Catalytic cracking process for biofeeds

a biofeed and catalytic cracking technology, applied in the field of catalytic cracking of biofeeds, can solve the problems of high operating cost, inability to efficiently make ethanol, and inability to meet the requirements of high-temperature corn and other crops, and achieve the effect of high distillate selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

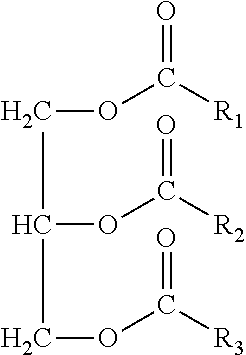

[0039]A process of catalytically cracking a feedstock comprising a biocomponent which comprises contacting a feedstock comprising a biocomponent with a catalytic cracking catalyst comprising a basic metal oxide on a porous oxide support at an elevated cracking temperature to eliminate oxygen from the biocomponent to form cracked hydrocarbon residues.

embodiment 2

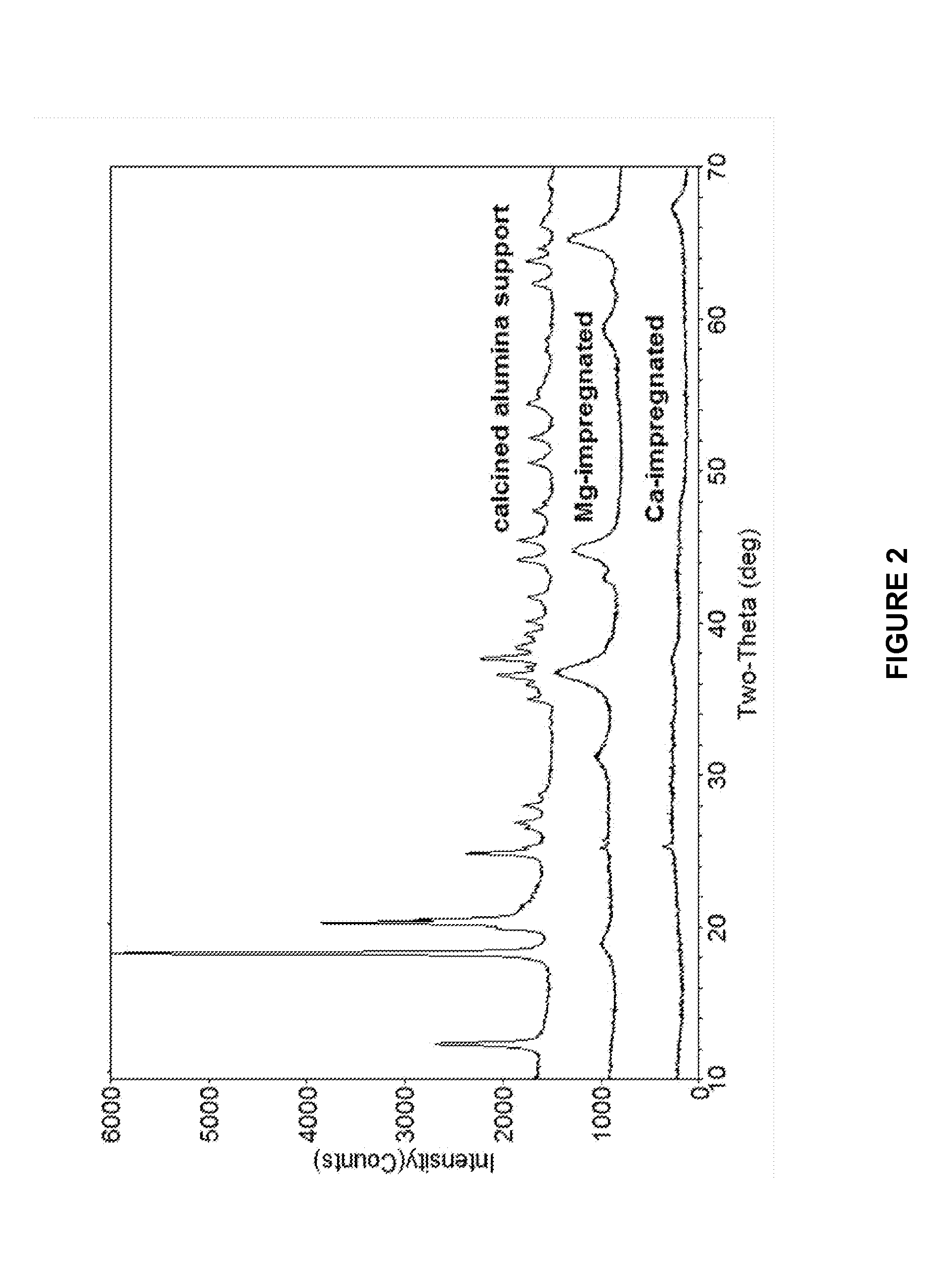

[0040]A process according to embodiment 1, wherein the basic metal oxide comprises an oxide of a metal of Group 2 of the Periodic Table (IUPAC).

embodiment 3

[0041]A process according to any prior embodiment, wherein the basic metal oxide is calcium or magnesium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com