Selective one-way bit-driving apparatus

a one-way, drive-by technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problem that the engagement shaft cannot transmit the torque it needs to be effective, and achieve the effect of reducing the number of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

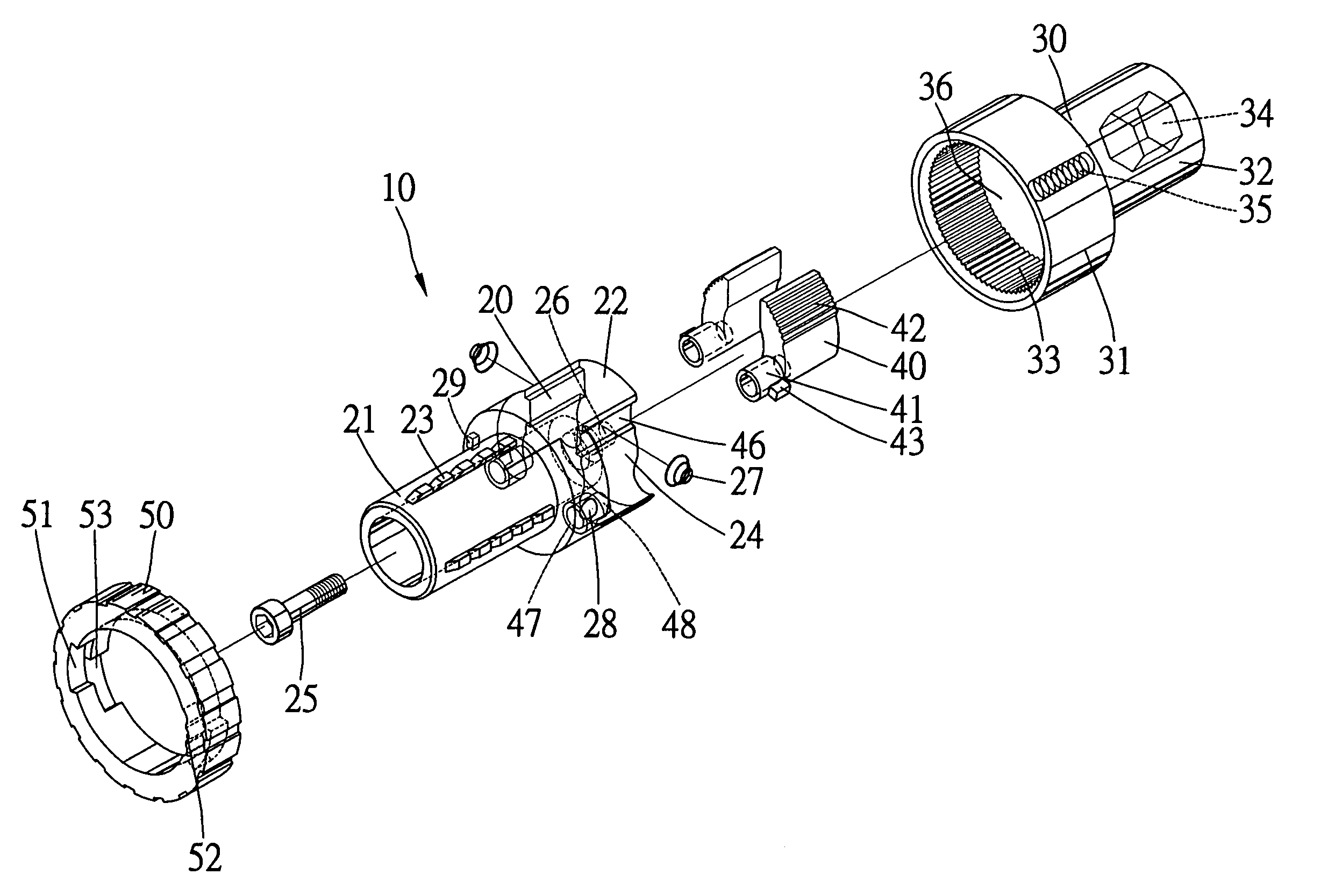

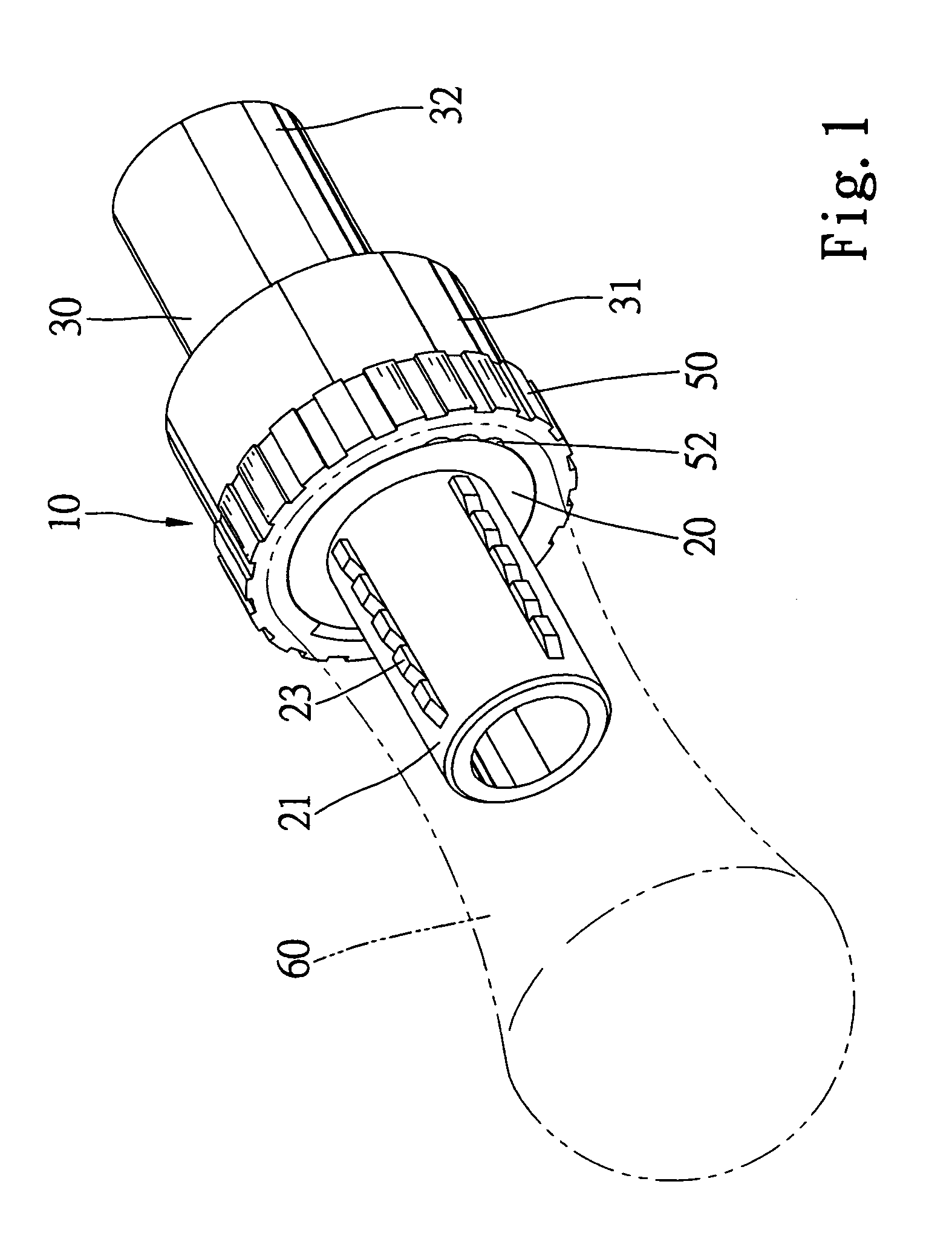

[0017]Referring to FIG. 1, according to a first embodiment of the present invention, a selective one-way bit-driving apparatus 10 is engaged with a handle 60 in order to drive a bit (not shown).

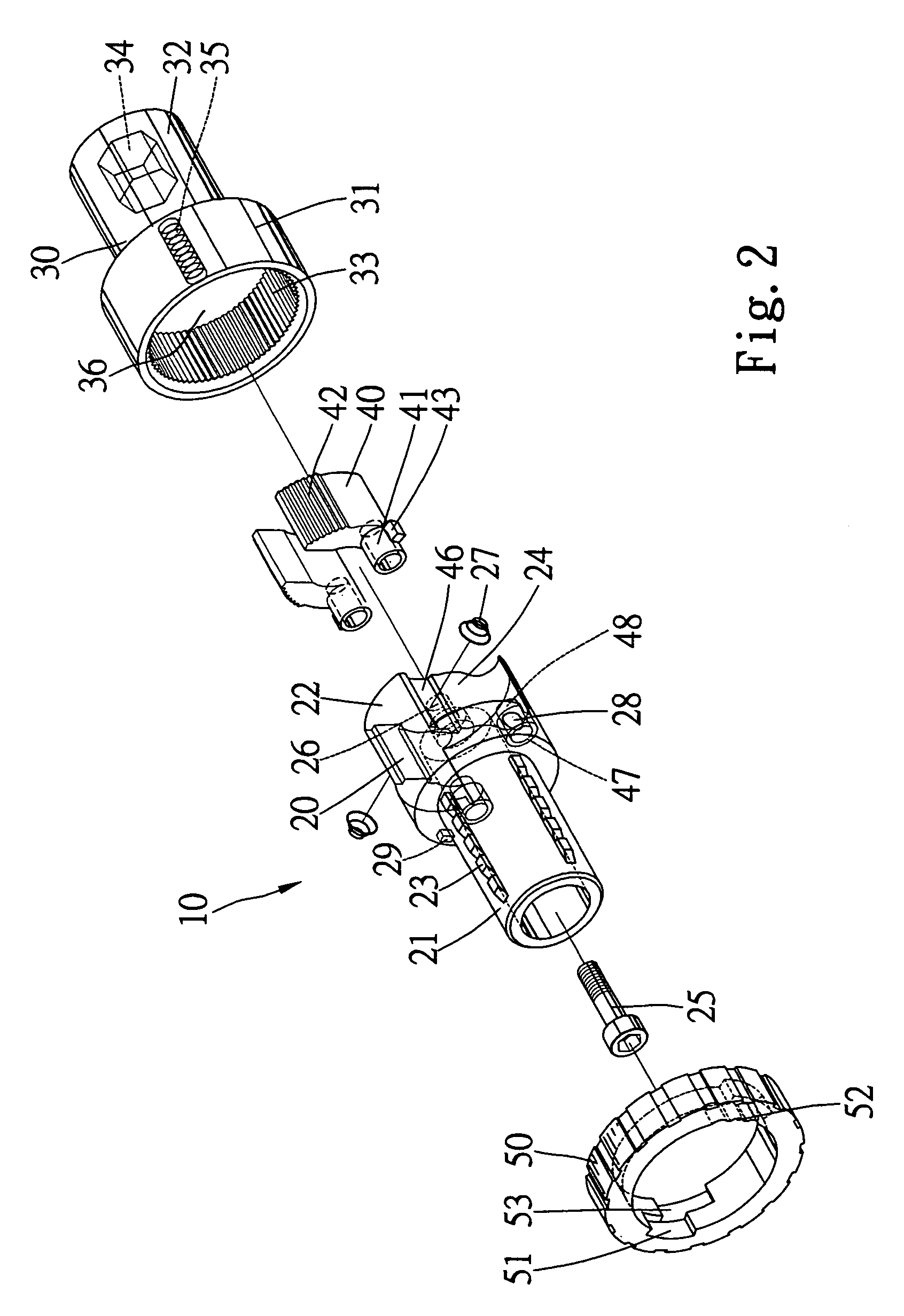

[0018]Referring to FIG. 2, the selective one-way bit-driving apparatus 10 includes a shaft 20 for connection with the handle 60, a bit receiver 30 for receiving the bit, two one-way drivers 40 each enabling the shaft 20 to drive the bit receiver 30 in only one direction and a switch 50 that can be manipulated so as to select one of the one-way drivers 40 for operation.

[0019]Referring to FIGS. 2 and 3, the shaft 20 defines an axial tunnel 26. The shaft 20 includes a first section 21 and a second section 22 with an external diameter greater than that of the first section 21. On the first section 21 are formed four rows of protrusions 23 for holding on to the handle 60 when the first section 21 is inserted in the handle 60. Two recesses 24 are defined in the periphery of the second section 22. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com