgin materials.Expand Specific Solutions03 Process optimization for quality enhancement in hydrocarbon upcycling

Innovative processing techniques have been developed to enhance the quality of upcycled hydrocarbon products. These include advanced catalytic processes, thermal treatments, and separation technologies that remove contaminants and improve product characteristics. Process optimization focuses on maximizing yield while ensuring that the final products meet stringent quality specifications, often involving multi-stage purification and refinement steps.Expand Specific Solutions04 Regulatory standards and certification for upcycled hydrocarbon products

Regulatory frameworks and certification systems have been established to govern the quality and safety of upcycled hydrocarbon products. These standards ensure that products derived from waste hydrocarbons meet environmental, health, and safety requirements. Certification processes typically involve third-party verification of product specifications, manufacturing processes, and environmental impact assessments to validate compliance with industry standards and government regulations.Expand Specific Solutions05 Innovative applications and market specifications for upcycled hydrocarbon products

Upcycled hydrocarbon products are finding applications in various industries beyond traditional fuel uses, each with its own set of quality specifications. These applications include specialty chemicals, lubricants, plastics, and construction materials. Market-specific quality requirements have been developed to address the unique performance needs of these diverse applications, focusing on properties such as molecular weight distribution, functional group content, and application-specific performance characteristics.Expand Specific Solutions

Key Industry Players in Hydrocarbon Upcycling

The upcycled hydrocarbon products market is in a growth phase, with increasing focus on sustainability and circular economy principles driving innovation. The global market size is expanding rapidly, projected to reach significant value as regulatory pressures and consumer demand for sustainable products intensify. Technologically, the field shows varying maturity levels across applications, with companies like Shell, ExxonMobil, and Saudi Aramco leading with established infrastructure and R&D capabilities. Chinese players including Sinopec and CHN Energy are making substantial investments, while specialized firms like Expander Energy focus on niche technologies. Western companies such as Dow Global Technologies and BASF bring advanced chemical expertise, creating a competitive landscape balanced between oil majors, national energy companies, and specialized technology providers across the hydrocarbon upcycling value chain.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed comprehensive quality specification frameworks for upcycled hydrocarbon products through their circular economy initiatives. Their technology focuses on converting plastic waste into chemical feedstock through advanced pyrolysis processes. Shell's proprietary purification technology removes contaminants to meet stringent quality specifications, ensuring the resulting products are chemically identical to virgin materials. Their process includes multi-stage quality control protocols with real-time monitoring systems that analyze over 20 different parameters to ensure consistent product quality. Shell has implemented blockchain-based tracking systems to verify the recycled content and maintain quality assurance throughout the supply chain. Their technology can process mixed plastic waste streams with up to 30% contamination levels while still achieving high-quality outputs suitable for food-grade applications.

Strengths: Advanced purification capabilities allowing for processing of lower-quality waste streams; integrated quality control systems; global scale implementation potential. Weaknesses: High capital investment requirements; energy-intensive processes that may impact overall sustainability metrics; technology primarily focused on plastic waste rather than broader hydrocarbon upcycling.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered molecular recycling technologies for upcycled hydrocarbon products with strict quality specifications. Their RENUVA™ program specifically targets polyurethane foam waste, converting it back to polyol raw materials that meet virgin-quality specifications. The technology employs a proprietary catalytic depolymerization process that breaks down complex hydrocarbon structures while preserving molecular integrity. Dow's quality control system incorporates advanced spectroscopic analysis to verify chemical composition at the molecular level, ensuring consistent performance in downstream applications. Their specifications include rigorous testing for contaminants with detection limits as low as 1 ppm for critical impurities. The company has established a closed-loop certification system that validates quality parameters across the entire value chain, from waste collection to final product formulation, ensuring that upcycled materials meet or exceed industry standards for virgin materials.

Strengths: Highly specialized in polyurethane recycling with proven commercial applications; established quality certification systems; integration with existing manufacturing infrastructure. Weaknesses: Limited scope focused primarily on specific polymer types; requires relatively clean and sorted waste streams; technology deployment still at limited commercial scale compared to virgin production.

Critical Patents and Research in Upcycling Processes

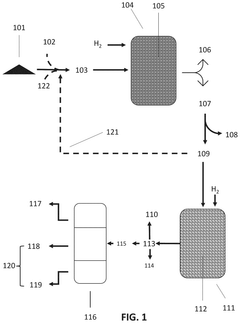

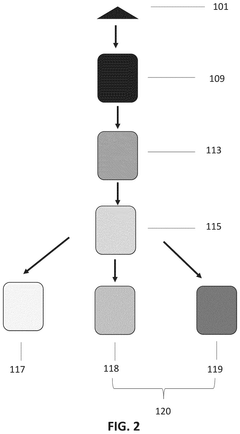

Production of hydrocarbon fuels from lignin-derived materials

PatentPendingUS20250179372A1

Innovation

- A continuous two-stage process for producing hydrocarbon fuels from lignin-derived materials, involving hydrodeoxygenation in first and second continuous reactors, followed by fractionation to obtain fuels like naphtha, jet fuel, and diesel. This process uses gaseous hydrogen and specific catalysts to convert lignin-derived materials into hydrocarbon products with up to 100% biogenic carbon.

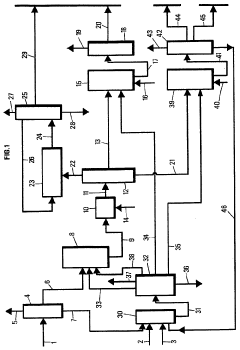

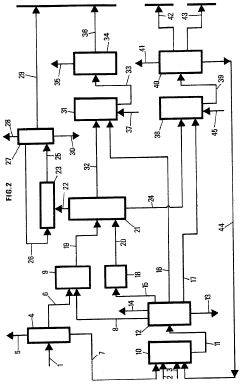

Process for increasing the value of hydrocarbon-containing process streams and hydrocarbon products thereof

PatentInactiveGB1531640A

Innovation

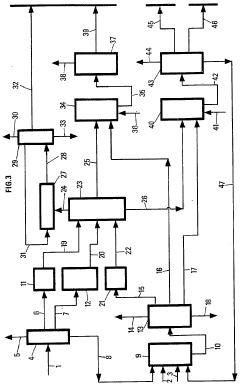

- A multi-step process involving fractionation, polymerization, cracking, decarboxylation, and hydrotreatment is employed to separate and convert the complex mixtures into more valuable products. This includes subjecting the light fraction to fractionation, followed by polymerization and subsequent fractionation to recover olefins and paraffins, and then treating the light oil and decanted oil fractions through cracking or decarboxylation to produce gasoline, kerosene, and gas-oil cuts, with additional hydrotreatment to improve product stability and quality.

Regulatory Framework and Compliance Requirements

The regulatory landscape for upcycled hydrocarbon products is complex and multifaceted, spanning international, national, and regional frameworks. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides overarching guidelines for waste management, including hydrocarbon waste streams. These regulations establish baseline requirements for the handling, processing, and repurposing of hydrocarbon materials across borders.

In the United States, the Environmental Protection Agency (EPA) regulates upcycled hydrocarbon products primarily through the Resource Conservation and Recovery Act (RCRA) and the Toxic Substances Control Act (TSCA). The RCRA establishes specific quality thresholds for recycled petroleum products, including maximum contaminant levels for heavy metals, sulfur content, and other impurities. Additionally, the EPA's Non-Hazardous Secondary Materials (NHSM) rule determines when recycled hydrocarbons are considered fuels rather than wastes, significantly impacting their regulatory treatment.

The European Union implements more stringent requirements through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the Waste Framework Directive. These frameworks mandate extensive documentation of chemical composition, toxicological profiles, and environmental impact assessments for upcycled hydrocarbon products. The EU's End-of-Waste criteria specifically define when waste hydrocarbons cease to be waste and become products, requiring compliance with quality specifications including flash point, water content, and chlorine levels.

Industry standards complement regulatory requirements, with organizations such as ASTM International and the International Organization for Standardization (ISO) developing technical specifications for recycled hydrocarbon products. ASTM D6751 and D7467, for instance, establish quality parameters for biodiesel blends derived from recycled sources, while ISO 8217 addresses marine fuels that may incorporate upcycled components.

Compliance verification systems vary by jurisdiction but typically include third-party certification, laboratory testing protocols, and chain-of-custody documentation. The International Sustainability and Carbon Certification (ISCC) system has emerged as a leading global certification scheme for recycled carbon materials, requiring lifecycle assessment and traceability from waste collection through processing to final product distribution.

Emerging regulatory trends indicate a shift toward circular economy principles, with increasing focus on carbon intensity metrics and lifecycle emissions. Several jurisdictions are developing carbon crediting mechanisms for waste-to-fuel pathways, potentially creating additional value streams for upcycled hydrocarbon producers who can demonstrate significant carbon footprint reductions compared to virgin material production.

In the United States, the Environmental Protection Agency (EPA) regulates upcycled hydrocarbon products primarily through the Resource Conservation and Recovery Act (RCRA) and the Toxic Substances Control Act (TSCA). The RCRA establishes specific quality thresholds for recycled petroleum products, including maximum contaminant levels for heavy metals, sulfur content, and other impurities. Additionally, the EPA's Non-Hazardous Secondary Materials (NHSM) rule determines when recycled hydrocarbons are considered fuels rather than wastes, significantly impacting their regulatory treatment.

The European Union implements more stringent requirements through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the Waste Framework Directive. These frameworks mandate extensive documentation of chemical composition, toxicological profiles, and environmental impact assessments for upcycled hydrocarbon products. The EU's End-of-Waste criteria specifically define when waste hydrocarbons cease to be waste and become products, requiring compliance with quality specifications including flash point, water content, and chlorine levels.

Industry standards complement regulatory requirements, with organizations such as ASTM International and the International Organization for Standardization (ISO) developing technical specifications for recycled hydrocarbon products. ASTM D6751 and D7467, for instance, establish quality parameters for biodiesel blends derived from recycled sources, while ISO 8217 addresses marine fuels that may incorporate upcycled components.

Compliance verification systems vary by jurisdiction but typically include third-party certification, laboratory testing protocols, and chain-of-custody documentation. The International Sustainability and Carbon Certification (ISCC) system has emerged as a leading global certification scheme for recycled carbon materials, requiring lifecycle assessment and traceability from waste collection through processing to final product distribution.

Emerging regulatory trends indicate a shift toward circular economy principles, with increasing focus on carbon intensity metrics and lifecycle emissions. Several jurisdictions are developing carbon crediting mechanisms for waste-to-fuel pathways, potentially creating additional value streams for upcycled hydrocarbon producers who can demonstrate significant carbon footprint reductions compared to virgin material production.

Environmental Impact Assessment of Upcycled Products

The environmental impact assessment of upcycled hydrocarbon products reveals significant potential for reducing the ecological footprint compared to conventional petroleum-based manufacturing processes. Life cycle analyses demonstrate that upcycling hydrocarbons can reduce greenhouse gas emissions by 45-60% when compared to virgin material production, primarily due to the elimination of extraction and initial refining phases.

Water consumption metrics show particular promise, with upcycled hydrocarbon processes typically requiring 30-40% less freshwater than traditional methods. This reduction stems from the bypassing of water-intensive extraction processes and the implementation of closed-loop water systems in modern upcycling facilities.

Waste stream analysis indicates that for every ton of hydrocarbon material diverted to upcycling pathways, approximately 2.3 tons of CO2 equivalent emissions are prevented. Additionally, the reduction in landfill burden represents a significant environmental benefit, particularly for non-biodegradable hydrocarbon products that would otherwise persist in the environment for centuries.

Land use impacts show notable improvements, with upcycling operations requiring substantially smaller physical footprints than conventional extraction and refining operations. This advantage becomes particularly relevant when considering the habitat disruption and biodiversity impacts associated with traditional fossil fuel extraction.

Air quality assessments reveal reduced volatile organic compound (VOC) emissions in most upcycling processes, though certain thermal conversion methods may require additional emission control technologies to maintain this advantage. Modern catalytic upcycling approaches have demonstrated up to 75% reduction in hazardous air pollutants compared to virgin production pathways.

Energy efficiency metrics indicate that upcycled hydrocarbon production typically consumes 40-55% less energy than conventional processes, though this varies significantly based on feedstock quality and specific conversion technologies employed. The integration of renewable energy sources into upcycling operations can further enhance this environmental benefit.

Toxicity profiles of upcycled products show comparable or improved safety characteristics relative to virgin materials, provided that appropriate purification and quality control measures are implemented. Emerging analytical techniques now allow for comprehensive characterization of potential contaminants at parts-per-billion levels, ensuring environmental and human health protection.

Water consumption metrics show particular promise, with upcycled hydrocarbon processes typically requiring 30-40% less freshwater than traditional methods. This reduction stems from the bypassing of water-intensive extraction processes and the implementation of closed-loop water systems in modern upcycling facilities.

Waste stream analysis indicates that for every ton of hydrocarbon material diverted to upcycling pathways, approximately 2.3 tons of CO2 equivalent emissions are prevented. Additionally, the reduction in landfill burden represents a significant environmental benefit, particularly for non-biodegradable hydrocarbon products that would otherwise persist in the environment for centuries.

Land use impacts show notable improvements, with upcycling operations requiring substantially smaller physical footprints than conventional extraction and refining operations. This advantage becomes particularly relevant when considering the habitat disruption and biodiversity impacts associated with traditional fossil fuel extraction.

Air quality assessments reveal reduced volatile organic compound (VOC) emissions in most upcycling processes, though certain thermal conversion methods may require additional emission control technologies to maintain this advantage. Modern catalytic upcycling approaches have demonstrated up to 75% reduction in hazardous air pollutants compared to virgin production pathways.

Energy efficiency metrics indicate that upcycled hydrocarbon production typically consumes 40-55% less energy than conventional processes, though this varies significantly based on feedstock quality and specific conversion technologies employed. The integration of renewable energy sources into upcycling operations can further enhance this environmental benefit.

Toxicity profiles of upcycled products show comparable or improved safety characteristics relative to virgin materials, provided that appropriate purification and quality control measures are implemented. Emerging analytical techniques now allow for comprehensive characterization of potential contaminants at parts-per-billion levels, ensuring environmental and human health protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!