Electrical terminal

a technology of electric terminals and terminals, which is applied in the direction of contact members penetrating/cutting insulation/cable strands, electrical appliances, fastening/insulating connecting parts, etc., can solve the problems of large cross section, large volume, and limited construction type of conventional terminals, and achieve simple and thus economical production. , the effect of simple manual opening of the clamping si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

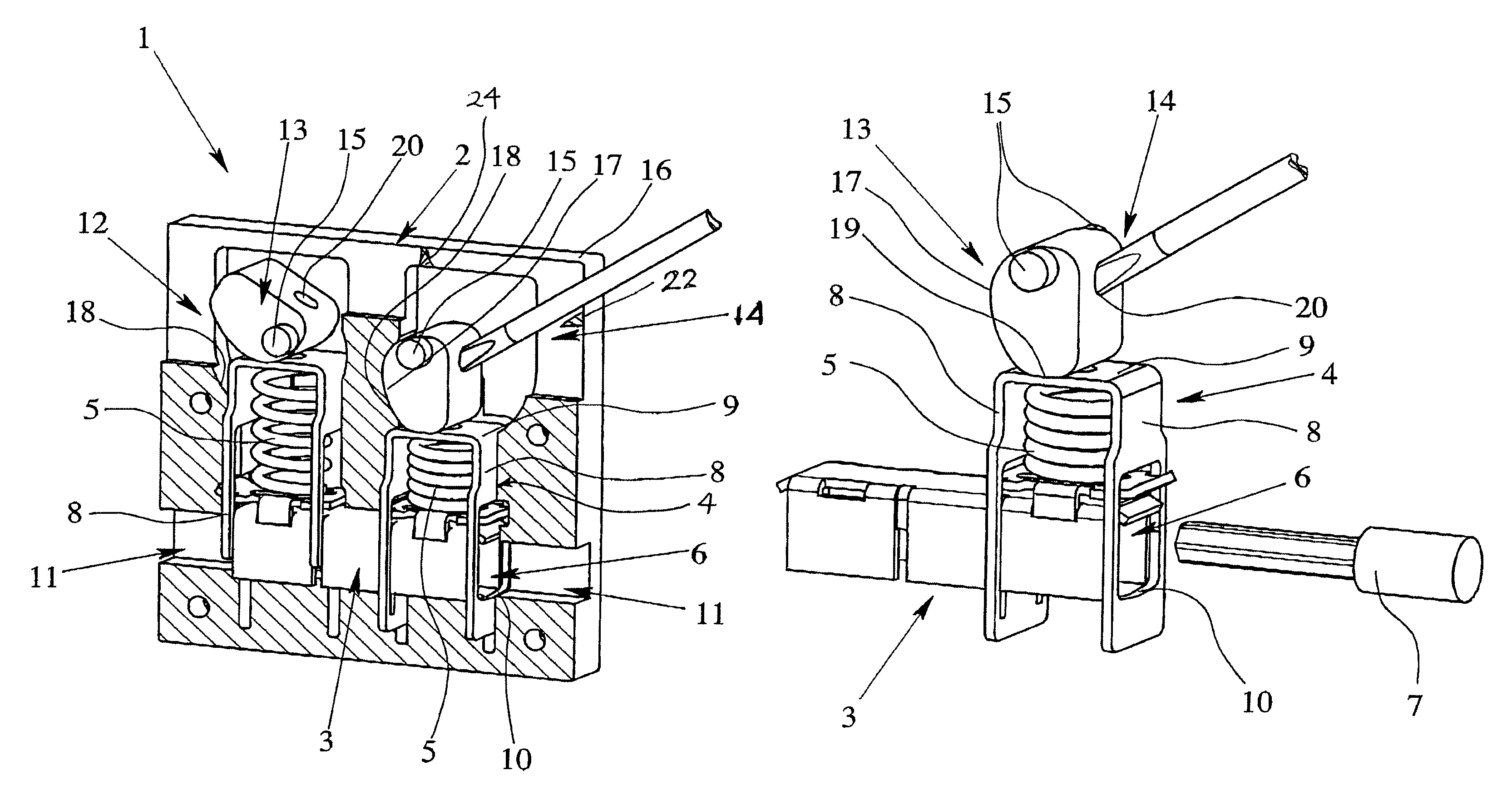

[0021]FIG. 1 shows an electrical terminal 1 with an insulating housing 2, a conductor bar 3 located in the insulating housing 2, and two strain-relief clamp connections. The two strain relief clamp connections each have a generally U-shaped strain-relief clamp 4 and a helical compression spring 5 located within the strain-relief clamp 4. As is especially apparent from FIGS. 2 and 3, the strain-relief clamp 4 has two clamping legs 8 that each have one through opening 6 for inserting an electric lead 7 to be electrically connected, and a U-shaped back 9 that connects the clamping legs 8 to one another. The conductor bar 3 is inserted into the through openings 6 of the strain-relief clamp 4 so that the through openings 6 surround the conductor bar 3.

[0022]The compression spring 5 is located between the U-shaped back 9 of the strain-relief clamp 4 and the conductor bar 3 such that the compression spring 5 pulls the lower edge 10 of the through opening 6 against the conductor bar 3, i.e....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com