How to Develop Robust Anti-Fogging Cellophane?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Fogging Cellophane Background and Objectives

Anti-fogging cellophane has emerged as a critical technology in various industries, particularly in food packaging, agriculture, and consumer goods. The development of this innovative material traces its roots back to the mid-20th century when researchers began exploring ways to prevent condensation on transparent surfaces. Over the decades, the technology has evolved significantly, driven by the increasing demand for improved food preservation and enhanced product visibility.

The primary objective of developing robust anti-fogging cellophane is to create a material that maintains clarity and transparency under varying temperature and humidity conditions. This goal addresses the persistent challenge of fog formation on packaging materials, which can obscure product visibility and potentially compromise food quality. By preventing fog formation, anti-fogging cellophane aims to extend shelf life, reduce food waste, and enhance the overall consumer experience.

Recent technological advancements have focused on improving the durability and effectiveness of anti-fogging properties. This includes the development of more stable hydrophilic coatings, the integration of nanoparticles, and the exploration of novel surface modification techniques. These innovations seek to create longer-lasting anti-fog effects and broaden the range of applications for anti-fogging cellophane.

The evolution of anti-fogging cellophane technology is closely tied to broader trends in sustainable packaging and smart materials. As environmental concerns grow, there is an increasing emphasis on developing eco-friendly anti-fogging solutions that minimize the use of synthetic chemicals and improve recyclability. Additionally, the integration of anti-fogging properties with other functional characteristics, such as antimicrobial properties or oxygen barrier capabilities, represents a significant trend in the field.

Looking ahead, the development of robust anti-fogging cellophane faces several key challenges. These include enhancing the longevity of anti-fog effects, improving compatibility with a wider range of products and environmental conditions, and addressing cost-effectiveness for large-scale production. Overcoming these hurdles will be crucial in realizing the full potential of anti-fogging cellophane across various industries.

As research in this field progresses, the ultimate aim is to create a versatile, sustainable, and highly effective anti-fogging cellophane that can revolutionize packaging solutions. This technology has the potential to significantly impact food preservation, reduce waste, and improve product presentation across multiple sectors. The ongoing efforts in this area reflect the broader technological trend towards developing smart, responsive materials that can adapt to changing environmental conditions and meet evolving consumer needs.

The primary objective of developing robust anti-fogging cellophane is to create a material that maintains clarity and transparency under varying temperature and humidity conditions. This goal addresses the persistent challenge of fog formation on packaging materials, which can obscure product visibility and potentially compromise food quality. By preventing fog formation, anti-fogging cellophane aims to extend shelf life, reduce food waste, and enhance the overall consumer experience.

Recent technological advancements have focused on improving the durability and effectiveness of anti-fogging properties. This includes the development of more stable hydrophilic coatings, the integration of nanoparticles, and the exploration of novel surface modification techniques. These innovations seek to create longer-lasting anti-fog effects and broaden the range of applications for anti-fogging cellophane.

The evolution of anti-fogging cellophane technology is closely tied to broader trends in sustainable packaging and smart materials. As environmental concerns grow, there is an increasing emphasis on developing eco-friendly anti-fogging solutions that minimize the use of synthetic chemicals and improve recyclability. Additionally, the integration of anti-fogging properties with other functional characteristics, such as antimicrobial properties or oxygen barrier capabilities, represents a significant trend in the field.

Looking ahead, the development of robust anti-fogging cellophane faces several key challenges. These include enhancing the longevity of anti-fog effects, improving compatibility with a wider range of products and environmental conditions, and addressing cost-effectiveness for large-scale production. Overcoming these hurdles will be crucial in realizing the full potential of anti-fogging cellophane across various industries.

As research in this field progresses, the ultimate aim is to create a versatile, sustainable, and highly effective anti-fogging cellophane that can revolutionize packaging solutions. This technology has the potential to significantly impact food preservation, reduce waste, and improve product presentation across multiple sectors. The ongoing efforts in this area reflect the broader technological trend towards developing smart, responsive materials that can adapt to changing environmental conditions and meet evolving consumer needs.

Market Analysis for Anti-Fogging Packaging Solutions

The global market for anti-fogging packaging solutions has experienced significant growth in recent years, driven by increasing demand for improved food preservation and presentation. This trend is particularly evident in the fresh produce, ready-to-eat meals, and bakery sectors, where product visibility and extended shelf life are crucial factors for consumer appeal and reducing food waste.

The anti-fogging cellophane market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed the overall packaging industry average. This growth is fueled by the rising consumer preference for convenience foods, the expansion of organized retail, and the growing awareness of food safety and hygiene.

Geographically, North America and Europe currently dominate the anti-fogging packaging market, owing to their well-established food processing industries and stringent regulations on food packaging. However, the Asia-Pacific region is emerging as a lucrative market, with rapid urbanization, changing lifestyles, and increasing disposable incomes driving demand for packaged foods and, consequently, anti-fogging solutions.

The food and beverage industry remains the primary end-user of anti-fogging cellophane, accounting for the largest market share. Within this sector, fresh produce packaging represents a particularly promising segment, as consumers increasingly seek visually appealing and fresh-looking fruits and vegetables.

Market dynamics are also influenced by the growing emphasis on sustainable packaging solutions. This has led to increased research and development efforts focused on creating bio-based and biodegradable anti-fogging films, aligning with the broader trend towards environmentally friendly packaging materials.

Key market players are investing in technological advancements to improve the performance and durability of anti-fogging cellophane. These innovations aim to address challenges such as maintaining anti-fog properties over extended periods and under varying temperature and humidity conditions.

The COVID-19 pandemic has further accelerated market growth, as consumers have shown a preference for packaged and hygienically sealed food products. This shift in consumer behavior is expected to have a lasting impact on the anti-fogging packaging market, even as the immediate health crisis subsides.

In conclusion, the market analysis for anti-fogging packaging solutions, particularly anti-fogging cellophane, indicates a robust growth potential. The industry is poised for further expansion, driven by technological innovations, changing consumer preferences, and the increasing importance of food safety and presentation in the global retail landscape.

The anti-fogging cellophane market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed the overall packaging industry average. This growth is fueled by the rising consumer preference for convenience foods, the expansion of organized retail, and the growing awareness of food safety and hygiene.

Geographically, North America and Europe currently dominate the anti-fogging packaging market, owing to their well-established food processing industries and stringent regulations on food packaging. However, the Asia-Pacific region is emerging as a lucrative market, with rapid urbanization, changing lifestyles, and increasing disposable incomes driving demand for packaged foods and, consequently, anti-fogging solutions.

The food and beverage industry remains the primary end-user of anti-fogging cellophane, accounting for the largest market share. Within this sector, fresh produce packaging represents a particularly promising segment, as consumers increasingly seek visually appealing and fresh-looking fruits and vegetables.

Market dynamics are also influenced by the growing emphasis on sustainable packaging solutions. This has led to increased research and development efforts focused on creating bio-based and biodegradable anti-fogging films, aligning with the broader trend towards environmentally friendly packaging materials.

Key market players are investing in technological advancements to improve the performance and durability of anti-fogging cellophane. These innovations aim to address challenges such as maintaining anti-fog properties over extended periods and under varying temperature and humidity conditions.

The COVID-19 pandemic has further accelerated market growth, as consumers have shown a preference for packaged and hygienically sealed food products. This shift in consumer behavior is expected to have a lasting impact on the anti-fogging packaging market, even as the immediate health crisis subsides.

In conclusion, the market analysis for anti-fogging packaging solutions, particularly anti-fogging cellophane, indicates a robust growth potential. The industry is poised for further expansion, driven by technological innovations, changing consumer preferences, and the increasing importance of food safety and presentation in the global retail landscape.

Current Anti-Fogging Technologies and Challenges

Anti-fogging technologies for cellophane have made significant strides in recent years, yet challenges persist in developing robust and long-lasting solutions. Current approaches primarily focus on surface modification techniques and the application of anti-fogging coatings. One prevalent method involves the use of hydrophilic coatings that spread water droplets into a thin, transparent film. These coatings typically contain surfactants or polymers that reduce surface tension, allowing water to spread evenly rather than forming discrete droplets.

Another widely adopted technique is the incorporation of nanoparticles into the cellophane matrix or as a surface treatment. Nanoparticles, such as silica or titanium dioxide, can create a superhydrophilic surface that repels water droplets effectively. This approach has shown promising results in laboratory settings, but scaling up for industrial production remains a challenge.

Plasma treatment is an emerging technology in the anti-fogging arena. By exposing cellophane to low-temperature plasma, the surface properties can be altered to enhance hydrophilicity. This method offers the advantage of being environmentally friendly and potentially more cost-effective than chemical treatments. However, the durability of plasma-treated surfaces under real-world conditions is still a concern.

Despite these advancements, several challenges impede the development of truly robust anti-fogging cellophane. Durability is a primary concern, as many current anti-fogging treatments wear off over time or with repeated cleaning. Environmental factors such as temperature fluctuations, humidity, and exposure to various chemicals can degrade the effectiveness of anti-fogging coatings.

Another significant challenge is maintaining optical clarity while imparting anti-fogging properties. Some treatments can slightly alter the transparency or cause a haze, which is unacceptable for applications requiring high visual clarity, such as food packaging or optical lenses.

Cost-effectiveness and scalability present additional hurdles. Many advanced anti-fogging technologies that show promise in laboratory settings are difficult or expensive to implement on a large scale. This limits their practical application in mass-produced cellophane products.

Regulatory compliance is also a critical consideration, particularly for food-contact applications. Anti-fogging treatments must meet stringent safety standards and be free from harmful chemicals that could potentially migrate into food products.

As research continues, the focus is shifting towards developing multi-functional coatings that not only prevent fogging but also offer additional benefits such as antimicrobial properties or enhanced barrier characteristics. The integration of smart materials, such as thermochromic or electrochromic compounds, into anti-fogging systems is an area of growing interest, potentially leading to more adaptive and responsive cellophane products.

Another widely adopted technique is the incorporation of nanoparticles into the cellophane matrix or as a surface treatment. Nanoparticles, such as silica or titanium dioxide, can create a superhydrophilic surface that repels water droplets effectively. This approach has shown promising results in laboratory settings, but scaling up for industrial production remains a challenge.

Plasma treatment is an emerging technology in the anti-fogging arena. By exposing cellophane to low-temperature plasma, the surface properties can be altered to enhance hydrophilicity. This method offers the advantage of being environmentally friendly and potentially more cost-effective than chemical treatments. However, the durability of plasma-treated surfaces under real-world conditions is still a concern.

Despite these advancements, several challenges impede the development of truly robust anti-fogging cellophane. Durability is a primary concern, as many current anti-fogging treatments wear off over time or with repeated cleaning. Environmental factors such as temperature fluctuations, humidity, and exposure to various chemicals can degrade the effectiveness of anti-fogging coatings.

Another significant challenge is maintaining optical clarity while imparting anti-fogging properties. Some treatments can slightly alter the transparency or cause a haze, which is unacceptable for applications requiring high visual clarity, such as food packaging or optical lenses.

Cost-effectiveness and scalability present additional hurdles. Many advanced anti-fogging technologies that show promise in laboratory settings are difficult or expensive to implement on a large scale. This limits their practical application in mass-produced cellophane products.

Regulatory compliance is also a critical consideration, particularly for food-contact applications. Anti-fogging treatments must meet stringent safety standards and be free from harmful chemicals that could potentially migrate into food products.

As research continues, the focus is shifting towards developing multi-functional coatings that not only prevent fogging but also offer additional benefits such as antimicrobial properties or enhanced barrier characteristics. The integration of smart materials, such as thermochromic or electrochromic compounds, into anti-fogging systems is an area of growing interest, potentially leading to more adaptive and responsive cellophane products.

Existing Anti-Fogging Cellophane Solutions

01 Anti-fogging coatings for cellophane

Various anti-fogging coatings can be applied to cellophane surfaces to prevent condensation and maintain clarity. These coatings typically consist of hydrophilic materials that spread water droplets into a thin, transparent film. Some formulations may include nanoparticles or specific polymers to enhance durability and effectiveness.- Anti-fogging coatings for cellophane: Various anti-fogging coatings can be applied to cellophane surfaces to prevent condensation and maintain clarity. These coatings typically consist of hydrophilic materials that spread water droplets into a thin, transparent film. Some formulations may include nanoparticles or specific polymers to enhance durability and effectiveness.

- Surface modification techniques: Surface modification techniques can be employed to impart anti-fogging properties to cellophane. These may include plasma treatment, chemical etching, or grafting of hydrophilic molecules onto the cellophane surface. Such modifications alter the surface energy and wettability of the material, preventing fog formation.

- Incorporation of anti-fogging agents: Anti-fogging agents can be incorporated directly into the cellophane material during manufacturing. These additives migrate to the surface over time, providing long-lasting anti-fogging properties. Common agents include glycerol derivatives, polyethylene glycol, and certain surfactants.

- Multilayer cellophane structures: Multilayer cellophane structures can be designed with an anti-fogging layer. This approach involves laminating or co-extruding a thin layer of anti-fog material with the base cellophane. The anti-fog layer may contain hydrophilic polymers or be treated with anti-fogging agents.

- Nanostructured cellophane surfaces: Creating nanostructured surfaces on cellophane can impart anti-fogging properties. These structures can be achieved through various methods such as nanoimprinting, etching, or deposition of nanoparticles. The resulting surface topography affects water droplet behavior, preventing fog formation.

02 Surface modification techniques

Cellophane surfaces can be modified through physical or chemical treatments to impart anti-fogging properties. These techniques may include plasma treatment, UV irradiation, or chemical etching to alter the surface energy and create a more hydrophilic surface that resists fogging.Expand Specific Solutions03 Incorporation of anti-fogging agents

Anti-fogging agents can be incorporated directly into the cellophane material during manufacturing. These additives migrate to the surface over time, providing long-lasting anti-fogging properties. Common agents include glycerol derivatives, polyethylene glycol, and certain surfactants.Expand Specific Solutions04 Multilayer cellophane structures

Developing multilayer cellophane structures with an anti-fogging layer can provide enhanced performance. This approach allows for the optimization of both the base cellophane properties and the anti-fogging characteristics, potentially improving durability and effectiveness compared to surface treatments alone.Expand Specific Solutions05 Nanostructured cellophane surfaces

Creating nanostructured surfaces on cellophane can impart anti-fogging properties through physical means. These structures can be created through various methods such as nanoimprinting or controlled etching, resulting in a surface that prevents the formation of visible water droplets and maintains clarity.Expand Specific Solutions

Key Players in Anti-Fogging Packaging Industry

The development of robust anti-fogging cellophane is currently in a growth phase, with increasing market demand driven by various industries such as food packaging, automotive, and electronics. The global market size for anti-fogging films is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like AGC, Inc., Nippon Sheet Glass Co., Ltd., and Central Glass Co., Ltd. leading innovation in Japan. These firms are leveraging their expertise in glass and chemical technologies to develop advanced anti-fogging solutions. Meanwhile, companies like Hutchinson SA and Chery Automobile Co., Ltd. are exploring applications in the automotive sector, indicating a broadening of the technology's use cases across industries.

AGC, Inc. (Japan)

Technical Solution: AGC has developed an innovative anti-fogging cellophane using a hydrophilic coating technology. Their approach involves applying a thin, transparent layer of hydrophilic material to the cellophane surface. This coating contains specially designed polymers that attract water molecules, preventing them from forming droplets that cause fogging. The coating is applied through a proprietary vapor deposition process, ensuring uniform coverage and durability[1]. AGC's anti-fogging cellophane maintains its effectiveness even after repeated use and cleaning, with the coating integrated into the cellophane structure rather than being a separate layer[3]. The company has also incorporated nanoparticles into the coating to enhance its anti-fogging properties and increase its resistance to scratching and environmental factors[5].

Strengths: Long-lasting effectiveness, integrated coating for durability, and enhanced scratch resistance. Weaknesses: Potentially higher production costs due to specialized coating process and materials.

Nippon Sheet Glass Co., Ltd.

Technical Solution: Nippon Sheet Glass has developed a robust anti-fogging cellophane using a multi-layer approach. Their technology involves sandwiching a specially formulated anti-fog layer between two protective cellophane layers. The anti-fog layer is composed of hygroscopic polymers that absorb moisture before it can condense on the surface[2]. This multi-layer structure not only prevents fogging but also enhances the overall strength and durability of the cellophane. The company has further improved the technology by incorporating UV-resistant additives into the outer layers, extending the lifespan of the anti-fogging properties when exposed to sunlight[4]. Nippon Sheet Glass's cellophane also features a self-healing property, where minor scratches on the surface can be repaired through heat activation, maintaining its anti-fogging effectiveness over time[6].

Strengths: Multi-layer protection, UV-resistance, and self-healing properties. Weaknesses: Potentially thicker than single-layer solutions, which may affect flexibility in some applications.

Core Innovations in Anti-Fogging Materials

Anti-Fogging Coating Solution and Anti-Fogging Article

PatentInactiveUS20080207797A1

Innovation

- An anti-fogging coating solution comprising a homopolymer or copolymer with specific repeating units and a crosslinking agent, such as blocked isocyanate or polyfunctional organic silicon compounds, to create a crosslinked film with enhanced scratch resistance, initial anti-fogging property, and retainability.

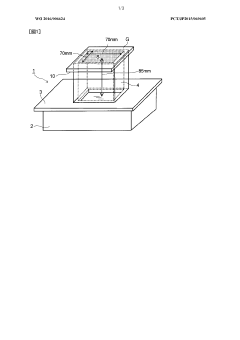

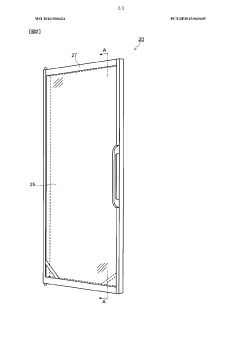

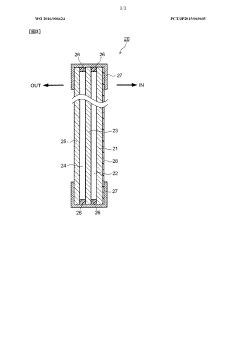

Antifogging film and door for refrigerated showcase

PatentWO2016006624A1

Innovation

- An anti-fogging film with a water-absorbing layer made of cured epoxy resin, containing nitrogen and silicon, directly applied to a resin film, providing extended anti-fogging time and improved peeling resistance without the need for an undercoat layer, ensuring excellent water absorption and durability.

Environmental Impact of Anti-Fogging Cellophane

The development and widespread use of anti-fogging cellophane have significant environmental implications that warrant careful consideration. While this innovative material offers numerous benefits in various applications, its production, use, and disposal can impact the environment in multiple ways.

The manufacturing process of anti-fogging cellophane typically involves the use of chemical additives and coatings to achieve the desired anti-fogging properties. These chemicals may include surfactants, hydrophilic polymers, or nanoparticles, which can potentially contribute to water and soil pollution if not properly managed during production. Additionally, the energy consumption and greenhouse gas emissions associated with the manufacturing process should be taken into account when assessing the overall environmental footprint of anti-fogging cellophane.

One of the primary environmental advantages of anti-fogging cellophane is its potential to reduce food waste. By maintaining clarity and preventing condensation on packaging, this material can extend the shelf life of perishable goods, thereby reducing the amount of food that spoils and is discarded. This reduction in food waste can lead to decreased methane emissions from landfills and a more efficient use of agricultural resources.

However, the disposal of anti-fogging cellophane presents environmental challenges. Like traditional cellophane, it is not easily biodegradable and can persist in the environment for extended periods. Improper disposal can contribute to plastic pollution in terrestrial and aquatic ecosystems, potentially harming wildlife and disrupting natural habitats. The presence of anti-fogging additives may further complicate recycling processes, potentially limiting the material's recyclability.

To mitigate these environmental concerns, research efforts are focusing on developing more sustainable anti-fogging cellophane alternatives. This includes exploring bio-based materials and environmentally friendly anti-fogging coatings that can maintain the desired functionality while reducing the ecological impact. Additionally, improvements in recycling technologies and infrastructure are being pursued to enhance the recyclability of anti-fogging cellophane and minimize its contribution to plastic waste.

The life cycle assessment of anti-fogging cellophane is crucial for understanding its overall environmental impact. This comprehensive evaluation considers factors such as raw material extraction, production processes, transportation, use phase, and end-of-life disposal. By analyzing these aspects, researchers and manufacturers can identify areas for improvement and develop strategies to enhance the sustainability of anti-fogging cellophane throughout its lifecycle.

In conclusion, while anti-fogging cellophane offers valuable benefits in terms of food preservation and packaging efficiency, its environmental impact remains a complex issue. Balancing the material's functionality with ecological considerations is essential for developing truly sustainable packaging solutions. Continued research and innovation in this field are necessary to address environmental concerns and promote the responsible use of anti-fogging cellophane in various industries.

The manufacturing process of anti-fogging cellophane typically involves the use of chemical additives and coatings to achieve the desired anti-fogging properties. These chemicals may include surfactants, hydrophilic polymers, or nanoparticles, which can potentially contribute to water and soil pollution if not properly managed during production. Additionally, the energy consumption and greenhouse gas emissions associated with the manufacturing process should be taken into account when assessing the overall environmental footprint of anti-fogging cellophane.

One of the primary environmental advantages of anti-fogging cellophane is its potential to reduce food waste. By maintaining clarity and preventing condensation on packaging, this material can extend the shelf life of perishable goods, thereby reducing the amount of food that spoils and is discarded. This reduction in food waste can lead to decreased methane emissions from landfills and a more efficient use of agricultural resources.

However, the disposal of anti-fogging cellophane presents environmental challenges. Like traditional cellophane, it is not easily biodegradable and can persist in the environment for extended periods. Improper disposal can contribute to plastic pollution in terrestrial and aquatic ecosystems, potentially harming wildlife and disrupting natural habitats. The presence of anti-fogging additives may further complicate recycling processes, potentially limiting the material's recyclability.

To mitigate these environmental concerns, research efforts are focusing on developing more sustainable anti-fogging cellophane alternatives. This includes exploring bio-based materials and environmentally friendly anti-fogging coatings that can maintain the desired functionality while reducing the ecological impact. Additionally, improvements in recycling technologies and infrastructure are being pursued to enhance the recyclability of anti-fogging cellophane and minimize its contribution to plastic waste.

The life cycle assessment of anti-fogging cellophane is crucial for understanding its overall environmental impact. This comprehensive evaluation considers factors such as raw material extraction, production processes, transportation, use phase, and end-of-life disposal. By analyzing these aspects, researchers and manufacturers can identify areas for improvement and develop strategies to enhance the sustainability of anti-fogging cellophane throughout its lifecycle.

In conclusion, while anti-fogging cellophane offers valuable benefits in terms of food preservation and packaging efficiency, its environmental impact remains a complex issue. Balancing the material's functionality with ecological considerations is essential for developing truly sustainable packaging solutions. Continued research and innovation in this field are necessary to address environmental concerns and promote the responsible use of anti-fogging cellophane in various industries.

Regulatory Compliance for Food Packaging Materials

Regulatory compliance is a critical aspect of developing robust anti-fogging cellophane for food packaging materials. The food packaging industry is subject to stringent regulations to ensure consumer safety and product integrity. In the context of anti-fogging cellophane, manufacturers must adhere to various national and international standards governing food contact materials.

The primary regulatory bodies overseeing food packaging materials include the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and similar agencies in other countries. These organizations establish guidelines for the composition, manufacturing processes, and testing of food packaging materials to prevent potential contamination or migration of harmful substances into food products.

For anti-fogging cellophane, compliance with FDA regulations is essential for products intended for the U.S. market. The FDA's Code of Federal Regulations (CFR) Title 21, particularly parts 174-179, outlines the requirements for indirect food additives, including those used in packaging materials. Manufacturers must ensure that all components of the anti-fogging cellophane, including the base material and any additives, are listed as Generally Recognized as Safe (GRAS) or have received prior approval from the FDA.

In the European Union, Regulation (EC) No 1935/2004 provides the overarching framework for materials and articles intended to come into contact with food. This regulation is supplemented by specific measures, such as Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food. Compliance with these regulations involves demonstrating that the anti-fogging cellophane does not release substances into food at levels that could endanger human health or change the composition, taste, or odor of the food.

Manufacturers must also consider global harmonization efforts, such as those led by the Global Food Safety Initiative (GFSI), which aims to benchmark food safety standards worldwide. Adhering to GFSI-recognized schemes can facilitate compliance with multiple regional regulations and enhance market access.

To ensure regulatory compliance, manufacturers of anti-fogging cellophane must implement rigorous quality control measures and conduct extensive testing. This includes migration testing to assess the potential transfer of substances from the packaging to the food, as well as overall migration limits (OML) and specific migration limits (SML) for individual substances. Documentation of compliance, including test results and declarations of conformity, must be maintained and made available to regulatory authorities upon request.

Furthermore, as environmental concerns gain prominence, regulations regarding the recyclability and biodegradability of packaging materials are becoming increasingly relevant. Manufacturers must consider these aspects in the development of anti-fogging cellophane to ensure compliance with emerging sustainability regulations and meet consumer expectations for eco-friendly packaging solutions.

The primary regulatory bodies overseeing food packaging materials include the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and similar agencies in other countries. These organizations establish guidelines for the composition, manufacturing processes, and testing of food packaging materials to prevent potential contamination or migration of harmful substances into food products.

For anti-fogging cellophane, compliance with FDA regulations is essential for products intended for the U.S. market. The FDA's Code of Federal Regulations (CFR) Title 21, particularly parts 174-179, outlines the requirements for indirect food additives, including those used in packaging materials. Manufacturers must ensure that all components of the anti-fogging cellophane, including the base material and any additives, are listed as Generally Recognized as Safe (GRAS) or have received prior approval from the FDA.

In the European Union, Regulation (EC) No 1935/2004 provides the overarching framework for materials and articles intended to come into contact with food. This regulation is supplemented by specific measures, such as Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food. Compliance with these regulations involves demonstrating that the anti-fogging cellophane does not release substances into food at levels that could endanger human health or change the composition, taste, or odor of the food.

Manufacturers must also consider global harmonization efforts, such as those led by the Global Food Safety Initiative (GFSI), which aims to benchmark food safety standards worldwide. Adhering to GFSI-recognized schemes can facilitate compliance with multiple regional regulations and enhance market access.

To ensure regulatory compliance, manufacturers of anti-fogging cellophane must implement rigorous quality control measures and conduct extensive testing. This includes migration testing to assess the potential transfer of substances from the packaging to the food, as well as overall migration limits (OML) and specific migration limits (SML) for individual substances. Documentation of compliance, including test results and declarations of conformity, must be maintained and made available to regulatory authorities upon request.

Furthermore, as environmental concerns gain prominence, regulations regarding the recyclability and biodegradability of packaging materials are becoming increasingly relevant. Manufacturers must consider these aspects in the development of anti-fogging cellophane to ensure compliance with emerging sustainability regulations and meet consumer expectations for eco-friendly packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!