Key Techniques in Stretchable Cellophane Innovation

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Stretchable Cellophane Evolution and Objectives

Stretchable cellophane has emerged as a revolutionary material in the packaging industry, offering enhanced flexibility and durability compared to traditional cellophane. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to improve the mechanical properties of conventional cellophane.

The primary objective of stretchable cellophane innovation is to develop a material that combines the transparency and biodegradability of traditional cellophane with improved elasticity and strength. This goal addresses the growing demand for sustainable packaging solutions that can withstand various environmental stresses and maintain product integrity during transportation and storage.

Over the past two decades, significant advancements have been made in the field of stretchable cellophane. Initial efforts focused on modifying the cellulose structure through chemical treatments and the incorporation of plasticizers. These early attempts yielded modest improvements in flexibility but often compromised other desirable properties such as transparency and barrier performance.

A major breakthrough came with the introduction of nanocomposite technology in the mid-2010s. By incorporating nanoscale reinforcements, such as cellulose nanofibrils or graphene oxide, researchers were able to significantly enhance the mechanical properties of cellophane without sacrificing its inherent benefits. This approach opened up new possibilities for creating highly stretchable and resilient cellophane films.

Recent developments have focused on optimizing the production processes and exploring novel bio-based additives to further improve the performance of stretchable cellophane. The integration of advanced manufacturing techniques, such as electrospinning and 3D printing, has enabled the creation of complex structures and tailored properties at the microscale level.

Looking ahead, the future objectives for stretchable cellophane innovation include achieving even greater elasticity and tear resistance while maintaining or improving its barrier properties against moisture and gases. There is also a growing emphasis on developing fully biodegradable formulations that can decompose rapidly in various environmental conditions without leaving harmful residues.

Another key goal is to scale up production processes to make stretchable cellophane economically viable for widespread commercial adoption. This involves optimizing raw material sourcing, refining manufacturing techniques, and reducing overall production costs to compete with conventional packaging materials.

As environmental concerns continue to drive innovation in the packaging industry, stretchable cellophane is poised to play a crucial role in the transition towards more sustainable and functional packaging solutions. The ongoing research and development efforts aim to position this material as a versatile and eco-friendly alternative to traditional plastic films, catering to the evolving needs of consumers and businesses alike.

The primary objective of stretchable cellophane innovation is to develop a material that combines the transparency and biodegradability of traditional cellophane with improved elasticity and strength. This goal addresses the growing demand for sustainable packaging solutions that can withstand various environmental stresses and maintain product integrity during transportation and storage.

Over the past two decades, significant advancements have been made in the field of stretchable cellophane. Initial efforts focused on modifying the cellulose structure through chemical treatments and the incorporation of plasticizers. These early attempts yielded modest improvements in flexibility but often compromised other desirable properties such as transparency and barrier performance.

A major breakthrough came with the introduction of nanocomposite technology in the mid-2010s. By incorporating nanoscale reinforcements, such as cellulose nanofibrils or graphene oxide, researchers were able to significantly enhance the mechanical properties of cellophane without sacrificing its inherent benefits. This approach opened up new possibilities for creating highly stretchable and resilient cellophane films.

Recent developments have focused on optimizing the production processes and exploring novel bio-based additives to further improve the performance of stretchable cellophane. The integration of advanced manufacturing techniques, such as electrospinning and 3D printing, has enabled the creation of complex structures and tailored properties at the microscale level.

Looking ahead, the future objectives for stretchable cellophane innovation include achieving even greater elasticity and tear resistance while maintaining or improving its barrier properties against moisture and gases. There is also a growing emphasis on developing fully biodegradable formulations that can decompose rapidly in various environmental conditions without leaving harmful residues.

Another key goal is to scale up production processes to make stretchable cellophane economically viable for widespread commercial adoption. This involves optimizing raw material sourcing, refining manufacturing techniques, and reducing overall production costs to compete with conventional packaging materials.

As environmental concerns continue to drive innovation in the packaging industry, stretchable cellophane is poised to play a crucial role in the transition towards more sustainable and functional packaging solutions. The ongoing research and development efforts aim to position this material as a versatile and eco-friendly alternative to traditional plastic films, catering to the evolving needs of consumers and businesses alike.

Market Analysis for Flexible Packaging Solutions

The flexible packaging market has experienced significant growth in recent years, driven by increasing consumer demand for convenience, sustainability, and extended shelf life of products. This trend is particularly evident in the food and beverage industry, where stretchable cellophane innovations are gaining traction. The global flexible packaging market was valued at $252.4 billion in 2022 and is projected to reach $360.8 billion by 2028, growing at a CAGR of 6.2% during the forecast period.

Stretchable cellophane, as a key component of flexible packaging solutions, offers numerous advantages over traditional rigid packaging materials. Its ability to conform to various shapes and sizes while maintaining product integrity has made it increasingly popular among manufacturers and consumers alike. The food packaging segment dominates the flexible packaging market, accounting for approximately 70% of the total market share.

The Asia-Pacific region leads the flexible packaging market, with China and India being the major contributors to growth. This can be attributed to rapid urbanization, changing lifestyles, and increasing disposable incomes in these countries. North America and Europe follow closely, with mature markets focusing on sustainable and eco-friendly packaging solutions.

Consumer preferences are shifting towards packaging that is not only functional but also environmentally responsible. This has led to increased research and development in biodegradable and compostable stretchable cellophane materials. The sustainable packaging segment within the flexible packaging market is expected to grow at a CAGR of 7.5% from 2023 to 2028.

Key players in the flexible packaging market are investing heavily in stretchable cellophane innovation to gain a competitive edge. Companies like Amcor, Berry Global, and Sealed Air Corporation are at the forefront of developing advanced flexible packaging solutions. These companies are focusing on improving the barrier properties, recyclability, and overall performance of stretchable cellophane to meet evolving market demands.

The e-commerce boom has further accelerated the demand for flexible packaging solutions, including stretchable cellophane. As online retail continues to grow, the need for lightweight, durable, and cost-effective packaging materials has become paramount. This trend is expected to drive further innovation in stretchable cellophane technology, with a focus on enhancing its protective properties and reducing environmental impact.

In conclusion, the market analysis for flexible packaging solutions, particularly stretchable cellophane innovations, indicates a robust growth trajectory. The industry is poised for continued expansion, driven by technological advancements, changing consumer preferences, and the need for sustainable packaging options. As the market evolves, companies that can successfully innovate and adapt to these trends will likely emerge as leaders in the flexible packaging space.

Stretchable cellophane, as a key component of flexible packaging solutions, offers numerous advantages over traditional rigid packaging materials. Its ability to conform to various shapes and sizes while maintaining product integrity has made it increasingly popular among manufacturers and consumers alike. The food packaging segment dominates the flexible packaging market, accounting for approximately 70% of the total market share.

The Asia-Pacific region leads the flexible packaging market, with China and India being the major contributors to growth. This can be attributed to rapid urbanization, changing lifestyles, and increasing disposable incomes in these countries. North America and Europe follow closely, with mature markets focusing on sustainable and eco-friendly packaging solutions.

Consumer preferences are shifting towards packaging that is not only functional but also environmentally responsible. This has led to increased research and development in biodegradable and compostable stretchable cellophane materials. The sustainable packaging segment within the flexible packaging market is expected to grow at a CAGR of 7.5% from 2023 to 2028.

Key players in the flexible packaging market are investing heavily in stretchable cellophane innovation to gain a competitive edge. Companies like Amcor, Berry Global, and Sealed Air Corporation are at the forefront of developing advanced flexible packaging solutions. These companies are focusing on improving the barrier properties, recyclability, and overall performance of stretchable cellophane to meet evolving market demands.

The e-commerce boom has further accelerated the demand for flexible packaging solutions, including stretchable cellophane. As online retail continues to grow, the need for lightweight, durable, and cost-effective packaging materials has become paramount. This trend is expected to drive further innovation in stretchable cellophane technology, with a focus on enhancing its protective properties and reducing environmental impact.

In conclusion, the market analysis for flexible packaging solutions, particularly stretchable cellophane innovations, indicates a robust growth trajectory. The industry is poised for continued expansion, driven by technological advancements, changing consumer preferences, and the need for sustainable packaging options. As the market evolves, companies that can successfully innovate and adapt to these trends will likely emerge as leaders in the flexible packaging space.

Current Challenges in Stretchable Cellophane Development

The development of stretchable cellophane faces several significant challenges that hinder its widespread adoption and commercialization. One of the primary obstacles is achieving a balance between stretchability and mechanical strength. While increasing the material's elasticity is crucial for its stretchable properties, it often comes at the cost of reduced tensile strength and tear resistance, limiting its practical applications.

Another major challenge lies in maintaining the optical clarity and transparency of cellophane when incorporating stretchable properties. Traditional methods of enhancing flexibility, such as adding plasticizers or modifying the cellulose structure, can lead to increased haziness or reduced light transmission, compromising the material's visual appeal and functionality in packaging applications.

The durability and longevity of stretchable cellophane under repeated stretching and relaxation cycles pose a significant hurdle. Fatigue resistance and the ability to maintain consistent performance over time are critical factors that require further improvement. Current iterations of stretchable cellophane often suffer from degradation in mechanical properties after multiple stretching cycles, limiting their long-term usability.

Environmental concerns and sustainability requirements present additional challenges in stretchable cellophane development. As the demand for eco-friendly packaging solutions grows, researchers must find ways to create stretchable cellophane that is both biodegradable and recyclable without compromising its performance characteristics. This involves developing new production processes and formulations that minimize environmental impact while maintaining the desired stretchable properties.

The scalability of production processes for stretchable cellophane remains a significant challenge. Current laboratory-scale techniques for enhancing cellophane's stretchability are often difficult to translate into large-scale manufacturing operations. Developing cost-effective and efficient production methods that can meet industrial demand while maintaining consistent quality and performance is crucial for the commercial viability of stretchable cellophane.

Adhesion and compatibility issues with other materials in multi-layer packaging structures present another set of challenges. Stretchable cellophane must be able to bond effectively with other layers and maintain its integrity during stretching and use. Developing suitable adhesives and bonding techniques that can accommodate the material's elastic properties without compromising its performance or appearance is an ongoing area of research and development.

Lastly, regulatory compliance and food safety considerations pose additional hurdles in the development of stretchable cellophane, particularly for food packaging applications. Ensuring that the material meets stringent safety standards and does not leach harmful substances when in contact with food products is critical. This requires extensive testing and validation processes, which can be time-consuming and costly, potentially slowing down the innovation and commercialization of new stretchable cellophane products.

Another major challenge lies in maintaining the optical clarity and transparency of cellophane when incorporating stretchable properties. Traditional methods of enhancing flexibility, such as adding plasticizers or modifying the cellulose structure, can lead to increased haziness or reduced light transmission, compromising the material's visual appeal and functionality in packaging applications.

The durability and longevity of stretchable cellophane under repeated stretching and relaxation cycles pose a significant hurdle. Fatigue resistance and the ability to maintain consistent performance over time are critical factors that require further improvement. Current iterations of stretchable cellophane often suffer from degradation in mechanical properties after multiple stretching cycles, limiting their long-term usability.

Environmental concerns and sustainability requirements present additional challenges in stretchable cellophane development. As the demand for eco-friendly packaging solutions grows, researchers must find ways to create stretchable cellophane that is both biodegradable and recyclable without compromising its performance characteristics. This involves developing new production processes and formulations that minimize environmental impact while maintaining the desired stretchable properties.

The scalability of production processes for stretchable cellophane remains a significant challenge. Current laboratory-scale techniques for enhancing cellophane's stretchability are often difficult to translate into large-scale manufacturing operations. Developing cost-effective and efficient production methods that can meet industrial demand while maintaining consistent quality and performance is crucial for the commercial viability of stretchable cellophane.

Adhesion and compatibility issues with other materials in multi-layer packaging structures present another set of challenges. Stretchable cellophane must be able to bond effectively with other layers and maintain its integrity during stretching and use. Developing suitable adhesives and bonding techniques that can accommodate the material's elastic properties without compromising its performance or appearance is an ongoing area of research and development.

Lastly, regulatory compliance and food safety considerations pose additional hurdles in the development of stretchable cellophane, particularly for food packaging applications. Ensuring that the material meets stringent safety standards and does not leach harmful substances when in contact with food products is critical. This requires extensive testing and validation processes, which can be time-consuming and costly, potentially slowing down the innovation and commercialization of new stretchable cellophane products.

State-of-the-Art Stretchable Cellophane Technologies

01 Stretchable cellophane composition

Development of cellophane compositions with enhanced stretchability through the incorporation of specific additives or modifications to the cellulose structure. These compositions aim to improve the flexibility and elongation properties of cellophane while maintaining its other desirable characteristics.- Stretchable cellophane composition: Development of cellophane compositions with enhanced stretchability through the incorporation of specific additives or modifications to the cellulose structure. These compositions aim to improve the flexibility and elongation properties of cellophane while maintaining its other desirable characteristics.

- Manufacturing processes for stretchable cellophane: Innovative manufacturing techniques and processes designed to produce cellophane with increased stretchability. These methods may involve modifications to traditional cellophane production processes, such as adjustments in the casting or treatment stages, to enhance the material's elastic properties.

- Applications of stretchable cellophane: Exploration of various applications for stretchable cellophane, including its use in packaging, textiles, and other industries. The improved stretchability allows for new possibilities in product design and functionality, expanding the potential uses of cellophane-based materials.

- Measurement and characterization of cellophane stretchability: Development of methods and techniques for accurately measuring and characterizing the stretchability of cellophane. This includes the creation of standardized testing procedures and the use of specialized equipment to quantify the material's elastic properties and performance under various conditions.

- Biodegradable and eco-friendly stretchable cellophane: Research and development of biodegradable and environmentally friendly stretchable cellophane alternatives. These materials aim to combine the desired stretchability with improved sustainability and reduced environmental impact, addressing growing concerns about plastic pollution and waste management.

02 Manufacturing processes for stretchable cellophane

Innovative manufacturing techniques and processes designed to produce cellophane with increased stretchability. These methods may involve modifications to traditional cellophane production processes, such as adjustments in the casting or treatment stages, to enhance the material's elastic properties.Expand Specific Solutions03 Applications of stretchable cellophane

Exploration of various applications for stretchable cellophane, including its use in packaging, textiles, and other industries. The improved stretchability of the material opens up new possibilities for its utilization in products requiring flexibility and adaptability.Expand Specific Solutions04 Measurement and characterization of cellophane stretchability

Development of methods and techniques for accurately measuring and characterizing the stretchability of cellophane. This includes the creation of standardized testing procedures and the use of specialized equipment to quantify the material's elastic properties and performance under various conditions.Expand Specific Solutions05 Biodegradable and eco-friendly stretchable cellophane

Research and development of biodegradable and environmentally friendly stretchable cellophane alternatives. These materials aim to combine the desired stretchability with improved sustainability and reduced environmental impact, addressing growing concerns about plastic pollution and waste management.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The market for stretchable cellophane innovation is in its early growth stage, with increasing demand driven by applications in flexible electronics and packaging. The technology's maturity varies across different players, with established companies like Nitto Denko and Agfa-Gevaert leading in advanced materials development. Emerging players such as Wilson Wolf Manufacturing and Nanocomp Technologies are focusing on niche applications, while research institutions like A*STAR and Harvard University contribute to fundamental advancements. The market size is expanding, fueled by growing interest in sustainable and adaptable materials across industries, including consumer electronics, healthcare, and automotive sectors.

Nitto Denko Corp.

Technical Solution: Nitto Denko Corp. has developed innovative stretchable cellophane technologies using their expertise in adhesive and film materials. Their approach involves creating a nanocomposite structure by incorporating elastic polymers into a cellophane matrix. This results in a material that can stretch up to 200% of its original length while maintaining transparency and barrier properties [1]. The company has also implemented a proprietary coating process that enhances the material's resistance to environmental factors such as humidity and temperature fluctuations [3]. Additionally, Nitto Denko has developed a unique lamination technique that allows for the integration of conductive elements within the stretchable cellophane, enabling applications in flexible electronics and smart packaging [5].

Strengths: Advanced material science capabilities, extensive experience in film and adhesive technologies, and a strong focus on R&D. Weaknesses: Potential high production costs and scalability challenges for mass production.

President & Fellows of Harvard College

Technical Solution: Harvard researchers have pioneered a novel approach to stretchable cellophane innovation by developing a biomimetic material inspired by spider silk. Their technique involves creating a nanofiber network within the cellophane structure, allowing for exceptional elasticity and strength. The material can stretch up to 300% of its original length while maintaining transparency [2]. The team has also incorporated self-healing properties into the stretchable cellophane by introducing dynamic cross-linking agents, enabling the material to recover from small tears and punctures [4]. Furthermore, Harvard's research has led to the development of a scalable manufacturing process that utilizes green chemistry principles, reducing environmental impact [6].

Strengths: Cutting-edge research capabilities, interdisciplinary approach combining materials science and biology, and focus on sustainable manufacturing. Weaknesses: Potential challenges in translating academic research into commercial products.

Breakthrough Patents in Polymer Science for Cellophane

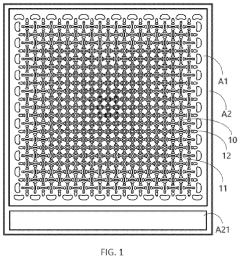

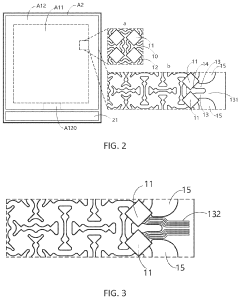

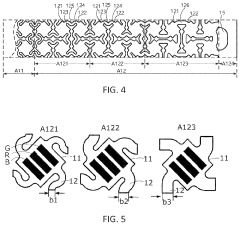

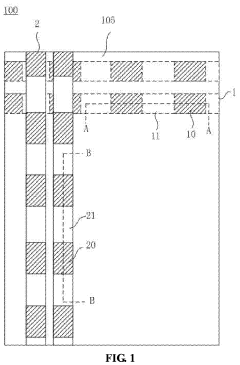

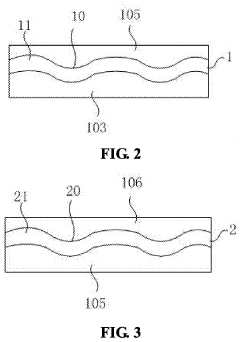

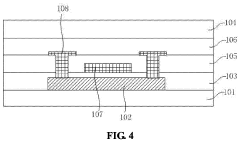

Stretchable display panel and display device

PatentActiveUS12016220B2

Innovation

- A stretchable display panel design featuring island structures with pixel units, bridge structures connecting adjacent islands, and increasing bridge widths towards the wiring area, along with strategically placed openings to enhance tensile strength and prevent wire breakage, includes a flexible substrate and inorganic and organic layers for improved mechanical stability.

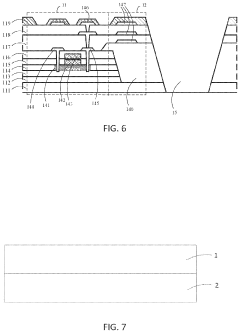

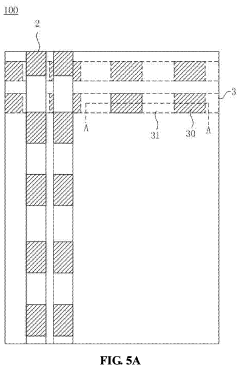

Array substrate, method of manufacturing same, and display panel

PatentActiveUS20210126074A1

Innovation

- The array substrate design includes multiple metal traces with alternating recesses and protrusions, which are electrically insulated from each other, and a specific manufacturing method that forms these traces with varying thicknesses in insulating layers to increase wiring space and prevent breakage during bending and stretching.

Environmental Impact of Stretchable Cellophane Production

The production of stretchable cellophane presents several environmental challenges that require careful consideration and mitigation strategies. The manufacturing process involves the use of various chemicals and energy-intensive procedures, which can have significant environmental impacts if not properly managed.

One of the primary concerns is the use of raw materials. Traditional cellophane production relies heavily on wood pulp, which contributes to deforestation if not sourced sustainably. The development of stretchable cellophane may introduce additional synthetic components, potentially increasing the reliance on petroleum-based materials. This shift could lead to increased carbon emissions and resource depletion associated with the extraction and processing of these materials.

Water consumption and pollution are also critical issues in cellophane production. The manufacturing process requires substantial amounts of water for washing and processing, potentially straining local water resources. Moreover, the chemical treatments used to enhance the stretchability of cellophane can result in wastewater containing harmful substances. Without proper treatment, these effluents can contaminate water bodies and harm aquatic ecosystems.

Energy consumption is another significant factor contributing to the environmental footprint of stretchable cellophane production. The process typically involves high-temperature treatments and mechanical processing, which demand considerable energy inputs. The source of this energy plays a crucial role in determining the overall environmental impact, with renewable energy sources offering a more sustainable alternative to fossil fuel-based power.

Air emissions from the production facilities are also a concern. Volatile organic compounds (VOCs) and other air pollutants may be released during the manufacturing process, particularly if solvents or chemical treatments are used to achieve the desired stretchable properties. These emissions can contribute to local air quality issues and potentially impact human health in surrounding communities.

Waste generation is an additional environmental challenge. The production of stretchable cellophane may result in off-cuts, defective products, and other waste materials that require proper disposal or recycling. The complexity of the material composition in stretchable cellophane could make recycling more difficult compared to traditional cellophane, potentially leading to increased landfill waste.

To address these environmental concerns, manufacturers are exploring various sustainable practices. These include developing bio-based alternatives to petroleum-derived materials, implementing closed-loop water systems to reduce water consumption and pollution, and investing in energy-efficient technologies and renewable energy sources. Additionally, efforts are being made to improve the recyclability of stretchable cellophane products and to minimize waste throughout the production process.

One of the primary concerns is the use of raw materials. Traditional cellophane production relies heavily on wood pulp, which contributes to deforestation if not sourced sustainably. The development of stretchable cellophane may introduce additional synthetic components, potentially increasing the reliance on petroleum-based materials. This shift could lead to increased carbon emissions and resource depletion associated with the extraction and processing of these materials.

Water consumption and pollution are also critical issues in cellophane production. The manufacturing process requires substantial amounts of water for washing and processing, potentially straining local water resources. Moreover, the chemical treatments used to enhance the stretchability of cellophane can result in wastewater containing harmful substances. Without proper treatment, these effluents can contaminate water bodies and harm aquatic ecosystems.

Energy consumption is another significant factor contributing to the environmental footprint of stretchable cellophane production. The process typically involves high-temperature treatments and mechanical processing, which demand considerable energy inputs. The source of this energy plays a crucial role in determining the overall environmental impact, with renewable energy sources offering a more sustainable alternative to fossil fuel-based power.

Air emissions from the production facilities are also a concern. Volatile organic compounds (VOCs) and other air pollutants may be released during the manufacturing process, particularly if solvents or chemical treatments are used to achieve the desired stretchable properties. These emissions can contribute to local air quality issues and potentially impact human health in surrounding communities.

Waste generation is an additional environmental challenge. The production of stretchable cellophane may result in off-cuts, defective products, and other waste materials that require proper disposal or recycling. The complexity of the material composition in stretchable cellophane could make recycling more difficult compared to traditional cellophane, potentially leading to increased landfill waste.

To address these environmental concerns, manufacturers are exploring various sustainable practices. These include developing bio-based alternatives to petroleum-derived materials, implementing closed-loop water systems to reduce water consumption and pollution, and investing in energy-efficient technologies and renewable energy sources. Additionally, efforts are being made to improve the recyclability of stretchable cellophane products and to minimize waste throughout the production process.

Regulatory Framework for Novel Packaging Materials

The regulatory framework for novel packaging materials, particularly in the context of stretchable cellophane innovation, is a complex and evolving landscape. As new materials and technologies emerge, regulatory bodies must adapt to ensure consumer safety, environmental protection, and fair market practices.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating food contact materials, including innovative packaging solutions like stretchable cellophane. The FDA's Food Contact Notification (FCN) program is the primary mechanism for reviewing and approving new food contact substances. Manufacturers of novel packaging materials must demonstrate the safety and efficacy of their products through rigorous testing and documentation.

The European Union has implemented a comprehensive regulatory framework for food contact materials through Regulation (EC) No 1935/2004. This regulation establishes general principles of safety and inertness for all food contact materials. For specific materials like stretchable cellophane, additional regulations may apply, such as Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Environmental considerations are increasingly shaping the regulatory landscape for packaging materials. Many jurisdictions are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. The EU's Circular Economy Action Plan, for instance, aims to make all packaging reusable or recyclable by 2030, potentially impacting the development and adoption of stretchable cellophane technologies.

Standardization bodies, such as the International Organization for Standardization (ISO) and ASTM International, play a vital role in establishing testing methods and performance criteria for novel packaging materials. These standards often inform regulatory decisions and help ensure consistency across different markets.

As the field of stretchable cellophane innovation advances, regulators face the challenge of balancing innovation with safety and sustainability. Adaptive regulatory approaches, such as regulatory sandboxes or pilot programs, may be employed to allow for controlled testing and evaluation of new packaging technologies before full-scale implementation.

Manufacturers and researchers in the stretchable cellophane space must stay abreast of these regulatory developments and engage proactively with regulatory bodies. Early consultation and collaboration can help streamline the approval process and ensure that innovative packaging solutions meet all necessary safety and environmental standards.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating food contact materials, including innovative packaging solutions like stretchable cellophane. The FDA's Food Contact Notification (FCN) program is the primary mechanism for reviewing and approving new food contact substances. Manufacturers of novel packaging materials must demonstrate the safety and efficacy of their products through rigorous testing and documentation.

The European Union has implemented a comprehensive regulatory framework for food contact materials through Regulation (EC) No 1935/2004. This regulation establishes general principles of safety and inertness for all food contact materials. For specific materials like stretchable cellophane, additional regulations may apply, such as Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Environmental considerations are increasingly shaping the regulatory landscape for packaging materials. Many jurisdictions are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. The EU's Circular Economy Action Plan, for instance, aims to make all packaging reusable or recyclable by 2030, potentially impacting the development and adoption of stretchable cellophane technologies.

Standardization bodies, such as the International Organization for Standardization (ISO) and ASTM International, play a vital role in establishing testing methods and performance criteria for novel packaging materials. These standards often inform regulatory decisions and help ensure consistency across different markets.

As the field of stretchable cellophane innovation advances, regulators face the challenge of balancing innovation with safety and sustainability. Adaptive regulatory approaches, such as regulatory sandboxes or pilot programs, may be employed to allow for controlled testing and evaluation of new packaging technologies before full-scale implementation.

Manufacturers and researchers in the stretchable cellophane space must stay abreast of these regulatory developments and engage proactively with regulatory bodies. Early consultation and collaboration can help streamline the approval process and ensure that innovative packaging solutions meet all necessary safety and environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!