Method and mechanism for interactively governing trigger movement and regulating the cyclic firing rate of firearms

a technology of cyclic firing rate and trigger movement, applied in the field of firearms, can solve the problems of increasing the cost and complexity of manufacturing and inventory control, the secondary type of mechanism of the mechanism of the mechanism of the mechanism of the secondary type of the mechanism, and the difficulty of adjusting the trigger position, etc., to achieve enhanced trigger feel and/or trigger tactile sense, and improve the operational management of the firearm trigger movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

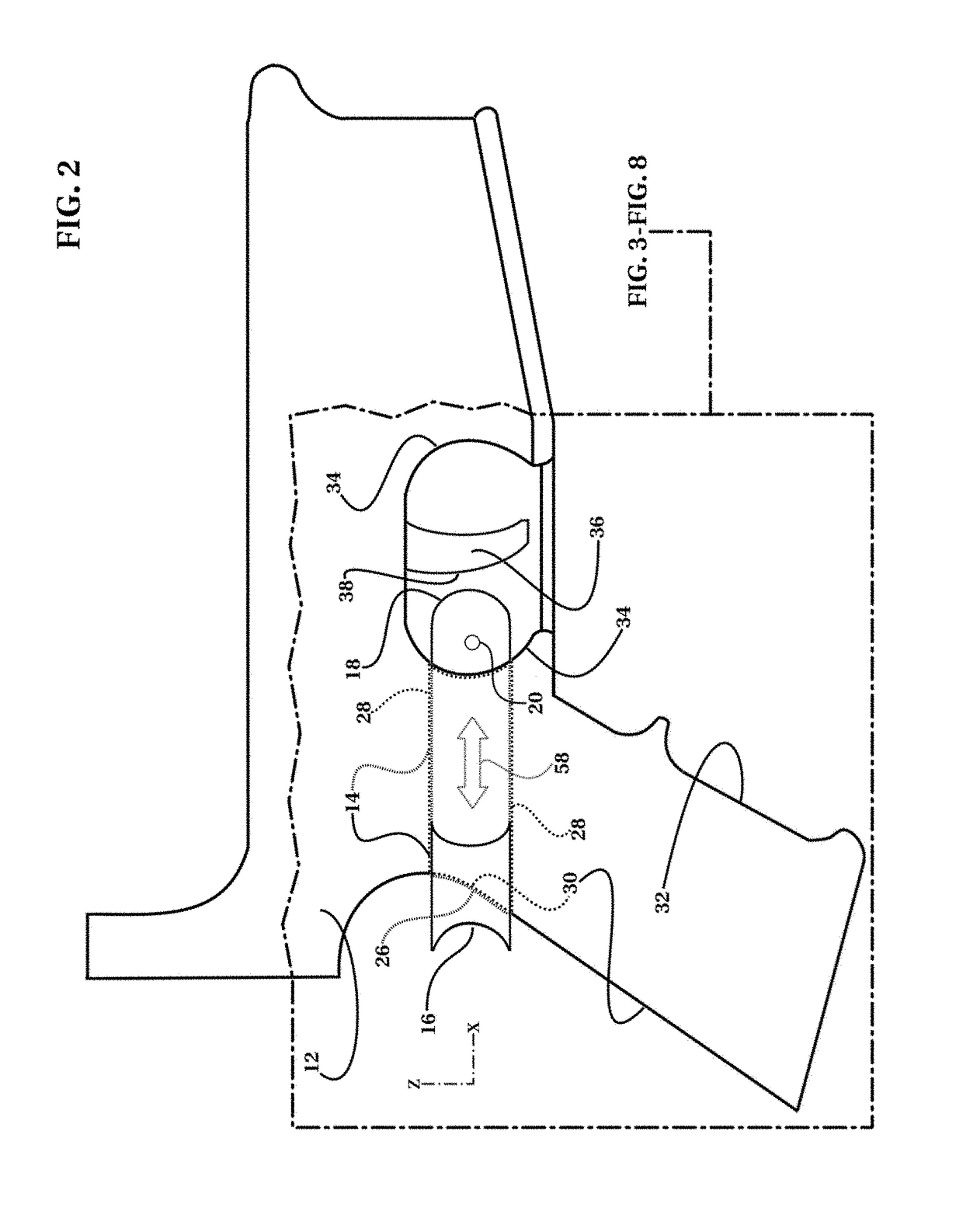

[0098]Referring now to the invention in more detail wherein the figures have like numerals which indicate like or corresponding parts throughout the several views.

[0099]As seen in FIG. 1 on drawing sheet 1 / 18, a serviceable M4 Carbine type firearm 10 is shown schematically in a simplified semitransparent figurative depiction being diagramed in contour outline and perspective view as FIG. 1A.

[0100]In more detail still referring to FIG. 1A, as seen within FIG. 1 on drawing sheet 1 / 18, showing an indicating chain line encompassing in part a figurative one piece lower receiver 12 shown mounted on the M4 Carbine type firearm 10. The figurative one piece lower receiver 12 is linked by single chain line to an enlarged semitransparent perspective view representing the same indicated one piece lower receiver 12 shown as FIG. 1B within the sight region of FIG. 1 as described below. Although the illustrations within FIG. 1 depict a unique one piece lower receiver 12, the majority of AR15 type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com