Bolt driven connector

a connector and bolt technology, applied in the direction of connection, electrical apparatus, coupling device connection, etc., can solve the problems of insufficient insertion of first terminal fitting, inability to move the tpa member to the full locking position, etc., to prevent or limit the movement of the nu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

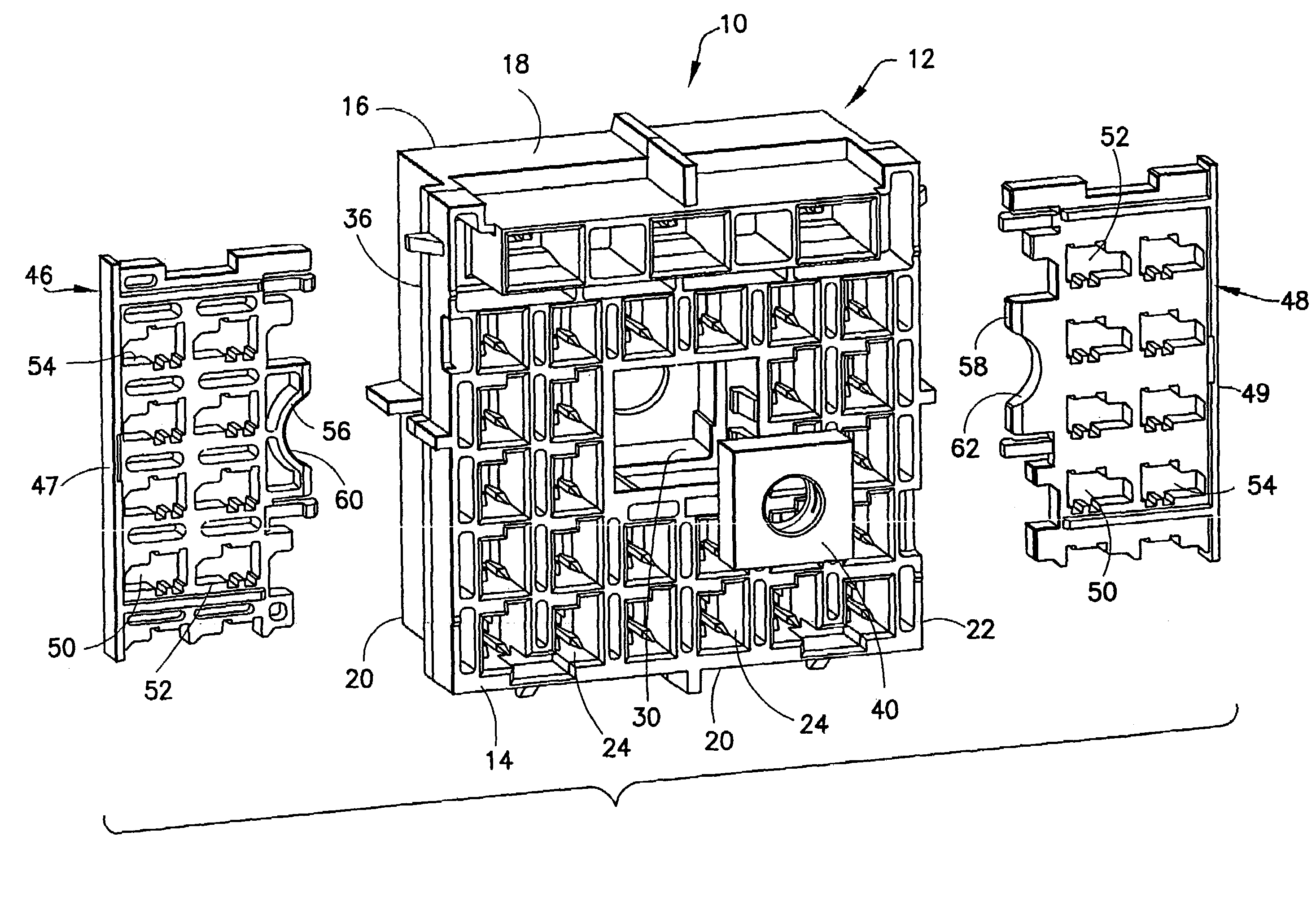

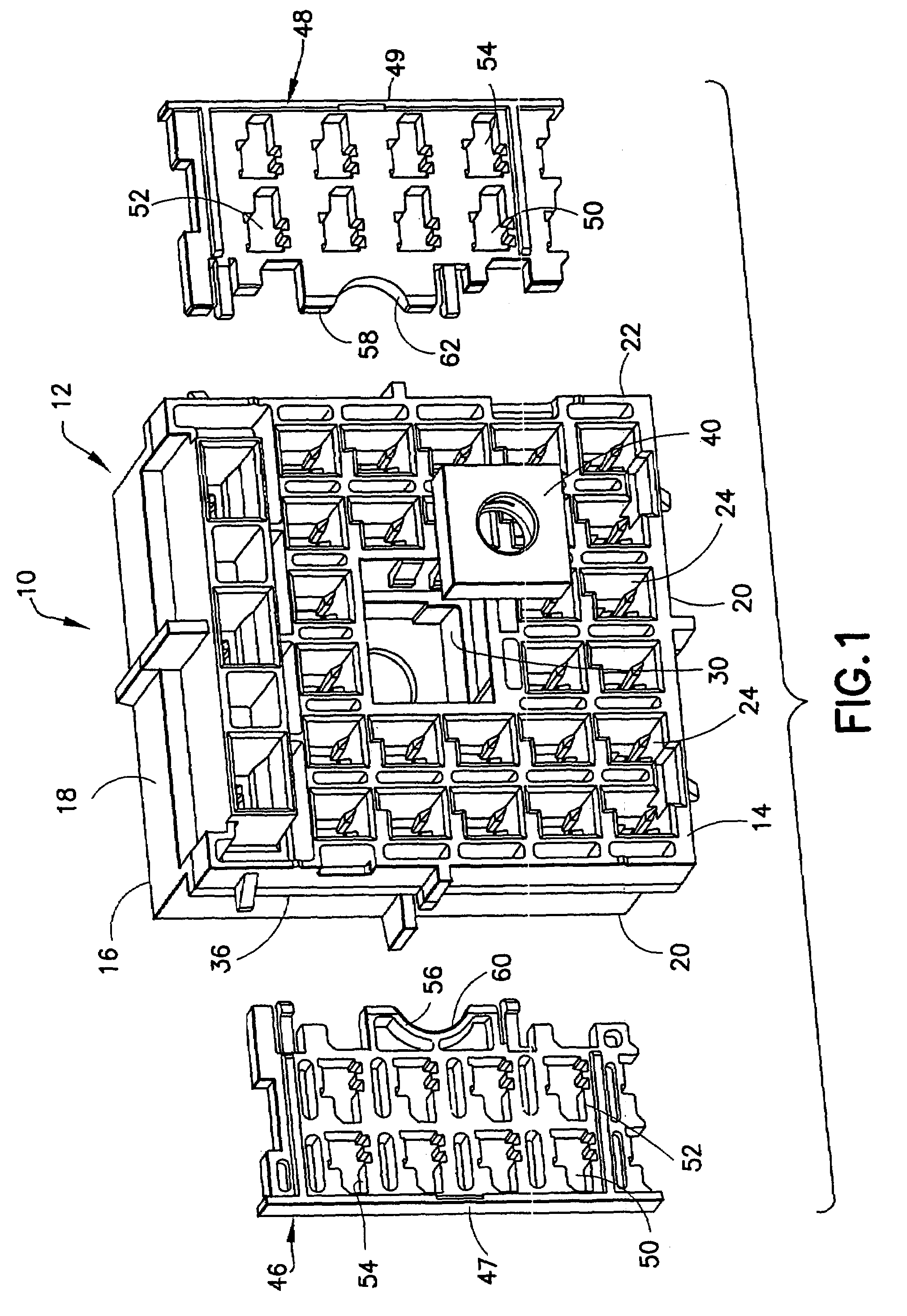

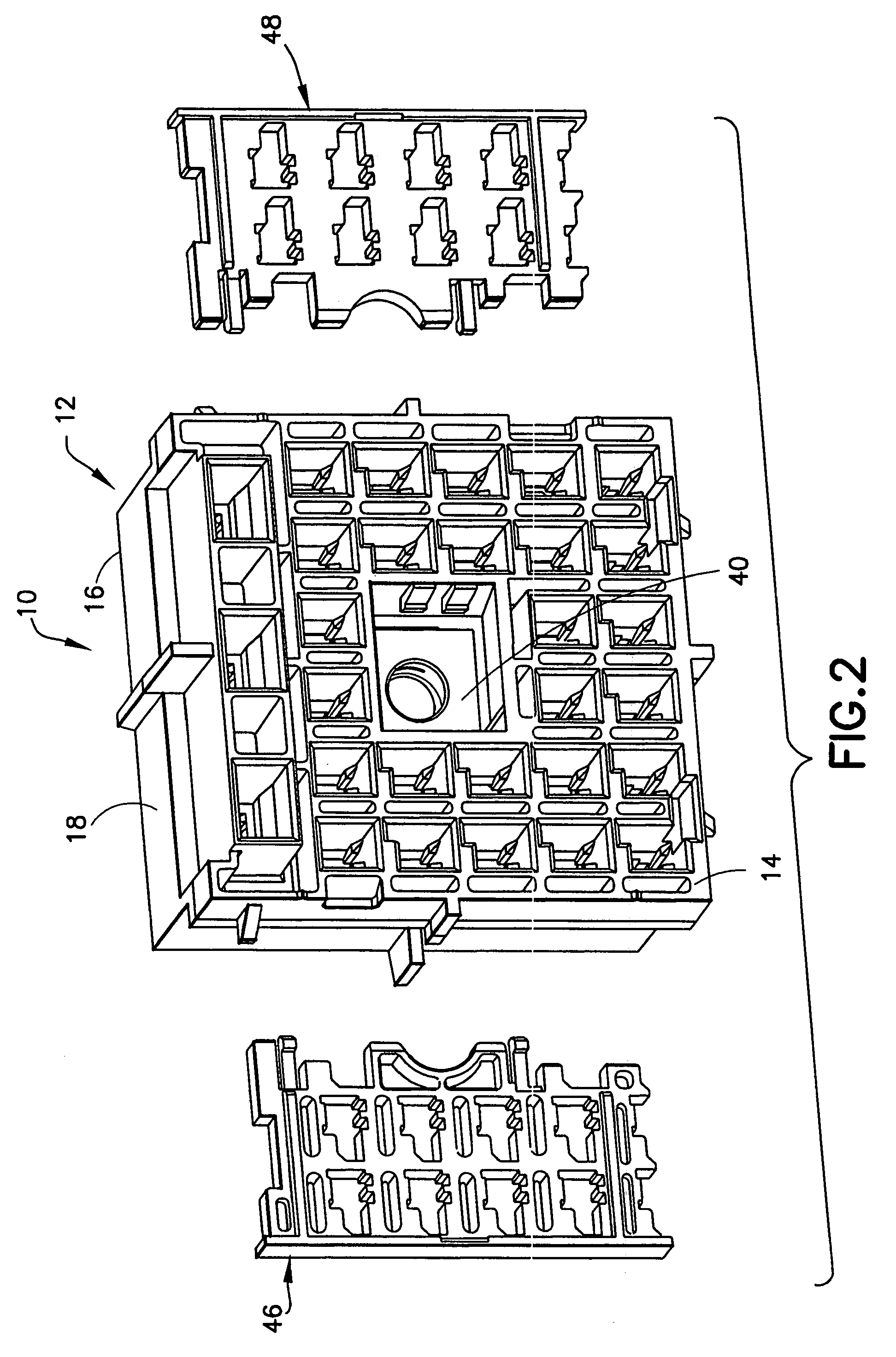

[0027]A bolt driven connector assembly in accordance with the invention is identified by the numeral 10 in FIGS. 1-5. The connector assembly 10 includes a housing 12 that is molded unitarily from a non-conductive synthetic resin. The housing 12 has a substantially rectilinear block shape with opposite rear and front ends 14 and 16 respectively. The rear end 14 of the housing 12 is configured for connection with a mating housing (not shown). Opposite top and bottom walls 18 and 20 extend from the rear end 14 to the front end 16 of the housing 12. The terms top and bottom are used herein as a convenient frame of reference, and do not imply a required gravitational frame of reference for the connector 10. Opposite first and second side walls 20 and 22 also extend between the rear and front ends 14 and 16 of the housing 12 and connect the top and bottom walls 18 and 20.

[0028]Cavities 24 extend through the housing 12 along direction A from the rear end 16 substantially to the rear end 14...

second embodiment

[0039]FIGS. 6-10 show a connector assembly 70 in accordance with the invention. The connector assembly 70 includes a housing 72 that is molded unitarily from a non-conductive synthetic resin. The housing 72 has a substantially rectilinear block shape with opposite front and rear ends 74 and 76 respectively. The front end 74 of the housing 72 is configured for connection with a mating housing (not shown). Opposite top and bottom walls 78 and 80 extend from the front end 74 to the rear end 76 of the housing 72. The terms top and bottom are used herein as a convenient frame of reference, and do not imply a required gravitational frame of reference for the connector 70. Opposite first and second side walls 82 and 84 also extend between the front and rear ends 74 and 76 of the housing 82 and connect the top and bottom walls 78 and 80.

[0040]Cavities 85 extend through the housing 72 along direction “A” from the rear end 76 substantially to the front end 74. The cavities 85 are configured t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com