Smoking pipe for both tobacco leaves and oil resin

a technology of oil resin and tobacco leaves, which is applied in the direction of tobacco pipes, applications, tobacco, etc., can solve the problems of not being able to be used to smoke liquid tobacco, oil to smoke, and requiring maintenance and care of pipes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The instant invention is for an improved pipe for smoking tobacco that is an improvement over the prior art wherein the improvement allows for the pipe to be used to smoke liquid tobacco.

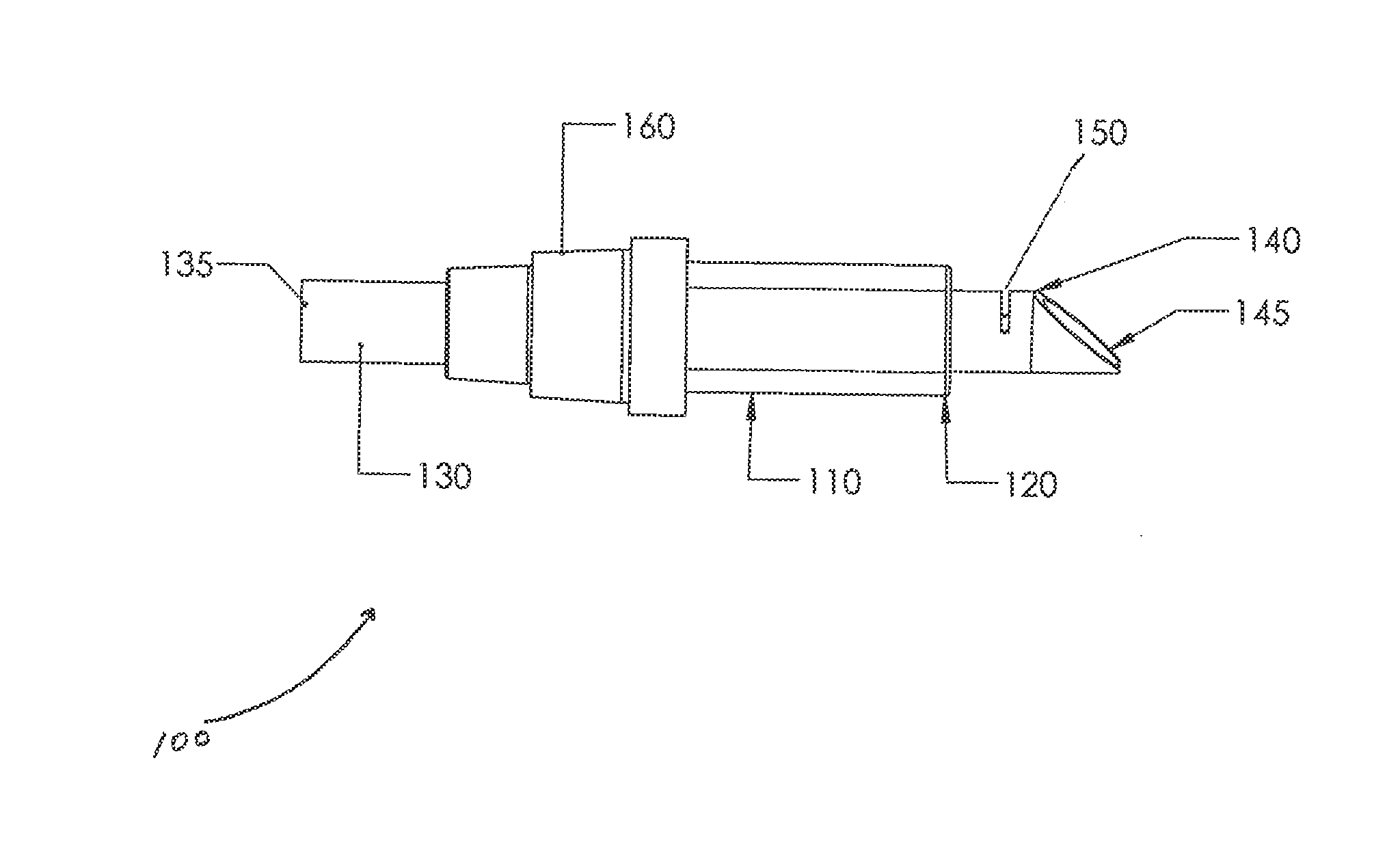

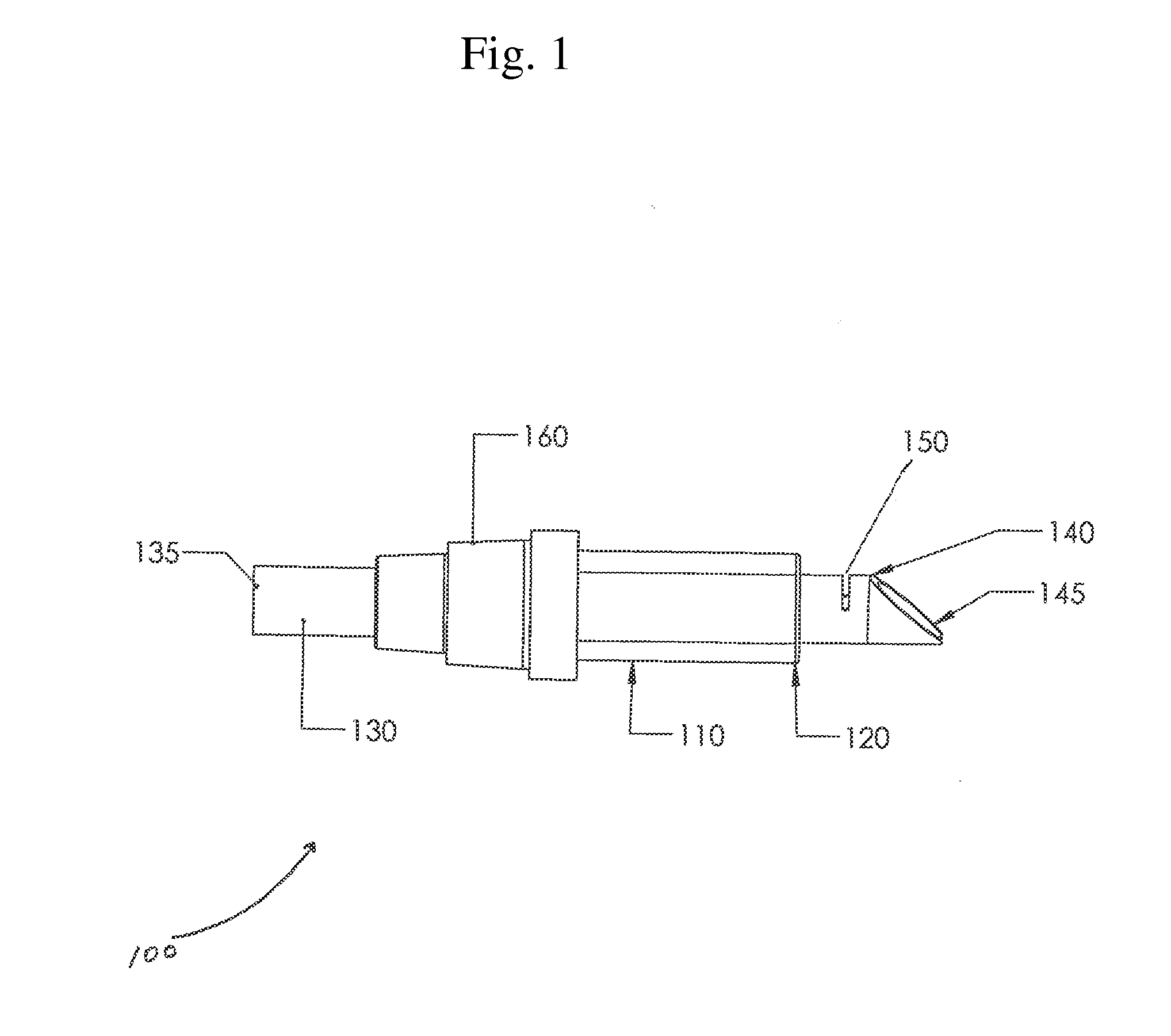

[0019]FIG. 1 shows an embodiment of the invention wherein pipe 100 comprises a retainer 145 extending from a closed end 140 of inner tube 130. With exception of the closed end 140 the inner tube 130 is substantially hollow. Inlet 150 is a hole formed on a side of inner tube 130 that communicates with opening 135. Means 160 connects to a first end of outer tube 110 and slideably engages with the exterior surface of inner tube 130 allowing the inner tube to extend and retract within and relative to outer tube 110. In an embodiment, means 160 comprises an insulating or non-heat conducting material such as rubber which secures an open end 125 of outer tube 110 and creates an airtight seal between the interior of outer tube 110 and the exterior of inner tube 130. As shown in FIG. 1, the retainer 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com