Flame treatment of a substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

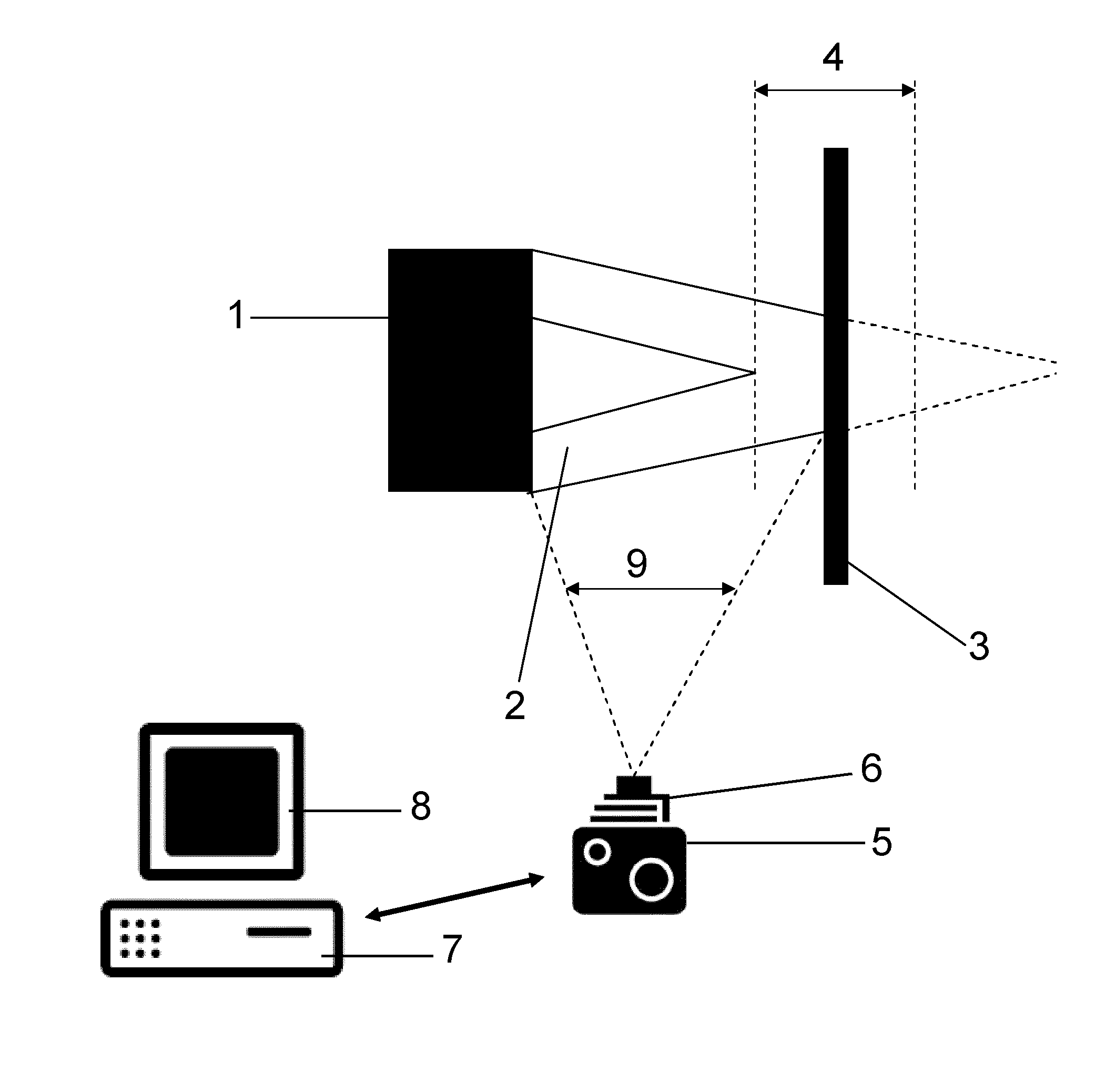

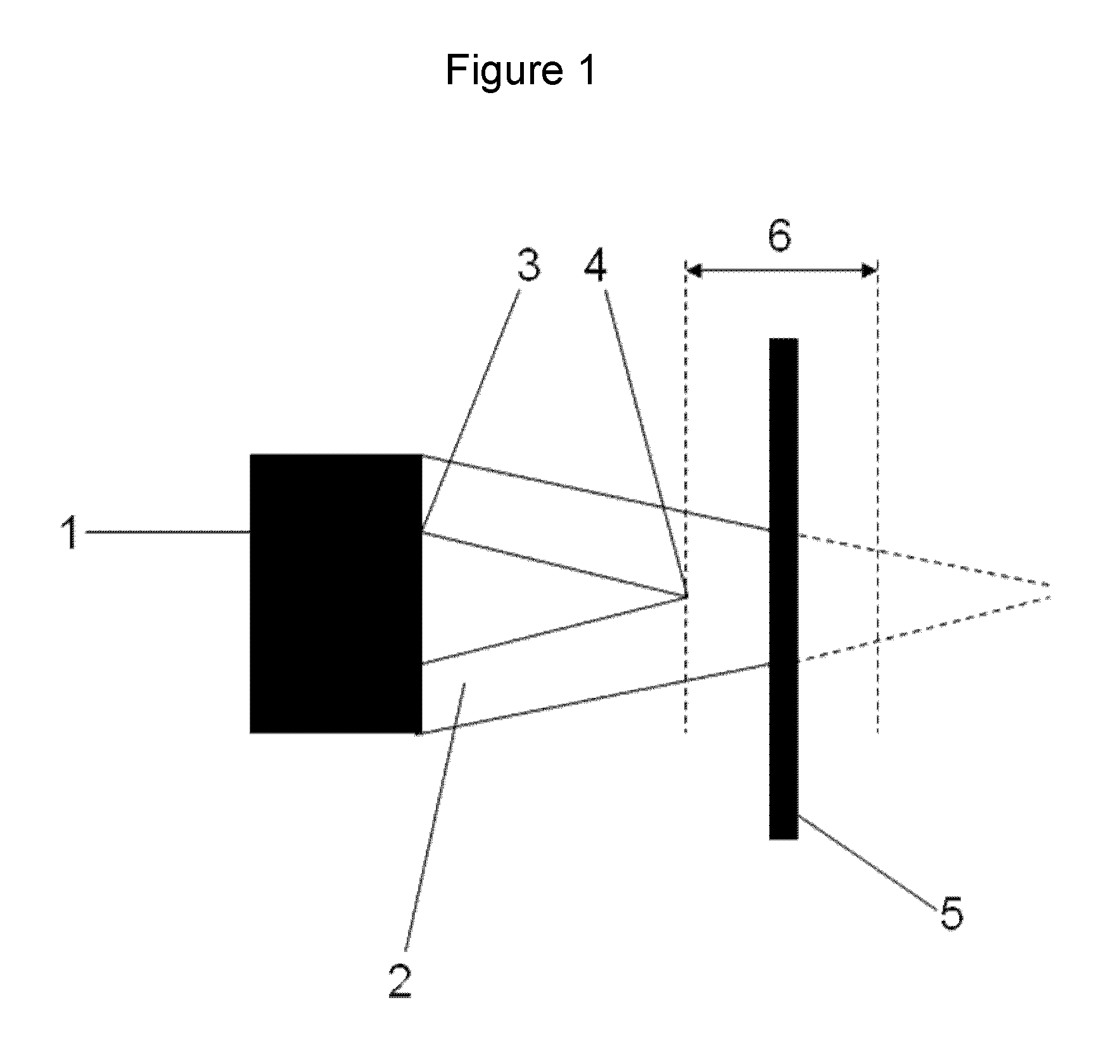

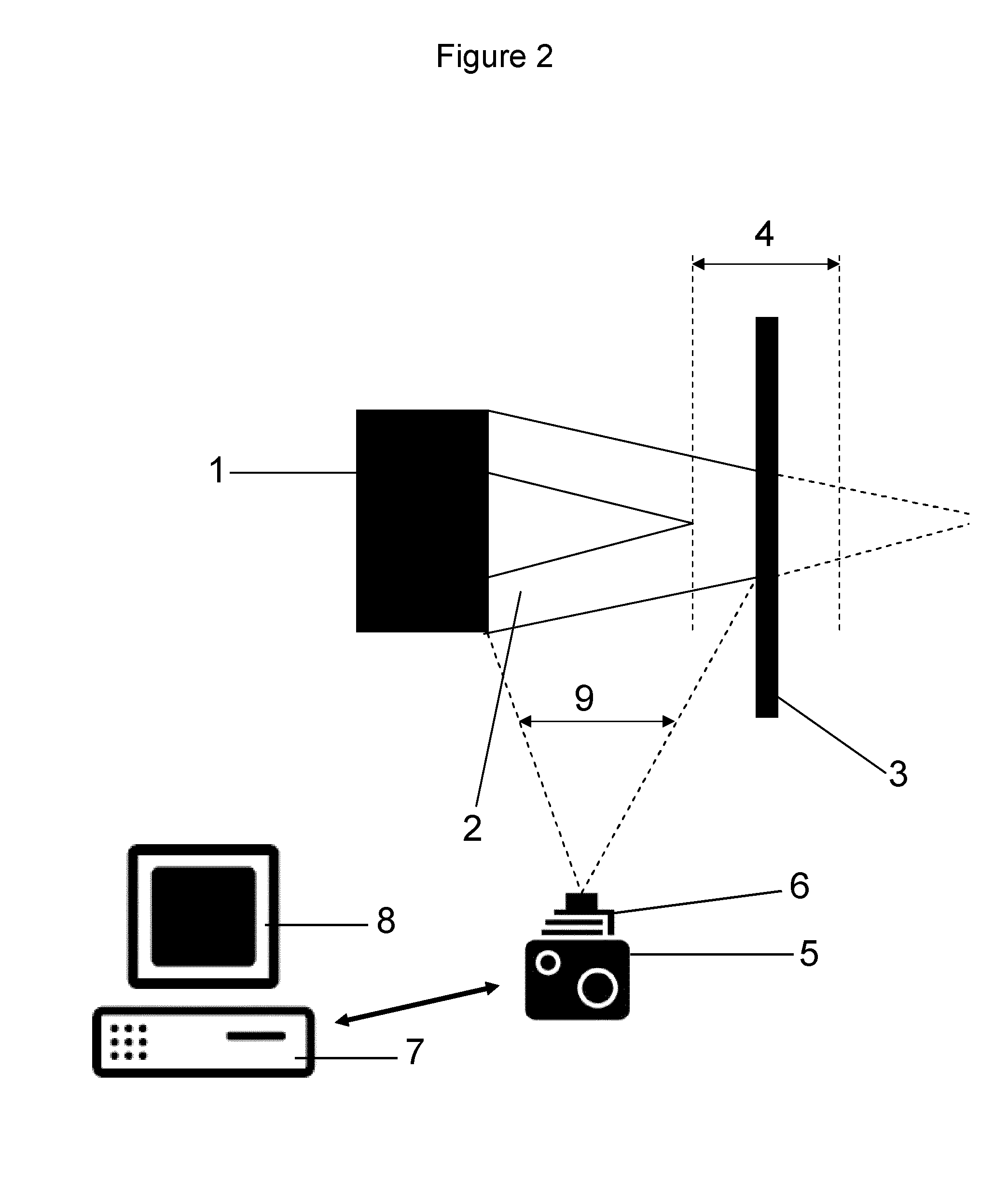

[0011]There are many factors affecting the flame treatment of a substrate. Some important parameters are gas flow, gas type, fuel mixture (mixture of fuel and oxygen, such as air), the distance between the burner and the substrate, the angle between the burner and the substrate, and the speed of the web substrate. Naturally it is preferred if many of the parameters are kept constant but normally this is not possible due to factors such as clogging of part of the burner nozzle, affecting the gas flow; variations in the fuel mixture; and variation of the line speed (the line transporting the substrate). According to the present invention any fuel and mixture of different compatible fuels may be used, non-limiting examples thereof are natural gas, liquid petroleum gas (LPG) and methane. The fuel mixture is normally a mixture between one or more fuel(s) and oxygen. Air is often used as the oxygen source and the air-fuel ratio is often expressed as percent excess combustion air. As an ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com