How to Integrate Circular Economy Approaches in Cellophane?

Cellophane Circular Economy Background and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and industrial applications for over a century. As global concerns about environmental sustainability and resource depletion grow, the integration of circular economy approaches in cellophane production and usage has become increasingly crucial. This technological evolution aims to transform the linear "take-make-dispose" model into a circular system that maximizes resource efficiency and minimizes waste.

The circular economy concept, when applied to cellophane, encompasses the entire lifecycle of the material, from raw material sourcing to end-of-life management. The primary objective is to create a closed-loop system where cellophane products are designed for durability, reusability, and recyclability. This approach not only reduces environmental impact but also presents opportunities for innovation and economic growth within the industry.

Historically, cellophane production has relied heavily on wood pulp as its primary raw material. However, the circular economy paradigm challenges this traditional method by exploring alternative, renewable sources of cellulose, such as agricultural waste or fast-growing plants. This shift aims to reduce pressure on forest resources and create a more sustainable supply chain for cellophane manufacturing.

Another key aspect of integrating circular economy principles into cellophane production is the optimization of manufacturing processes to minimize energy consumption and waste generation. This includes developing more efficient methods for cellulose regeneration, implementing closed-loop water systems, and utilizing renewable energy sources in production facilities.

The end-of-life management of cellophane products is a critical component of the circular economy approach. Current objectives focus on enhancing the biodegradability of cellophane while also exploring innovative recycling technologies. These efforts aim to ensure that cellophane can be safely returned to the environment or efficiently reprocessed into new products, thereby closing the material loop.

Integrating circular economy approaches in cellophane also involves rethinking product design and usage patterns. This includes developing cellophane products that are easier to recycle, promoting the use of cellophane in applications where its unique properties offer sustainability advantages over alternative materials, and educating consumers and businesses about proper disposal and recycling practices.

As the cellophane industry embarks on this circular economy journey, collaboration across the value chain becomes essential. From raw material suppliers to manufacturers, retailers, and waste management companies, all stakeholders must align their efforts to create a truly circular system for cellophane. This collaborative approach is expected to drive innovation, create new business models, and ultimately lead to a more sustainable and resilient cellophane industry.

Market Analysis for Sustainable Cellophane Products

The market for sustainable cellophane products is experiencing significant growth as consumers and businesses increasingly prioritize environmentally friendly packaging solutions. This shift is driven by growing awareness of plastic pollution and the need for circular economy approaches in packaging materials. Cellophane, a biodegradable and compostable material derived from renewable resources, is well-positioned to meet this demand.

The global market for sustainable packaging, including cellophane-based products, is projected to reach substantial value in the coming years. This growth is fueled by stringent regulations on single-use plastics, consumer preferences for eco-friendly alternatives, and corporate sustainability initiatives. Major industries driving demand include food and beverage, cosmetics, and pharmaceuticals, where cellophane's barrier properties and biodegradability offer significant advantages.

Consumer surveys indicate a willingness to pay premium prices for sustainable packaging options, with a notable percentage of respondents expressing preference for biodegradable materials like cellophane. This trend is particularly strong among younger demographics and in developed markets with high environmental consciousness.

The food packaging segment represents the largest market share for sustainable cellophane products, driven by the material's excellent moisture barrier properties and compatibility with various food types. The cosmetics and personal care industry is also rapidly adopting sustainable cellophane packaging, aligning with the clean beauty movement and eco-conscious consumer preferences.

Geographically, Europe leads in sustainable cellophane adoption, followed by North America and Asia-Pacific. Developing markets in Latin America and Africa show promising growth potential as environmental regulations tighten and awareness increases.

Key market challenges include the higher cost of sustainable cellophane compared to conventional plastics and the need for improved recycling infrastructure. However, ongoing research and development efforts are focused on reducing production costs and enhancing the material's properties, which is expected to drive further market expansion.

The competitive landscape is characterized by a mix of established packaging companies and innovative startups. Major players are investing in sustainable cellophane production capabilities, while new entrants are introducing novel formulations and applications. Strategic partnerships between material suppliers, packaging manufacturers, and end-users are becoming increasingly common to drive innovation and scale production.

As circular economy principles gain traction, the market for sustainable cellophane products is poised for continued growth. The integration of recycled content, development of closed-loop systems, and advancements in composting infrastructure are expected to further enhance the material's sustainability profile and market appeal in the coming years.

Current Challenges in Cellophane Recycling and Reuse

Cellophane, a biodegradable and compostable material, faces several challenges in its recycling and reuse processes, hindering the full integration of circular economy approaches. One of the primary obstacles is the lack of widespread collection and sorting systems specifically designed for cellophane. Unlike more common plastics, cellophane is often mixed with general waste, making it difficult to isolate and process separately.

The material's properties also present challenges in recycling. Cellophane's moisture sensitivity can lead to degradation during storage and transportation, potentially compromising its quality before it reaches recycling facilities. Additionally, the presence of coatings and additives in some cellophane products complicates the recycling process, as these substances need to be removed to ensure the purity of the recycled material.

Another significant challenge is the limited infrastructure for cellophane recycling. Many recycling facilities are not equipped to handle cellophane effectively, leading to its disposal in landfills or incineration. This lack of specialized recycling technology and processes results in a substantial loss of potentially reusable material.

The economic viability of cellophane recycling also poses a challenge. The costs associated with collecting, sorting, and processing cellophane can be high compared to the value of the recycled material. This economic imbalance discourages investment in recycling infrastructure and technology, perpetuating the cycle of inadequate recycling options.

Consumer awareness and behavior present additional hurdles. Many consumers are unaware of cellophane's recyclability or proper disposal methods, leading to improper disposal and contamination of recycling streams. Education and clear labeling are crucial to address this issue and improve recycling rates.

Furthermore, the quality of recycled cellophane can be inconsistent, making it challenging to use in high-value applications. This quality variability limits the potential markets for recycled cellophane, reducing its economic value and discouraging widespread adoption of recycling practices.

Lastly, regulatory frameworks and industry standards for cellophane recycling are often lacking or inconsistent across regions. This absence of clear guidelines and incentives hampers the development of efficient recycling systems and circular economy initiatives for cellophane.

Addressing these challenges requires a multifaceted approach, involving technological innovation, infrastructure development, economic incentives, consumer education, and supportive policies to create a more robust circular economy for cellophane.

Existing Circular Economy Solutions for Cellophane

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, where it can help preserve freshness and extend shelf life. Cellophane can be used alone or in combination with other materials to create various packaging solutions.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is commonly employed in food packaging, gift wrapping, and industrial packaging solutions. The material's ability to protect products while allowing visibility makes it a popular choice in various industries.

- Biodegradable cellophane alternatives: Research and development efforts are focused on creating biodegradable alternatives to traditional cellophane. These eco-friendly options aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area include the use of plant-based materials and modified production processes to enhance biodegradability.

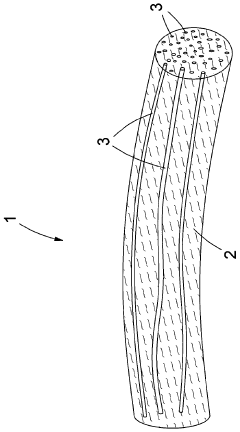

- Cellophane in textile and fiber applications: Cellophane finds applications in the textile and fiber industry. It can be used to create unique fabric finishes, as a component in composite materials, or as a protective layer in textile manufacturing processes. The material's properties allow for innovative applications in fashion and technical textiles.

- Modified cellophane for enhanced functionality: Researchers are developing modified cellophane materials with enhanced properties such as improved barrier characteristics, antimicrobial properties, or increased strength. These modifications aim to expand the range of applications for cellophane and improve its performance in existing uses.

- Cellophane in food preservation and storage: Cellophane plays a significant role in food preservation and storage solutions. Its properties make it suitable for extending the shelf life of various food products while maintaining freshness. Innovations in this area focus on improving the material's barrier properties against moisture and gases, as well as enhancing its compatibility with different food types.

02 Biodegradable cellophane alternatives

Research is being conducted to develop biodegradable alternatives to traditional cellophane. These new materials aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area often involve the use of plant-based or other renewable resources to create sustainable packaging solutions.Expand Specific Solutions03 Cellophane in textile and fiber applications

Cellophane and related materials are used in various textile and fiber applications. This includes the production of regenerated cellulose fibers, which can be used to create fabrics with unique properties. The use of cellophane in textiles can provide benefits such as moisture management and improved durability.Expand Specific Solutions04 Cellophane production and processing techniques

Advancements in cellophane production and processing techniques aim to improve the material's properties and efficiency of manufacture. This includes innovations in the regeneration of cellulose, surface treatments, and the incorporation of additives to enhance specific characteristics of the cellophane.Expand Specific Solutions05 Cellophane in medical and pharmaceutical applications

Cellophane and its derivatives find applications in medical and pharmaceutical fields. This includes use in drug delivery systems, wound dressings, and as a component in various medical devices. The biocompatibility and barrier properties of cellophane make it suitable for these specialized applications.Expand Specific Solutions

Key Players in Sustainable Cellophane Production

The integration of circular economy approaches in cellophane production is at an early stage of development, with the market still relatively small but growing. The technology's maturity varies among key players, with companies like Danisco US, Inc. and Kolon Industries, Inc. leading in research and development. Saint-Gobain Isover G+H AG and DuPont de Nemours, Inc. are also making significant strides in sustainable materials. Academic institutions such as Politecnico di Milano and the University of Leeds are contributing to advancing the technology through collaborative research efforts. As environmental concerns grow, this field is expected to expand, driven by increasing demand for sustainable packaging solutions.

Evrnu, Inc.

University of Leeds

Innovative Approaches to Cellophane Circularity

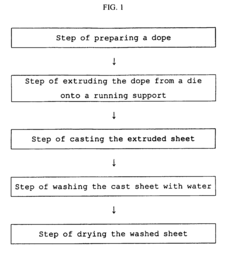

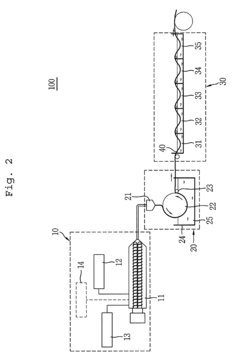

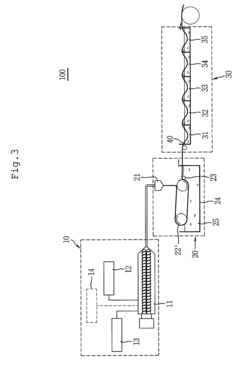

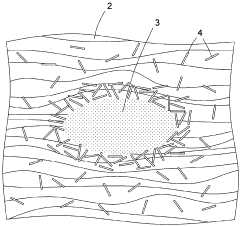

- A method involving the preparation of a dope from alpha-cellulose pulp and an aqueous N-methylmorpholine-N-oxide solution, extrusion, casting, washing, and drying, which omits the use of NaOH or H2SO4 and avoids the use of CS2, allowing for the production of an environmentally friendly cellulose-based film with excellent properties.

- A method involving the preparation of an emulsion with non-polar organic compounds in a cellulose solution, stabilized by hydrophobic viscosity-increasing agents and nanoscale particles, which are then recrystallized to create cellulose matrix-based molded bodies with dispersed non-polar organic compounds, allowing for controlled release of active ingredients.

Environmental Impact Assessment of Circular Cellophane

The environmental impact assessment of circular cellophane is a crucial step in integrating circular economy approaches into cellophane production and usage. This assessment evaluates the potential environmental effects throughout the entire lifecycle of cellophane, from raw material extraction to disposal or recycling.

Circular cellophane production aims to minimize waste and maximize resource efficiency. The assessment begins by examining the sourcing of raw materials, primarily cellulose from wood pulp or cotton linters. Sustainable forestry practices and responsible cotton cultivation are essential to reduce deforestation and soil degradation. The manufacturing process is then scrutinized, focusing on energy consumption, water usage, and chemical emissions. Circular approaches in this stage may include implementing closed-loop systems for water and solvent recovery, as well as utilizing renewable energy sources to power production facilities.

The use phase of cellophane products is evaluated for their potential environmental impacts, such as biodegradability and compostability. Circular cellophane designs prioritize materials that can safely decompose in natural environments or industrial composting facilities, reducing long-term environmental pollution. The assessment also considers the product's ability to replace less environmentally friendly alternatives, potentially leading to net positive impacts.

End-of-life management is a critical aspect of the circular economy approach for cellophane. The assessment examines the feasibility and environmental implications of various disposal methods, including recycling, composting, and energy recovery. Recycling cellophane can significantly reduce the demand for virgin materials and associated environmental impacts. However, the assessment must consider the energy and resources required for collection, sorting, and reprocessing.

Life Cycle Assessment (LCA) methodologies are employed to quantify the environmental impacts across different categories, such as global warming potential, water consumption, and ecotoxicity. These assessments help identify hotspots in the circular cellophane lifecycle where environmental improvements can be made. Additionally, the assessment evaluates the potential for cascading use, where cellophane products or their components can be repurposed for different applications before final disposal.

The environmental impact assessment also considers the broader systemic effects of transitioning to circular cellophane. This includes potential changes in transportation and logistics, shifts in consumer behavior, and the development of new recycling infrastructure. By comprehensively evaluating these factors, the assessment provides valuable insights for policymakers, manufacturers, and consumers to make informed decisions that support the integration of circular economy principles in the cellophane industry.

Policy Framework for Circular Economy in Packaging

The policy framework for circular economy in packaging is a critical component in the integration of circular economy approaches in cellophane production and use. Governments worldwide are increasingly recognizing the need for comprehensive policies to support the transition towards a more sustainable and circular packaging industry. These policies typically encompass a range of measures, including regulatory instruments, economic incentives, and voluntary agreements.

At the regulatory level, many countries have implemented extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their packaging products, including collection and recycling. For cellophane, this could involve setting up collection systems and investing in recycling infrastructure. Additionally, some jurisdictions have introduced bans or restrictions on certain single-use plastic items, which may indirectly affect cellophane usage and drive innovation towards more sustainable alternatives.

Economic instruments play a crucial role in shaping market behavior. These may include taxes on virgin materials, subsidies for recycled content, or deposit-refund systems for packaging. Such measures can create financial incentives for businesses to adopt circular approaches in cellophane production and use, encouraging the development of closed-loop systems and the use of recycled materials.

Voluntary agreements and industry standards also form an important part of the policy framework. These can include commitments to reduce packaging waste, increase recycled content, or improve recyclability. For cellophane, this might involve industry-wide targets for biodegradability or compostability, as well as standardization of labeling to facilitate proper disposal and recycling.

Research and development support is another key aspect of the policy framework. Governments often provide funding or tax incentives for companies investing in circular economy innovations. This could be particularly relevant for cellophane, as there is a need for technological advancements to improve its recyclability and biodegradability while maintaining its functional properties.

Public procurement policies can also drive the adoption of circular economy principles in packaging. By prioritizing products with recycled content or those designed for easy recycling, governments can create a significant market pull for circular cellophane solutions. This approach can help scale up innovative technologies and business models in the cellophane industry.

Education and awareness campaigns form an integral part of the policy framework, aiming to inform consumers about proper disposal and recycling of cellophane packaging. These initiatives can help increase participation in recycling programs and reduce contamination in waste streams, which is crucial for the effective recycling of cellophane materials.