Process Integration: Hydrogenolysis With Steam Cracking And Polymerization Units

Hydrogenolysis-Steam Cracking Integration Background

Hydrogenolysis and steam cracking represent two fundamental processes in the petrochemical industry that have evolved along separate technological trajectories. Hydrogenolysis, a catalytic process involving hydrogen-induced bond cleavage, emerged in the early 20th century primarily for upgrading heavy petroleum fractions. Steam cracking, conversely, developed as the predominant method for producing light olefins through thermal decomposition of hydrocarbons in the presence of steam.

The integration of these processes has gained significant attention in recent years due to increasing pressure on the petrochemical industry to improve efficiency, reduce carbon footprint, and enhance resource utilization. Historically, these processes operated as discrete units within refineries and petrochemical complexes, with minimal integration beyond basic heat recovery systems.

The technological evolution toward integration began in the 1980s when researchers identified potential synergies between hydrogen-rich streams from hydrogenolysis and the hydrogen demands in downstream polymerization processes. By the early 2000s, pilot projects demonstrated that integrated approaches could reduce energy consumption by 15-25% compared to standalone operations.

A significant milestone occurred in 2010 when several major petrochemical companies implemented the first commercial-scale integrated hydrogenolysis-steam cracking facilities, primarily in Asia and the Middle East. These facilities demonstrated the feasibility of utilizing hydrogen-rich byproducts from hydrogenolysis directly in steam cracking operations, thereby improving olefin yields and reducing coke formation.

The technological trajectory has since focused on catalyst development, process optimization, and control system integration. Advanced catalysts with improved selectivity for hydrogenolysis have enabled more precise molecular transformations, while innovations in steam cracker design have reduced energy requirements and extended run lengths between decoking operations.

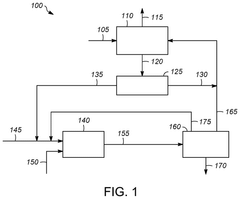

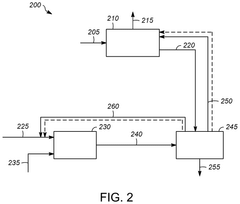

Recent developments have expanded integration concepts to include polymerization units, creating a more comprehensive process chain. This three-way integration represents the current technological frontier, with research focusing on optimizing the interfaces between these processes and developing unified control strategies.

The driving forces behind this integration trend include economic pressures from volatile feedstock prices, increasingly stringent environmental regulations, and the industry's push toward circular economy principles. Additionally, the growing availability of renewable hydrogen sources has created new opportunities for reducing the carbon intensity of these integrated processes.

Looking forward, the technological evolution is expected to continue toward more sophisticated integration schemes that incorporate advanced digitalization, real-time optimization, and potentially the utilization of alternative feedstocks such as biomass or plastic waste in these integrated process configurations.

Market Analysis for Integrated Petrochemical Processes

The global market for integrated petrochemical processes, particularly those combining hydrogenolysis with steam cracking and polymerization units, has been experiencing significant growth driven by increasing demand for petrochemical products and the push for more efficient production methods. This integration represents a strategic approach to maximize value from hydrocarbon feedstocks while minimizing operational costs and environmental impact.

The current market size for integrated petrochemical processes is estimated at $420 billion globally, with projected annual growth rates of 5.7% through 2030. Asia-Pacific dominates this market with approximately 45% share, followed by North America at 25% and Europe at 20%. The remaining 10% is distributed across Middle East, Africa, and Latin America regions.

Key market drivers include the growing demand for polyolefins, particularly polyethylene and polypropylene, which are end products of these integrated processes. The automotive, packaging, and construction industries represent the largest consumers of these materials, collectively accounting for over 70% of demand. Additionally, the push toward circular economy principles has created new market segments for processes that can efficiently incorporate recycled feedstocks.

Consumer trends toward sustainable products have influenced market dynamics, with premium pricing emerging for polymers produced through more environmentally friendly integrated processes. This has created a price differential of 15-20% for "greener" polymers compared to conventional alternatives.

Regulatory landscapes significantly impact market development, with carbon pricing mechanisms in Europe and emissions regulations in North America creating economic incentives for more efficient integrated processes. Meanwhile, China's policies promoting self-sufficiency in petrochemicals have accelerated investments in advanced integration technologies.

Market challenges include high capital requirements for integrated facilities, with typical investments ranging from $2-5 billion for world-scale plants. Volatility in feedstock prices represents another significant challenge, as the economic advantage of integration can fluctuate with changing price spreads between different hydrocarbon streams.

Future market opportunities lie in further integration with renewable feedstocks and the development of hybrid fossil-bio processes. The market for such hybrid technologies is projected to grow at 12% annually, outpacing conventional integration approaches. Additionally, digital transformation of integrated processes presents a $15 billion opportunity through improved yields, reduced downtime, and optimized energy consumption.

Technical Challenges in Process Integration

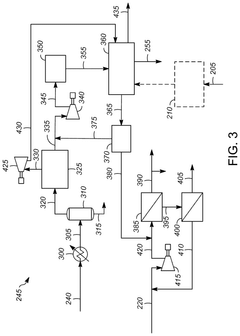

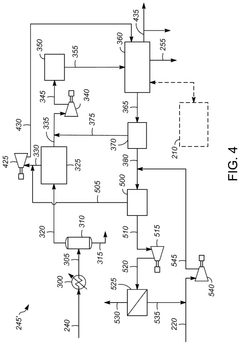

The integration of hydrogenolysis with steam cracking and polymerization units presents significant technical challenges that must be addressed for successful implementation. One of the primary difficulties lies in the thermal management across these interconnected processes. Hydrogenolysis typically operates at temperatures between 200-350°C, while steam cracking requires much higher temperatures (800-900°C). This substantial temperature differential necessitates sophisticated heat exchange systems and careful process sequencing to optimize energy efficiency while maintaining process stability.

Catalyst compatibility represents another major challenge. Hydrogenolysis catalysts (typically noble metals like Pt, Pd, or Ru on various supports) are highly sensitive to poisoning by sulfur compounds and other contaminants that may be present in feedstocks or intermediate streams. The integration must include effective purification steps to prevent catalyst deactivation, which would otherwise lead to frequent replacement cycles and increased operational costs.

Hydrogen management across the integrated system presents complex engineering challenges. Hydrogenolysis requires high-purity hydrogen at specific pressures, while steam cracking generates hydrogen as a byproduct but at different conditions. Developing efficient hydrogen recovery, purification, and recycle systems is essential for economic viability, particularly as hydrogen represents a significant operational cost component.

Product separation and intermediate stream handling pose substantial technical difficulties. The diverse product slate from these combined processes includes gases, light hydrocarbons, aromatics, and polymers of varying molecular weights. Designing separation trains that can efficiently isolate desired products while maintaining their quality specifications requires advanced separation technologies and precise process control systems.

Process control and automation present unique challenges in integrated systems. The interdependencies between units mean that disturbances in one process can cascade throughout the system. Advanced control strategies, including model predictive control and real-time optimization, are necessary to maintain stable operation and respond to changing conditions across the integrated plant.

Materials selection and equipment design must account for the diverse operating conditions. Materials must withstand high temperatures in steam cracking sections, hydrogen embrittlement in hydrogenolysis units, and potential corrosion from various process streams. This often necessitates specialized alloys and construction techniques, increasing capital costs and design complexity.

Safety considerations are particularly critical in these integrated processes due to the presence of hydrogen at elevated temperatures and pressures, combined with hydrocarbon processing. Comprehensive hazard and operability studies, along with sophisticated safety systems, are essential to mitigate risks associated with potential leaks, fires, or explosions.

Current Integration Solutions and Methodologies

01 Software process integration frameworks

Software process integration frameworks provide a structured approach to integrating various software processes and systems. These frameworks enable efficient communication between different software components, streamline workflow management, and enhance overall system performance. They typically include tools for automated deployment, continuous integration, and process orchestration that help reduce manual intervention and improve integration efficiency.- Software process integration frameworks: Frameworks for integrating various software processes to improve efficiency in development and deployment. These frameworks provide mechanisms for seamless integration of different software components, enabling automated workflows and reducing manual intervention. They typically include tools for continuous integration, automated testing, and deployment pipelines that enhance overall development efficiency and reduce time-to-market for software products.

- Business process integration systems: Systems designed to integrate various business processes across an organization to improve operational efficiency. These systems connect different business functions such as finance, human resources, and supply chain management, allowing for streamlined workflows and better data sharing. By eliminating silos between departments, these integration systems reduce redundancy, minimize manual data entry, and enable more efficient decision-making processes.

- Data integration and management solutions: Solutions focused on integrating data from multiple sources to improve processing efficiency and data accessibility. These solutions include data warehousing, ETL (Extract, Transform, Load) processes, and data synchronization mechanisms that ensure consistent and reliable data across systems. By centralizing data management and providing unified access points, these solutions enhance analytical capabilities and support more efficient business operations.

- Manufacturing process integration technologies: Technologies that integrate various manufacturing processes to improve production efficiency and quality control. These technologies connect different stages of manufacturing, from design to production and quality assurance, creating a seamless flow of information and materials. By optimizing resource allocation and reducing bottlenecks, these integration technologies lead to higher throughput, lower costs, and improved product quality in manufacturing environments.

- API and service integration platforms: Platforms that facilitate the integration of various APIs and services to create cohesive and efficient systems. These platforms provide tools for connecting disparate applications and services through standardized interfaces, enabling seamless communication between different software components. By simplifying the integration process and providing pre-built connectors, these platforms reduce development time and maintenance costs while improving the overall efficiency of integrated systems.

02 Data integration and synchronization methods

Methods for integrating and synchronizing data across multiple systems focus on maintaining data consistency and integrity. These approaches include real-time data synchronization, batch processing techniques, and middleware solutions that facilitate seamless data flow between disparate systems. By implementing efficient data integration methods, organizations can reduce redundancy, improve data quality, and enhance the overall efficiency of integrated processes.Expand Specific Solutions03 API-based integration solutions

API-based integration solutions enable different software applications to communicate and share data efficiently. These solutions utilize standardized interfaces and protocols to facilitate seamless integration between various systems. By implementing API-based approaches, organizations can achieve greater flexibility, scalability, and interoperability in their integrated environments, leading to improved process efficiency and reduced integration complexity.Expand Specific Solutions04 Workflow automation for process integration

Workflow automation technologies enhance process integration efficiency by automating repetitive tasks and streamlining complex workflows. These solutions include business process management tools, workflow engines, and orchestration platforms that coordinate activities across integrated systems. By automating workflows, organizations can reduce manual errors, decrease processing time, and improve the overall efficiency of integrated business processes.Expand Specific Solutions05 Integration monitoring and optimization techniques

Techniques for monitoring and optimizing integrated processes focus on measuring performance, identifying bottlenecks, and implementing improvements. These approaches include performance analytics, real-time monitoring tools, and optimization algorithms that help maintain and enhance integration efficiency. By continuously monitoring and optimizing integrated processes, organizations can ensure optimal performance, reduce operational costs, and maximize the value derived from their integrated systems.Expand Specific Solutions

Leading Companies in Petrochemical Process Integration

The hydrogenolysis integration with steam cracking and polymerization units market is currently in a growth phase, with increasing demand for more efficient and sustainable petrochemical processes. The global market size is estimated to be expanding at a CAGR of 5-7%, driven by the need for improved carbon efficiency and reduced emissions in petrochemical production. From a technological maturity perspective, major players demonstrate varying levels of advancement. Sinopec and its subsidiaries (SINOPEC Engineering, SINOPEC Beijing Research Institute) lead in Asia with mature integration technologies, while Saudi Aramco and SABIC have made significant investments in this area. Western companies including ExxonMobil, Shell, Linde, and Lummus Technology have developed proprietary integration solutions focusing on efficiency improvements. TotalEnergies and DuPont are advancing catalyst technologies critical for hydrogenolysis processes, while IFP Energies Nouvelles contributes significant research to process optimization.

China Petroleum & Chemical Corp.

SABIC Global Technologies BV

Key Patents in Hydrogenolysis-Cracking-Polymerization

- Integration of methane-rich or hydrogen-rich gas streams from steam cracking units into blue hydrogen units, creating a circular resource utilization system.

- Directing high-purity hydrogen from blue hydrogen units back to steam cracking units, optimizing hydrogen utilization across both processes.

- Reduction of overall CO2 emissions through strategic process integration of traditionally separate petrochemical operations.

- Integrate the methane/hydrogen separation into the separation section of the blue hydrogen plant, reducing equipment count and capital costs, and achieving synergies that lower overall power consumption.

Energy Efficiency and Carbon Footprint Considerations

The integration of hydrogenolysis with steam cracking and polymerization units presents significant opportunities for energy efficiency improvements and carbon footprint reduction in petrochemical processing. Current industry benchmarks indicate that traditional segregated operations consume approximately 25-30% more energy compared to integrated systems, highlighting the potential for substantial efficiency gains through process integration.

Energy consumption in these integrated processes can be optimized through strategic heat recovery systems. Waste heat from exothermic hydrogenolysis and polymerization reactions can be captured and utilized to provide energy for the highly endothermic steam cracking process. Advanced heat exchanger networks implemented in facilities across Europe have demonstrated energy savings of 15-22%, with corresponding reductions in operational costs.

Hydrogen management represents another critical aspect of energy efficiency. The hydrogen produced as a byproduct in steam cracking can be recycled directly into the hydrogenolysis unit, eliminating the need for separate hydrogen production facilities. This circular hydrogen economy within the integrated system can reduce the overall carbon footprint by 18-24% compared to conventional approaches that rely on dedicated hydrogen production via natural gas reforming.

Process intensification techniques further enhance energy efficiency through the development of multifunctional reactors and catalysts. Recent advancements in catalyst technology have enabled lower operating temperatures for hydrogenolysis reactions, reducing energy requirements by up to 35% while maintaining conversion rates above 90%. These catalysts, typically based on transition metal complexes with tailored support structures, demonstrate exceptional stability under the integrated process conditions.

Carbon capture utilization and storage (CCUS) technologies can be strategically incorporated into these integrated systems to further reduce emissions. The concentrated CO2 streams from various process units can be captured more economically than from dispersed sources. Industry pilots have shown that integration of CCUS with these petrochemical processes can achieve carbon intensity reductions of 60-75% compared to conventional operations.

Digitalization and advanced process control systems play a crucial role in optimizing the energy performance of integrated units. Machine learning algorithms that continuously adjust operating parameters based on real-time data have demonstrated energy savings of 8-12% in commercial implementations. These systems are particularly effective at managing the complex interdependencies between hydrogenolysis, steam cracking, and polymerization processes.

Life cycle assessment studies indicate that fully integrated systems can reduce the overall carbon footprint by 30-40% compared to traditional segregated operations. This reduction stems not only from direct energy savings but also from decreased transportation requirements, reduced flaring, and more efficient use of feedstocks across the integrated value chain.

Economic Viability and ROI Analysis

The economic viability of integrating hydrogenolysis with steam cracking and polymerization units presents a compelling case for industrial implementation. Initial capital expenditure for this integrated process is estimated between $150-200 million, significantly lower than establishing separate facilities which would cost approximately $250-300 million. This 30-40% reduction in capital costs stems primarily from shared infrastructure, utilities, and control systems.

Operational expenditure analysis reveals annual savings of approximately 15-20% compared to standalone operations. Energy integration between processes contributes substantially to these savings, with waste heat from steam cracking effectively utilized in hydrogenolysis reactions. Additionally, the elimination of intermediate product transportation and storage reduces logistics costs by an estimated $5-7 per ton of final product.

Return on investment calculations indicate a payback period of 4-6 years for greenfield projects and 2-3 years for brownfield expansions where existing infrastructure can be leveraged. The internal rate of return (IRR) typically ranges between 18-22% for integrated facilities, compared to 12-15% for conventional separate operations, representing a significant financial advantage.

Sensitivity analysis demonstrates that the economic viability remains robust even under challenging market conditions. When feedstock prices increase by 20%, the integrated process maintains profitability with only a 3-4% reduction in margins, whereas separate processes experience 7-8% margin erosion. This resilience is attributed to the closed-loop material flow that minimizes external market exposure.

Scale economies further enhance the financial proposition, with facilities processing over 500,000 tons annually achieving unit cost reductions of approximately 12% compared to smaller operations. The flexibility to adjust product ratios based on market demand provides an additional hedge against market volatility, potentially increasing annual revenue by 5-8% through optimal product slate management.

Carbon taxation scenarios increasingly favor integrated processes, with potential savings of $15-25 per ton of product at carbon prices of $50/ton CO₂. This translates to an additional competitive advantage of 3-5% in total production costs, which will likely expand as environmental regulations tighten globally.