Method for operating a multistage compressor

a multi-stage compressor and multi-stage technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of unfavorable limiting the available comparatively large safety gaps, and over-noise of the turbo compressor, so as to increase the operating range of the turbo compressor and prevent over-noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

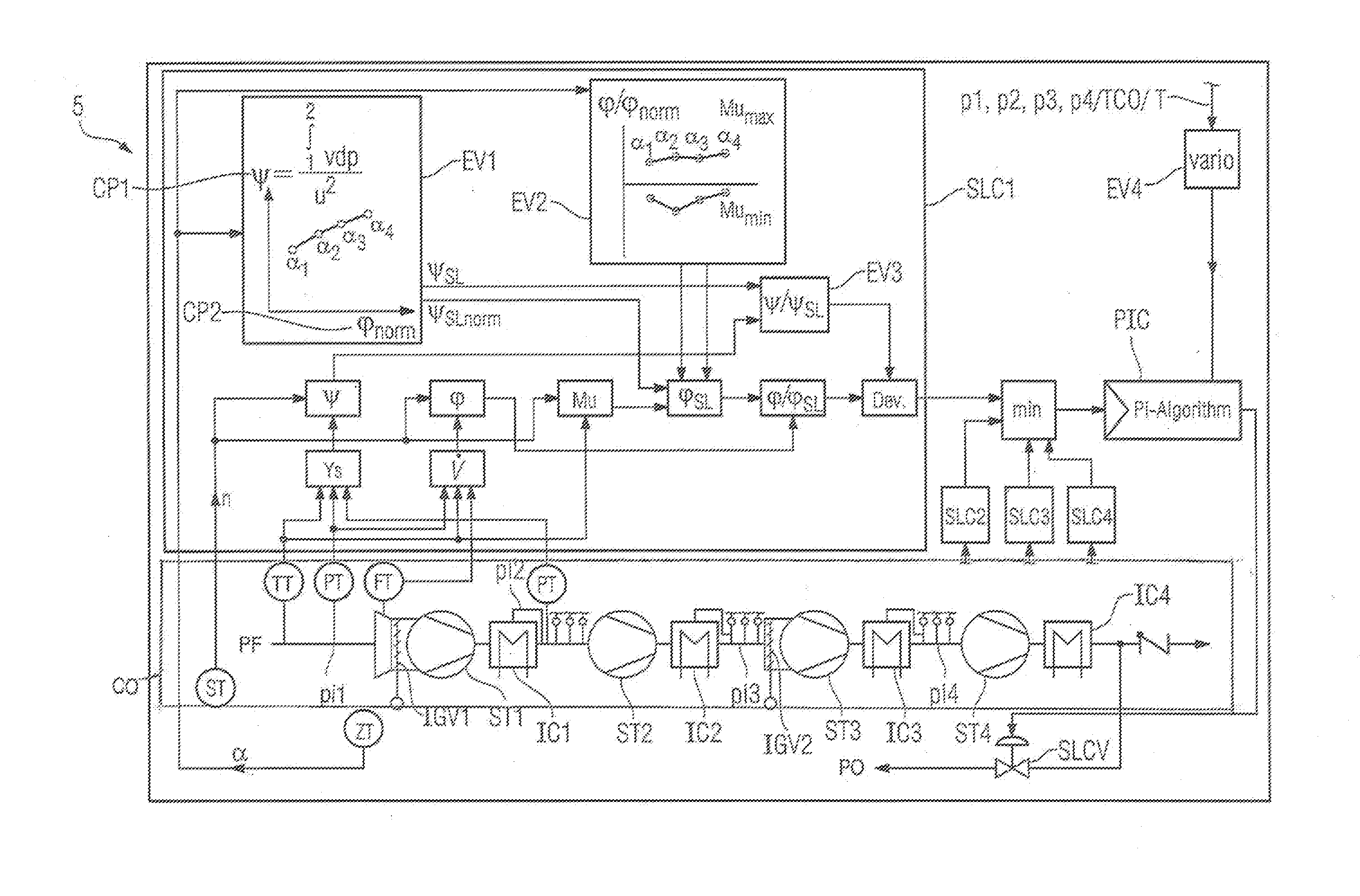

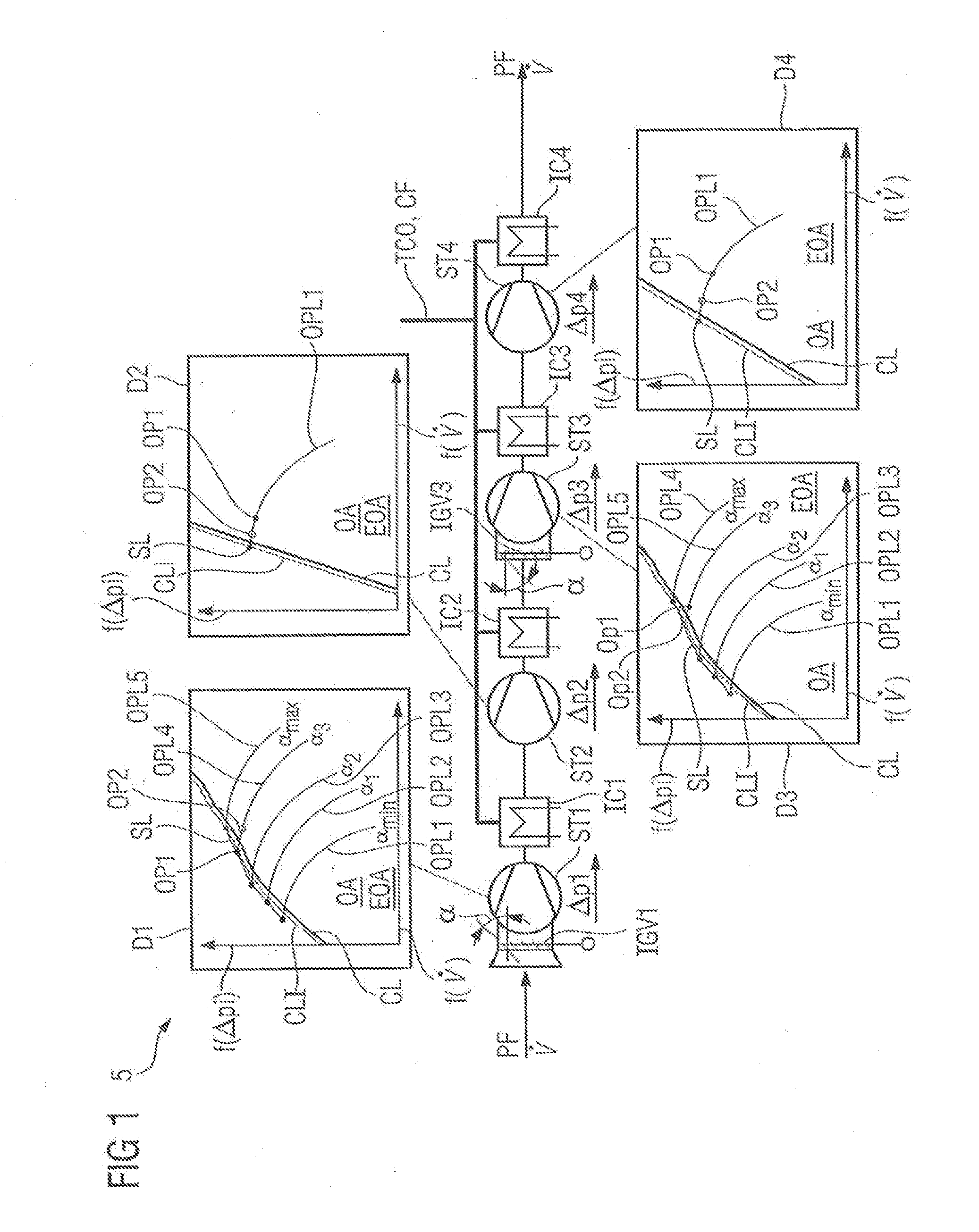

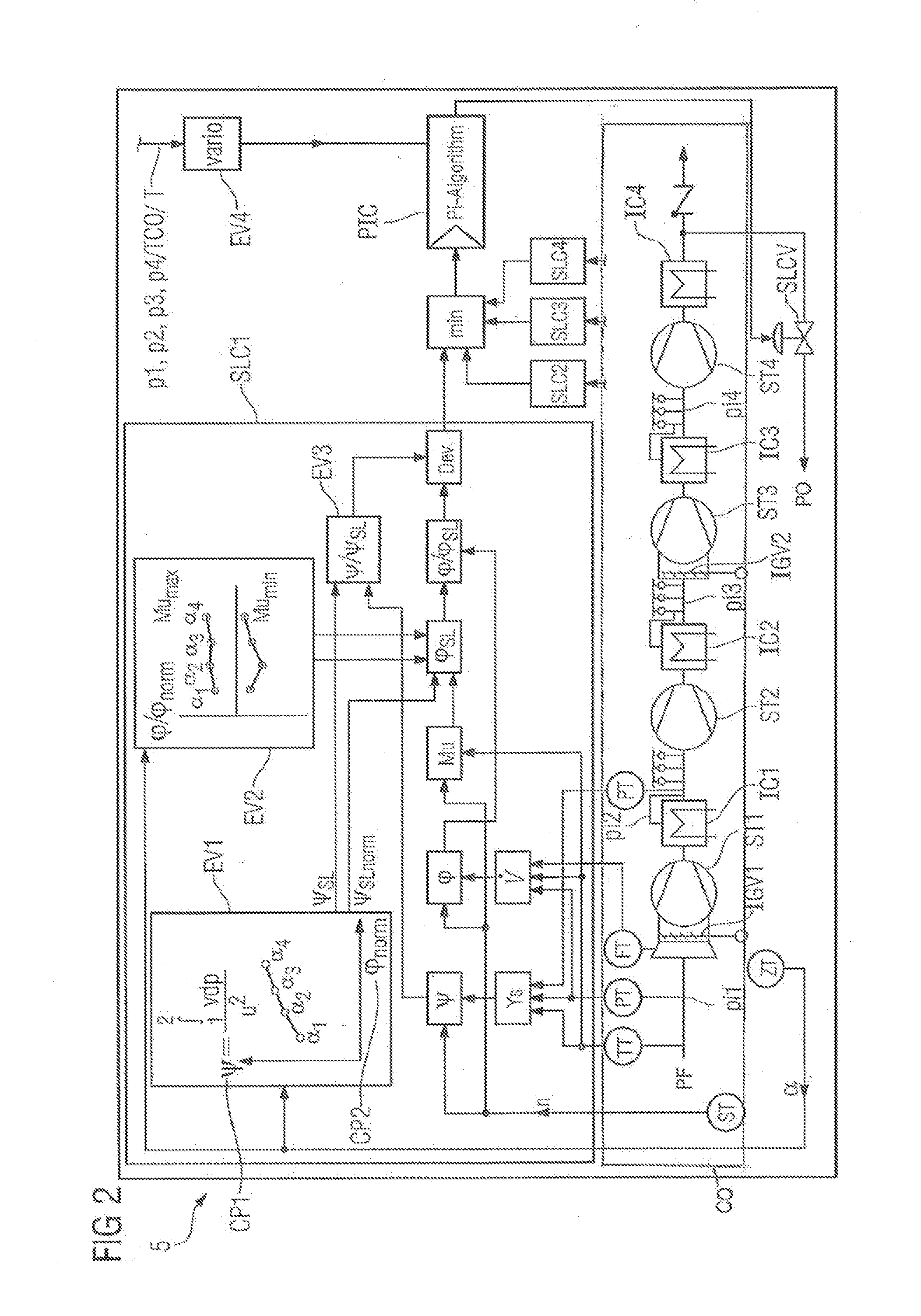

[0031]FIG. 2 shows a diagrammatic illustration of the method according to the invention, applied to a compressor CO with four stages ST1, ST2, ST3, ST4. The designations of FIG. 1 are to be applied to FIG. 2 to denote the same elements (substantially the compressor line which is the subject matter of the invention). At the first stage ST1 and the third stage ST3, the compressor CO in each case has an adjustable inlet guide vane apparatus IGV1, IGV3. An intercooler IC1 to IC4 (the intercooler IC4 of the last stage ST4 is actually an aftercooler, but this distinction is not made in the sequence for reasons of simplification) is provided in each case between the stages ST1 to ST4 and after the last stage ST4.

[0032]The compressor CO delivers a fluid PF, the volumetric flow of which is determined by means of a differential pressure measurement FT. The inlet pressure pi1-pi4 is determined at the inlet of each stage ST1 to ST4 by means of a pressure measurement PT. In addition, the inlet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com