Tubing anchoring and movement reducing system

a tubing anchoring and movement reduction technology, applied in the field of petroleum well tools, can solve problems such as vibrations within the tubing string, and achieve the effect of reducing or stopping the movement of the tubing string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

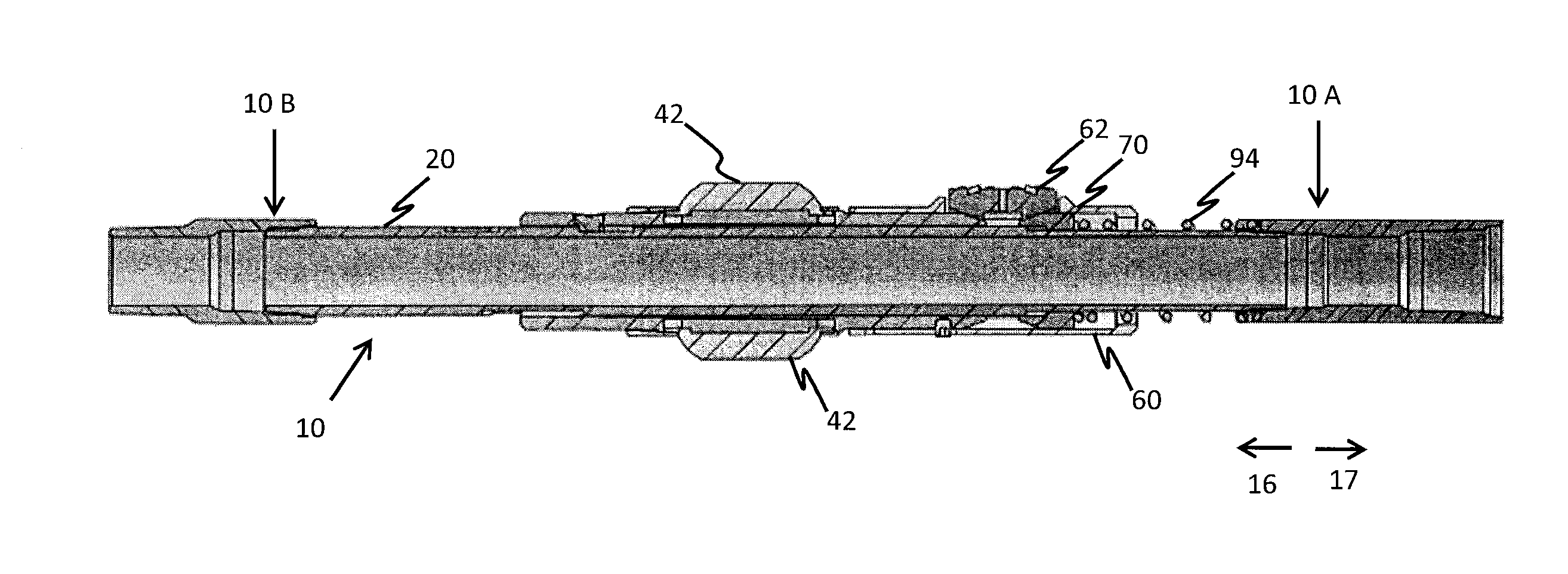

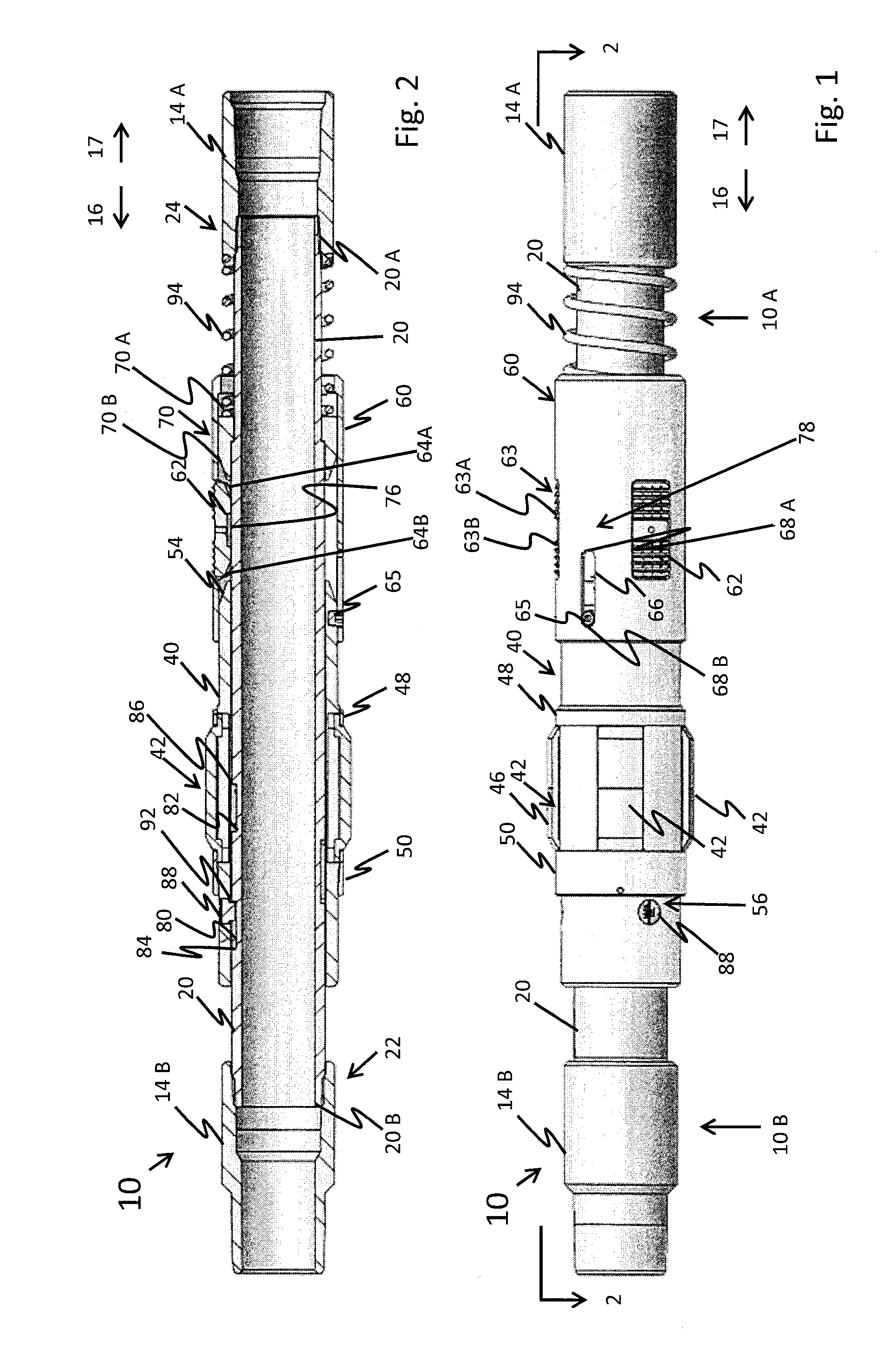

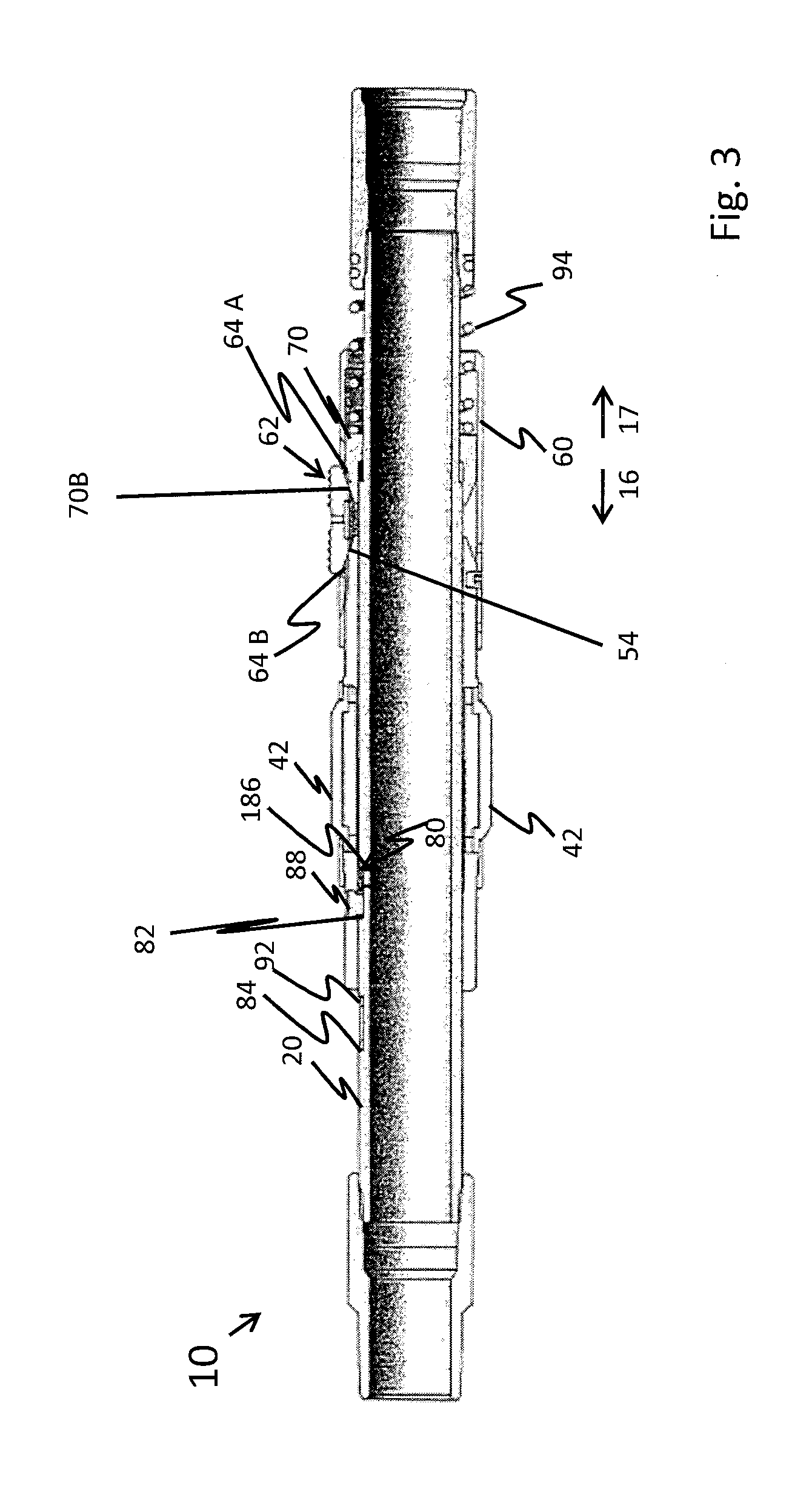

[0034]FIGS. 1 to 8 depict one example embodiment of a ¼ turn tubing anchor catcher 10 for use with an anchoring and movement reducing system 1000, also referred to herein as the system 1000. The phrase “movement reducing system” encompasses at least both concepts of decreasing and completely stopping movement within a well conduit 12 that is caused by an artificial lift pumping system within the system. The ¼ turn tubing anchor catcher 10 may be inserted within the well conduit 12 (see FIGS. 13 and 14), such as a wellbore casing. FIGS. 1 and 2 depict the ¼ turn tubing anchor catcher 10 in an unset, or “run-in”, orientation in which it can be run inside the well conduit 12 on a tubing string. Safety subs 14A, B may be attached to a mandrel 20 of the ¼ turn tubing anchor catcher 10 having attachment means, such as an inner threaded lower end 22 and an outer threaded upper end 24. In this embodiment, the ¼ turn tubing anchor catcher 10 may be run down the well conduit 12 on the tubing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com