Drive control device of motor and disk rotation system

a technology of drive control and control device, which is applied in the direction of record information storage, instruments, electronic commutators, etc., can solve the problems of speeding up involving an increasing the hard disk drive of such a small diameter is likely to generate the irregularities of rotation, so as to reduce the burden on the microprocessor, reduce the rotational irregularities of the motor depending on individual differences, and reduce the effect of rotating irregularities of the motor due to the variations of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

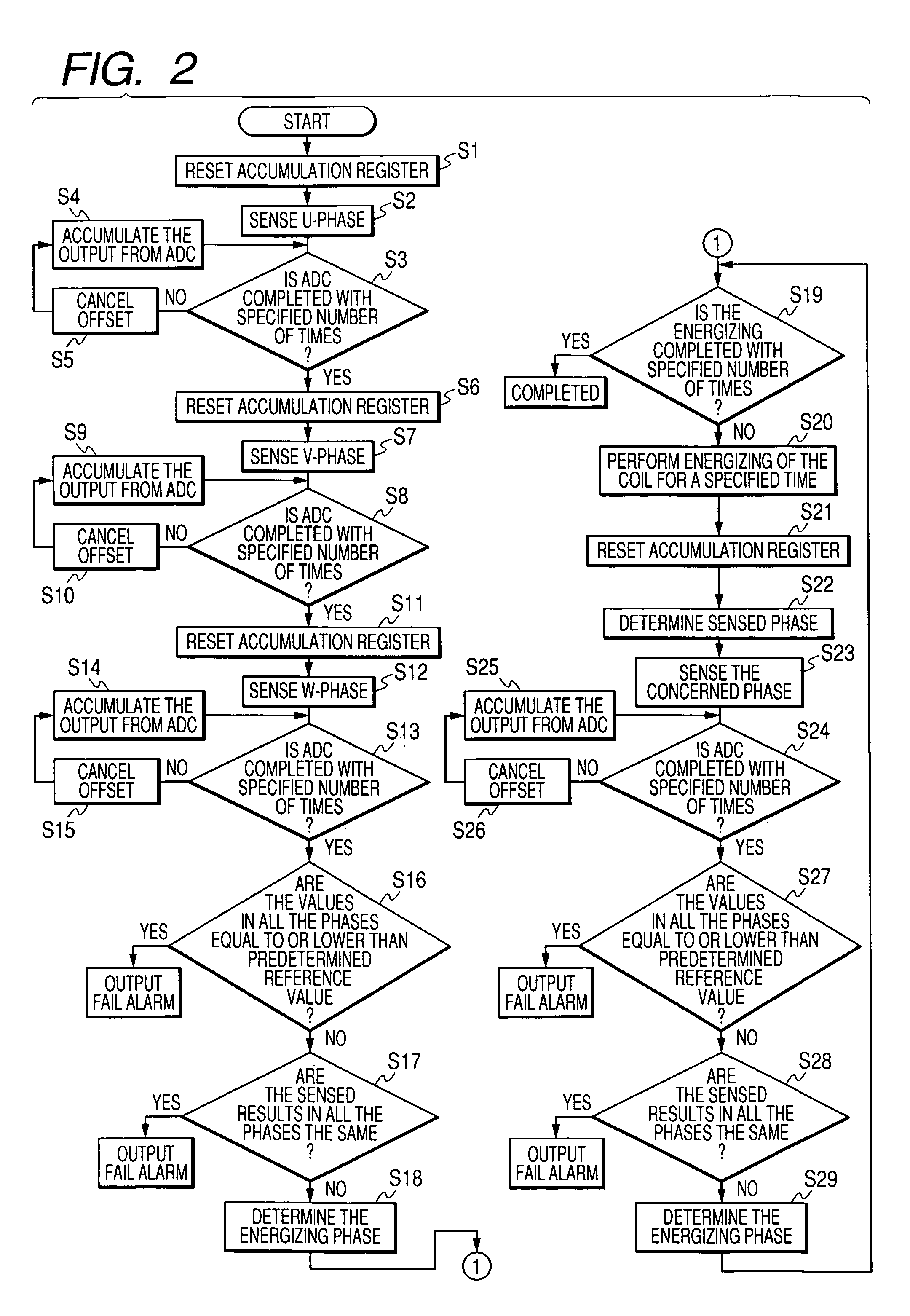

[0034]The preferred embodiments will be described with reference to the accompanying drawings.

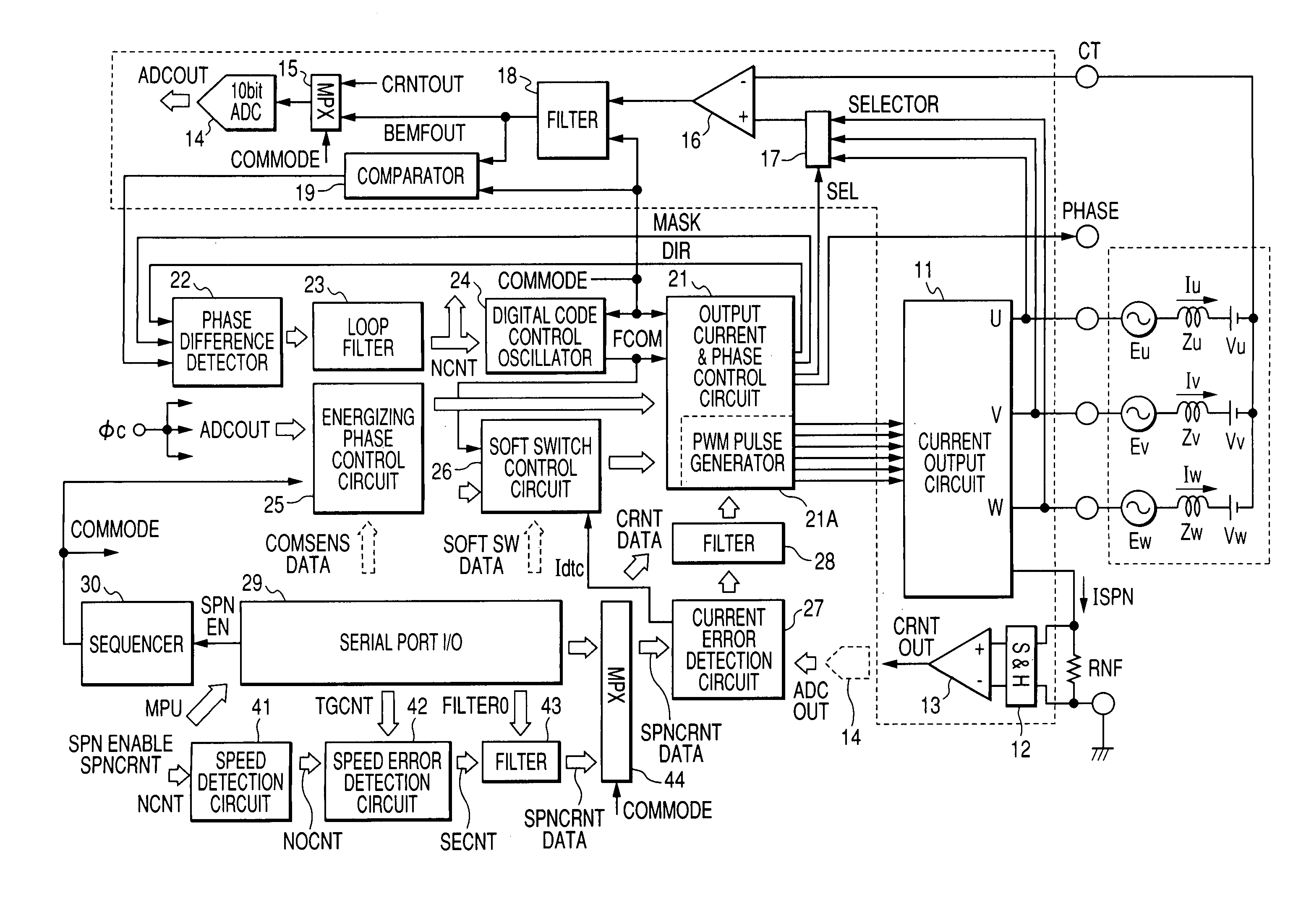

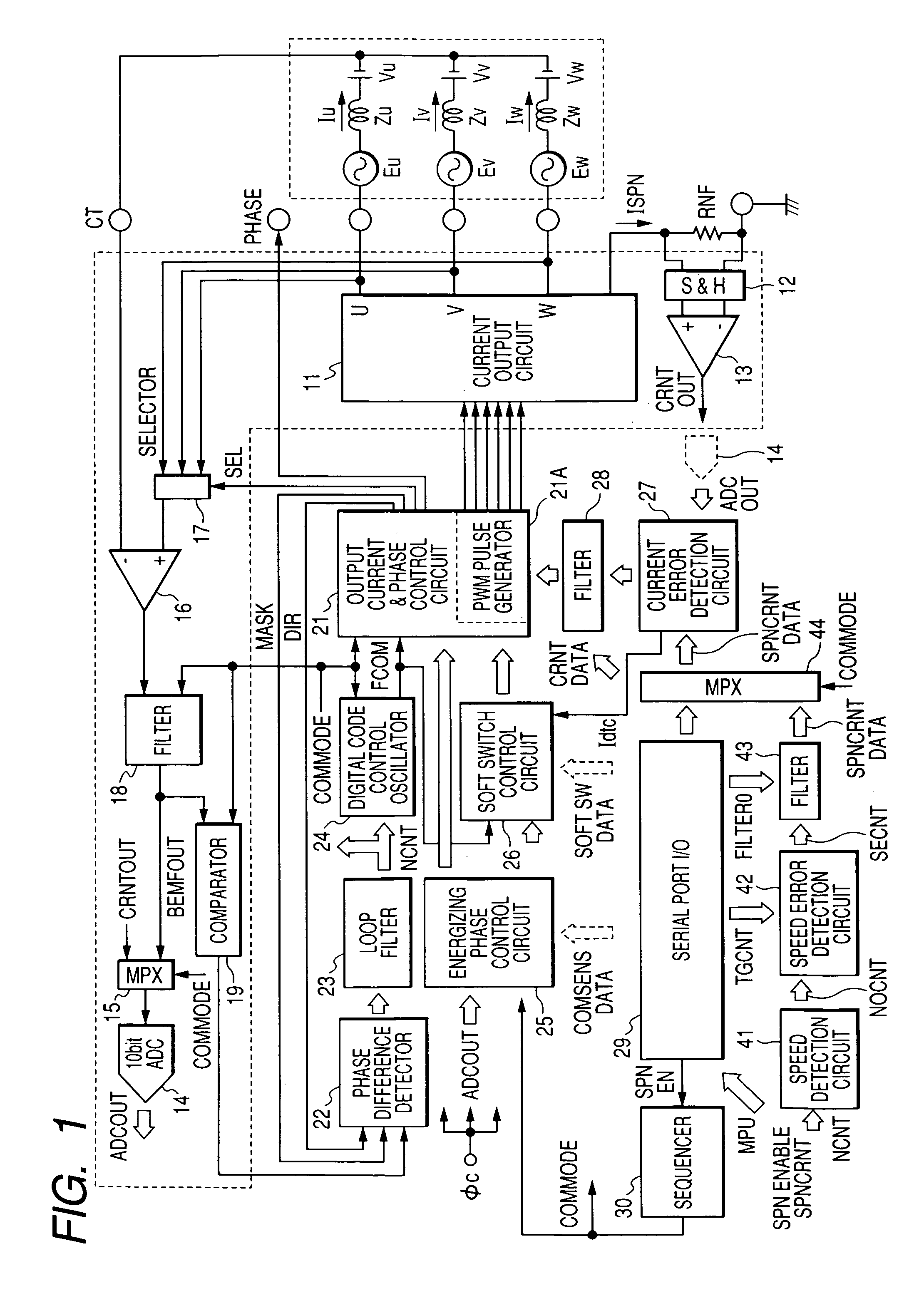

[0035]FIG. 1 illustrates a schematic configuration in which the present invention is applied to a drive control circuit of a three-phase brushless motor used for the spindle motor in a hard disk drive and the like. The circuit illustrated in FIG. 1 is formed on one or several semiconductor substrates of single crystal silicon or the like, except coils Lu, Lv, and Lw of the motor.

[0036]In FIG. 1, a current output circuit 11 sequentially supplies currents to the coils Lu, Lv, and Lw of the three-phase brushless motor. An output current & phase control circuit 21 generates PWM (Pulse Width Modulation) signals for driving output transistors of the current output circuit 11 and controlling output currents, and supplies the PWM signals to the current output circuit 11; and it supplies a selector 17 with a signal SEL for selecting coil terminals that detects back electromotive forces. The symbol R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com