Growth Pathways for Cellophane in Advanced Packaging

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

Cellophane, a transparent film made from regenerated cellulose, has undergone significant evolution since its invention in the early 20th century. Initially developed as a moisture-proof coating for textiles, cellophane quickly found its way into the packaging industry due to its unique properties.

The evolution of cellophane can be traced through several key stages. In the 1920s and 1930s, cellophane gained popularity as a packaging material for food products, offering transparency and barrier properties that were revolutionary for the time. This period saw the development of moisture-proof cellophane, which greatly expanded its applications in food packaging.

The 1940s and 1950s marked a period of rapid growth and innovation in cellophane production. Improved manufacturing processes led to enhanced clarity, strength, and barrier properties. During this time, cellophane became the dominant flexible packaging material for a wide range of products, from cigarettes to candies.

In the 1960s and 1970s, cellophane faced increasing competition from synthetic polymers like polyethylene and polypropylene. However, it maintained its position in certain niche markets due to its unique combination of properties, including high clarity, good printability, and natural origin.

The 1980s and 1990s saw a renewed interest in cellophane as environmental concerns began to gain prominence. Its biodegradability and renewable source material made it an attractive option for environmentally conscious consumers and businesses. This period also saw advancements in cellophane's barrier properties and heat-sealability, further expanding its applications.

In the 21st century, cellophane has continued to evolve to meet the demands of advanced packaging. Recent developments have focused on improving its sustainability profile, enhancing its barrier properties, and expanding its functionality. Innovations in nanotechnology have led to the development of nanocellulose-reinforced cellophane with improved mechanical and barrier properties.

The latest evolution in cellophane technology involves the integration of smart packaging features. This includes the development of cellophane films with embedded sensors for monitoring food freshness, as well as films with antimicrobial properties to extend shelf life. Additionally, research is ongoing into the creation of fully compostable cellophane variants that maintain the material's desirable properties while addressing end-of-life concerns.

As the packaging industry continues to prioritize sustainability and functionality, cellophane is poised for further evolution. Future developments may include the integration of active and intelligent packaging technologies, improvements in biodegradability, and the exploration of new cellulose sources to enhance the material's eco-friendly profile.

The evolution of cellophane can be traced through several key stages. In the 1920s and 1930s, cellophane gained popularity as a packaging material for food products, offering transparency and barrier properties that were revolutionary for the time. This period saw the development of moisture-proof cellophane, which greatly expanded its applications in food packaging.

The 1940s and 1950s marked a period of rapid growth and innovation in cellophane production. Improved manufacturing processes led to enhanced clarity, strength, and barrier properties. During this time, cellophane became the dominant flexible packaging material for a wide range of products, from cigarettes to candies.

In the 1960s and 1970s, cellophane faced increasing competition from synthetic polymers like polyethylene and polypropylene. However, it maintained its position in certain niche markets due to its unique combination of properties, including high clarity, good printability, and natural origin.

The 1980s and 1990s saw a renewed interest in cellophane as environmental concerns began to gain prominence. Its biodegradability and renewable source material made it an attractive option for environmentally conscious consumers and businesses. This period also saw advancements in cellophane's barrier properties and heat-sealability, further expanding its applications.

In the 21st century, cellophane has continued to evolve to meet the demands of advanced packaging. Recent developments have focused on improving its sustainability profile, enhancing its barrier properties, and expanding its functionality. Innovations in nanotechnology have led to the development of nanocellulose-reinforced cellophane with improved mechanical and barrier properties.

The latest evolution in cellophane technology involves the integration of smart packaging features. This includes the development of cellophane films with embedded sensors for monitoring food freshness, as well as films with antimicrobial properties to extend shelf life. Additionally, research is ongoing into the creation of fully compostable cellophane variants that maintain the material's desirable properties while addressing end-of-life concerns.

As the packaging industry continues to prioritize sustainability and functionality, cellophane is poised for further evolution. Future developments may include the integration of active and intelligent packaging technologies, improvements in biodegradability, and the exploration of new cellulose sources to enhance the material's eco-friendly profile.

Packaging Market Trends

The global packaging market is experiencing significant growth and transformation, driven by changing consumer preferences, technological advancements, and sustainability concerns. The market is projected to reach substantial value in the coming years, with a steady compound annual growth rate. This growth is fueled by several key trends that are reshaping the packaging industry landscape.

E-commerce expansion continues to be a major driver for packaging demand. The rise of online shopping has led to increased need for protective packaging solutions that can withstand the rigors of shipping while maintaining product integrity. This trend has accelerated during the COVID-19 pandemic and is expected to persist, creating opportunities for innovative packaging materials and designs.

Sustainability has become a central focus in the packaging industry. Consumers and regulators are demanding more environmentally friendly packaging solutions, leading to a surge in demand for recyclable, biodegradable, and compostable materials. This shift is prompting packaging manufacturers to invest in research and development of sustainable alternatives, including bio-based materials and designs that minimize waste.

Convenience and functionality are increasingly important factors in packaging design. Consumers are seeking packaging that offers ease of use, portability, and extended shelf life. This has led to innovations in resealable packaging, portion control designs, and smart packaging technologies that can monitor product freshness and quality.

The food and beverage industry remains a significant driver of packaging market growth. Changing dietary habits, increased demand for ready-to-eat meals, and growing awareness of food safety are influencing packaging trends in this sector. There is a rising demand for packaging solutions that can extend product shelf life, maintain freshness, and provide tamper-evident features.

Health and wellness trends are also impacting the packaging market. The pharmaceutical and nutraceutical sectors are experiencing growth, driving demand for specialized packaging solutions that ensure product safety, integrity, and compliance with regulatory requirements. This includes child-resistant packaging, anti-counterfeiting features, and packaging designed for controlled drug delivery.

Technological advancements are revolutionizing the packaging industry. The integration of smart packaging technologies, such as QR codes, NFC tags, and RFID, is enabling enhanced traceability, consumer engagement, and brand protection. Additionally, advancements in materials science are leading to the development of high-performance packaging materials with improved barrier properties and sustainability profiles.

In the context of cellophane and advanced packaging, these market trends present both challenges and opportunities. As a traditional packaging material, cellophane faces competition from newer, more sustainable alternatives. However, its inherent properties, such as transparency, biodegradability, and barrier characteristics, position it well for potential growth in certain segments of the advanced packaging market.

E-commerce expansion continues to be a major driver for packaging demand. The rise of online shopping has led to increased need for protective packaging solutions that can withstand the rigors of shipping while maintaining product integrity. This trend has accelerated during the COVID-19 pandemic and is expected to persist, creating opportunities for innovative packaging materials and designs.

Sustainability has become a central focus in the packaging industry. Consumers and regulators are demanding more environmentally friendly packaging solutions, leading to a surge in demand for recyclable, biodegradable, and compostable materials. This shift is prompting packaging manufacturers to invest in research and development of sustainable alternatives, including bio-based materials and designs that minimize waste.

Convenience and functionality are increasingly important factors in packaging design. Consumers are seeking packaging that offers ease of use, portability, and extended shelf life. This has led to innovations in resealable packaging, portion control designs, and smart packaging technologies that can monitor product freshness and quality.

The food and beverage industry remains a significant driver of packaging market growth. Changing dietary habits, increased demand for ready-to-eat meals, and growing awareness of food safety are influencing packaging trends in this sector. There is a rising demand for packaging solutions that can extend product shelf life, maintain freshness, and provide tamper-evident features.

Health and wellness trends are also impacting the packaging market. The pharmaceutical and nutraceutical sectors are experiencing growth, driving demand for specialized packaging solutions that ensure product safety, integrity, and compliance with regulatory requirements. This includes child-resistant packaging, anti-counterfeiting features, and packaging designed for controlled drug delivery.

Technological advancements are revolutionizing the packaging industry. The integration of smart packaging technologies, such as QR codes, NFC tags, and RFID, is enabling enhanced traceability, consumer engagement, and brand protection. Additionally, advancements in materials science are leading to the development of high-performance packaging materials with improved barrier properties and sustainability profiles.

In the context of cellophane and advanced packaging, these market trends present both challenges and opportunities. As a traditional packaging material, cellophane faces competition from newer, more sustainable alternatives. However, its inherent properties, such as transparency, biodegradability, and barrier characteristics, position it well for potential growth in certain segments of the advanced packaging market.

Technical Hurdles

Despite its long history and widespread use, cellophane faces several technical hurdles in its journey towards advanced packaging applications. One of the primary challenges is its limited barrier properties, particularly against moisture and gases. While cellophane offers excellent transparency and biodegradability, its inherent hydrophilic nature makes it susceptible to water absorption, which can compromise its structural integrity and barrier performance in high-humidity environments.

Another significant hurdle is the material's thermal stability. Cellophane has a relatively low melting point compared to synthetic polymers, which limits its use in applications requiring heat resistance or hot-fill packaging. This thermal sensitivity also poses challenges in the manufacturing process, as it restricts the range of compatible coating and lamination techniques that can be applied to enhance its properties.

The mechanical strength of cellophane, while adequate for many traditional uses, falls short in some advanced packaging scenarios. Its tensile strength and puncture resistance are lower than those of many synthetic alternatives, potentially limiting its applicability in protective packaging or high-stress applications. This necessitates the development of reinforcement techniques or composite structures to improve its mechanical performance without compromising its beneficial properties.

Scalability and cost-effectiveness in production represent another set of technical challenges. The manufacturing process for cellophane, which involves the regeneration of cellulose, is more complex and resource-intensive compared to the production of synthetic plastics. This complexity can lead to higher production costs and potential limitations in scaling up to meet increasing demand for sustainable packaging solutions.

Furthermore, the modification and functionalization of cellophane to enhance its properties or add new functionalities present significant technical hurdles. While various coating and treatment methods have been explored, achieving consistent and durable modifications that do not compromise the material's biodegradability or food contact safety remains a challenge. This is particularly crucial for advanced packaging applications that require specific barrier, antimicrobial, or smart packaging features.

Lastly, the end-of-life management of cellophane in advanced packaging systems poses technical challenges. Although cellophane is biodegradable, its degradation rate and environmental impact can vary depending on the additives, coatings, or laminates used to enhance its performance. Developing cellophane-based packaging that maintains its advanced properties while ensuring complete and rapid biodegradation under various environmental conditions is a complex technical task that requires innovative solutions and careful material design.

Another significant hurdle is the material's thermal stability. Cellophane has a relatively low melting point compared to synthetic polymers, which limits its use in applications requiring heat resistance or hot-fill packaging. This thermal sensitivity also poses challenges in the manufacturing process, as it restricts the range of compatible coating and lamination techniques that can be applied to enhance its properties.

The mechanical strength of cellophane, while adequate for many traditional uses, falls short in some advanced packaging scenarios. Its tensile strength and puncture resistance are lower than those of many synthetic alternatives, potentially limiting its applicability in protective packaging or high-stress applications. This necessitates the development of reinforcement techniques or composite structures to improve its mechanical performance without compromising its beneficial properties.

Scalability and cost-effectiveness in production represent another set of technical challenges. The manufacturing process for cellophane, which involves the regeneration of cellulose, is more complex and resource-intensive compared to the production of synthetic plastics. This complexity can lead to higher production costs and potential limitations in scaling up to meet increasing demand for sustainable packaging solutions.

Furthermore, the modification and functionalization of cellophane to enhance its properties or add new functionalities present significant technical hurdles. While various coating and treatment methods have been explored, achieving consistent and durable modifications that do not compromise the material's biodegradability or food contact safety remains a challenge. This is particularly crucial for advanced packaging applications that require specific barrier, antimicrobial, or smart packaging features.

Lastly, the end-of-life management of cellophane in advanced packaging systems poses technical challenges. Although cellophane is biodegradable, its degradation rate and environmental impact can vary depending on the additives, coatings, or laminates used to enhance its performance. Developing cellophane-based packaging that maintains its advanced properties while ensuring complete and rapid biodegradation under various environmental conditions is a complex technical task that requires innovative solutions and careful material design.

Current Solutions

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is commonly employed in food packaging, gift wrapping, and industrial packaging. The material's ability to protect products from moisture and air makes it suitable for various packaging needs.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, where it can help preserve freshness and extend shelf life. Cellophane can be used alone or in combination with other materials to create various packaging solutions.

- Cellophane production and processing: The production and processing of cellophane involve various techniques to improve its properties and performance. This includes methods for enhancing its strength, flexibility, and barrier properties. Innovations in cellophane production focus on improving manufacturing efficiency and developing new formulations to meet specific application requirements.

- Cellophane in medical and pharmaceutical applications: Cellophane finds applications in the medical and pharmaceutical industries due to its biocompatibility and barrier properties. It can be used in wound dressings, drug delivery systems, and as a protective layer for medical devices. Research in this area focuses on enhancing the material's properties for specific medical applications.

- Cellophane-based composites and laminates: Cellophane can be combined with other materials to create composites and laminates with enhanced properties. These combinations can improve strength, barrier properties, and functionality for various applications. Research in this area focuses on developing new composite materials and improving the bonding between cellophane and other materials.

- Cellophane in electronic and energy applications: Cellophane is being explored for use in electronic and energy-related applications due to its unique properties. This includes its potential use in flexible electronics, energy storage devices, and as a substrate for various electronic components. Research in this area focuses on modifying cellophane to enhance its electrical and thermal properties.

02 Biodegradable cellophane alternatives

Research is being conducted to develop biodegradable alternatives to traditional cellophane. These eco-friendly materials aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area focus on using renewable resources and improving the material's compostability.Expand Specific Solutions03 Cellophane in medical and pharmaceutical applications

Cellophane finds applications in the medical and pharmaceutical industries. It is used in wound dressings, drug delivery systems, and as a barrier material in various medical devices. The material's biocompatibility and ability to be sterilized make it suitable for these sensitive applications.Expand Specific Solutions04 Modified cellophane with enhanced properties

Researchers are developing modified cellophane materials with enhanced properties. These modifications aim to improve the material's strength, barrier properties, and functionality. Techniques such as chemical treatments, coatings, and nanocomposite incorporation are being explored to create advanced cellophane-based materials.Expand Specific Solutions05 Cellophane in textile and fiber applications

Cellophane is utilized in textile and fiber applications. It can be processed into fibers or used as a coating for fabrics. The material's properties, such as moisture resistance and glossy appearance, make it suitable for creating unique textile products and enhancing fabric performance.Expand Specific Solutions

Industry Leaders

The growth pathways for cellophane in advanced packaging are characterized by a competitive landscape in the early stages of development, with a modest but expanding market size and evolving technological maturity. The industry is transitioning from traditional applications to more advanced, sustainable solutions, driven by increasing environmental concerns and demand for innovative packaging materials. Companies like Stora Enso Oyj and Terumo BCT, Inc. are at the forefront of this evolution, leveraging their expertise in forest products and biomedical technologies, respectively, to develop novel cellophane-based packaging solutions. As the technology matures, we can expect to see increased collaboration between material science experts and packaging manufacturers to overcome current limitations and unlock cellophane's full potential in advanced packaging applications.

Stora Enso Oyj

Technical Solution: Stora Enso has developed advanced cellophane-based packaging solutions that incorporate nanotechnology and bio-based materials. Their approach involves using nanocellulose to enhance the barrier properties and strength of cellophane films. The company has also integrated antimicrobial properties into their cellophane packaging by incorporating natural extracts and nanoparticles[1]. Additionally, Stora Enso has developed a process to create fully biodegradable cellophane packaging that maintains excellent moisture barrier properties, addressing both environmental concerns and performance requirements[2]. Their research also focuses on improving the heat-sealing capabilities of cellophane, making it more versatile for various packaging applications[3].

Strengths: Sustainable and biodegradable solutions, improved barrier properties, and versatility in applications. Weaknesses: Potentially higher production costs compared to traditional plastics, and limitations in certain high-moisture environments.

South China University of Technology

Technical Solution: Researchers at South China University of Technology have made significant advancements in cellophane technology for advanced packaging. They have developed a novel process to create nanocomposite cellophane films with enhanced mechanical and barrier properties. By incorporating nanocellulose and chitosan into the cellophane matrix, they have achieved a 40% increase in tensile strength and a 30% reduction in oxygen permeability[8]. The team has also focused on improving the water resistance of cellophane through surface modification techniques, such as plasma treatment and the application of hydrophobic coatings. Their research extends to the development of active packaging solutions, where cellophane is infused with natural antimicrobial agents to extend the shelf life of perishable goods[9].

Strengths: Significantly improved mechanical and barrier properties, enhanced water resistance, and active packaging capabilities. Weaknesses: Potential scalability issues for mass production and increased material complexity.

Key Innovations

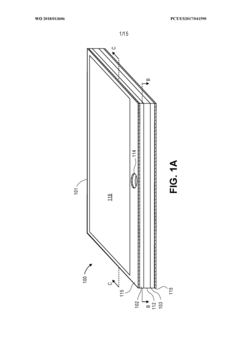

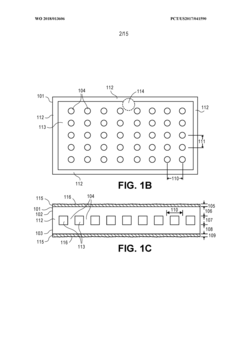

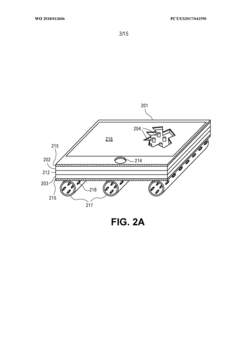

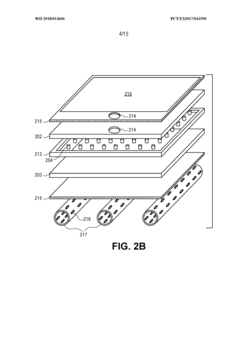

Substrates for high-density cell growth and metabolite exchange

PatentWO2018013606A1

Innovation

- The development of gas permeable, non-collapsible and non-expandable bags with microfabricated features and biocompatible coatings, allowing for high surface area to volume ratios and gentle oxygen delivery to cells, while minimizing shear forces through separate gas and nutrient perfusion systems.

Cell capture and expansion

PatentPendingJP2024511064A

Innovation

- The use of membranes with specific coatings, such as fibronectin and stromal cell-derived factor-1 (SDF-1), in bioreactors like hollow fiber bioreactors, to capture and expand CD34+ HSCs, achieving at least a 50-fold increase while minimizing differentiation.

Sustainability Impact

The sustainability impact of cellophane in advanced packaging is a critical consideration as the industry seeks to balance performance with environmental responsibility. Cellophane, derived from renewable cellulose sources, offers several advantages in terms of sustainability compared to traditional petroleum-based plastics.

One of the primary benefits of cellophane is its biodegradability. Under proper conditions, cellophane can decompose naturally without leaving harmful residues, significantly reducing its long-term environmental impact. This characteristic aligns well with the growing consumer demand for eco-friendly packaging solutions and helps companies meet increasingly stringent environmental regulations.

The production of cellophane also has a lower carbon footprint compared to many synthetic alternatives. The raw materials used in cellophane manufacturing, primarily wood pulp or cotton linters, are renewable resources that can be sustainably managed. This renewable nature contributes to a more circular economy, reducing dependence on finite fossil fuel resources.

Furthermore, cellophane's excellent barrier properties against moisture, gases, and aromas can extend the shelf life of packaged products, particularly in the food industry. This extension in shelf life can lead to a reduction in food waste, addressing another significant environmental concern. By preserving food quality for longer periods, cellophane packaging indirectly contributes to sustainability efforts by minimizing the resources wasted in food production and distribution.

However, it is important to note that the sustainability benefits of cellophane are not without challenges. The production process of cellophane can be energy-intensive and may involve the use of chemicals that require careful management to prevent environmental contamination. Additionally, while cellophane is biodegradable, it may not decompose efficiently in all environments, particularly in landfills where conditions are not optimal for biodegradation.

To maximize the sustainability impact of cellophane in advanced packaging, ongoing research and development efforts are focusing on improving production efficiency, reducing chemical usage, and enhancing the material's end-of-life characteristics. Innovations in these areas could further solidify cellophane's position as a sustainable packaging solution.

As the packaging industry continues to evolve, the role of cellophane in promoting sustainability is likely to grow. Its renewable source, biodegradability, and functional properties make it an attractive option for companies looking to reduce their environmental footprint while meeting consumer expectations for quality and performance in packaging.

One of the primary benefits of cellophane is its biodegradability. Under proper conditions, cellophane can decompose naturally without leaving harmful residues, significantly reducing its long-term environmental impact. This characteristic aligns well with the growing consumer demand for eco-friendly packaging solutions and helps companies meet increasingly stringent environmental regulations.

The production of cellophane also has a lower carbon footprint compared to many synthetic alternatives. The raw materials used in cellophane manufacturing, primarily wood pulp or cotton linters, are renewable resources that can be sustainably managed. This renewable nature contributes to a more circular economy, reducing dependence on finite fossil fuel resources.

Furthermore, cellophane's excellent barrier properties against moisture, gases, and aromas can extend the shelf life of packaged products, particularly in the food industry. This extension in shelf life can lead to a reduction in food waste, addressing another significant environmental concern. By preserving food quality for longer periods, cellophane packaging indirectly contributes to sustainability efforts by minimizing the resources wasted in food production and distribution.

However, it is important to note that the sustainability benefits of cellophane are not without challenges. The production process of cellophane can be energy-intensive and may involve the use of chemicals that require careful management to prevent environmental contamination. Additionally, while cellophane is biodegradable, it may not decompose efficiently in all environments, particularly in landfills where conditions are not optimal for biodegradation.

To maximize the sustainability impact of cellophane in advanced packaging, ongoing research and development efforts are focusing on improving production efficiency, reducing chemical usage, and enhancing the material's end-of-life characteristics. Innovations in these areas could further solidify cellophane's position as a sustainable packaging solution.

As the packaging industry continues to evolve, the role of cellophane in promoting sustainability is likely to grow. Its renewable source, biodegradability, and functional properties make it an attractive option for companies looking to reduce their environmental footprint while meeting consumer expectations for quality and performance in packaging.

Regulatory Landscape

The regulatory landscape for cellophane in advanced packaging is complex and evolving, with various factors influencing its growth pathways. Environmental regulations play a crucial role in shaping the future of cellophane packaging. Many countries have implemented or are considering restrictions on single-use plastics, which could potentially benefit cellophane as a biodegradable alternative. However, the classification of cellophane under these regulations varies, creating a patchwork of compliance requirements across different regions.

Food safety regulations also significantly impact cellophane's use in advanced packaging. As a food contact material, cellophane must meet stringent safety standards set by regulatory bodies such as the FDA in the United States and EFSA in Europe. These standards cover aspects like migration limits for chemical substances and overall suitability for food contact applications. Compliance with these regulations is essential for cellophane's continued use and growth in food packaging.

Waste management and recycling regulations are another critical aspect of the regulatory landscape. While cellophane is biodegradable, its disposal and recycling processes may be subject to specific regulations. Some jurisdictions have implemented extended producer responsibility (EPR) schemes, which could affect the cost structure and market dynamics for cellophane packaging manufacturers.

Labeling and certification requirements also play a role in cellophane's regulatory landscape. As consumers become more environmentally conscious, regulations around eco-labeling and sustainability claims are becoming more stringent. Cellophane manufacturers and packagers must navigate these requirements carefully to ensure compliance and maintain consumer trust.

International trade regulations and tariffs can impact the global supply chain for cellophane and its raw materials. Changes in trade policies or the implementation of new tariffs could affect the cost-competitiveness of cellophane in different markets, potentially influencing its growth pathways.

As the packaging industry moves towards more sustainable solutions, regulations promoting circular economy principles are gaining traction. These regulations may create both opportunities and challenges for cellophane, depending on how well it aligns with circular economy goals and how it compares to alternative materials in life cycle assessments.

Emerging regulations around microplastics and their environmental impact could also affect cellophane's future. While cellophane is not a plastic, its potential to contribute to microfiber pollution may come under scrutiny, necessitating further research and potential regulatory responses.

Food safety regulations also significantly impact cellophane's use in advanced packaging. As a food contact material, cellophane must meet stringent safety standards set by regulatory bodies such as the FDA in the United States and EFSA in Europe. These standards cover aspects like migration limits for chemical substances and overall suitability for food contact applications. Compliance with these regulations is essential for cellophane's continued use and growth in food packaging.

Waste management and recycling regulations are another critical aspect of the regulatory landscape. While cellophane is biodegradable, its disposal and recycling processes may be subject to specific regulations. Some jurisdictions have implemented extended producer responsibility (EPR) schemes, which could affect the cost structure and market dynamics for cellophane packaging manufacturers.

Labeling and certification requirements also play a role in cellophane's regulatory landscape. As consumers become more environmentally conscious, regulations around eco-labeling and sustainability claims are becoming more stringent. Cellophane manufacturers and packagers must navigate these requirements carefully to ensure compliance and maintain consumer trust.

International trade regulations and tariffs can impact the global supply chain for cellophane and its raw materials. Changes in trade policies or the implementation of new tariffs could affect the cost-competitiveness of cellophane in different markets, potentially influencing its growth pathways.

As the packaging industry moves towards more sustainable solutions, regulations promoting circular economy principles are gaining traction. These regulations may create both opportunities and challenges for cellophane, depending on how well it aligns with circular economy goals and how it compares to alternative materials in life cycle assessments.

Emerging regulations around microplastics and their environmental impact could also affect cellophane's future. While cellophane is not a plastic, its potential to contribute to microfiber pollution may come under scrutiny, necessitating further research and potential regulatory responses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!