Controlled gravity feed shelf system

a shelf system and gravity technology, applied in the field of shelves, can solve the problems of product not being able to pass the front edge, product not being able to feed forward, and being difficult to restock and/or remove products from shelves,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

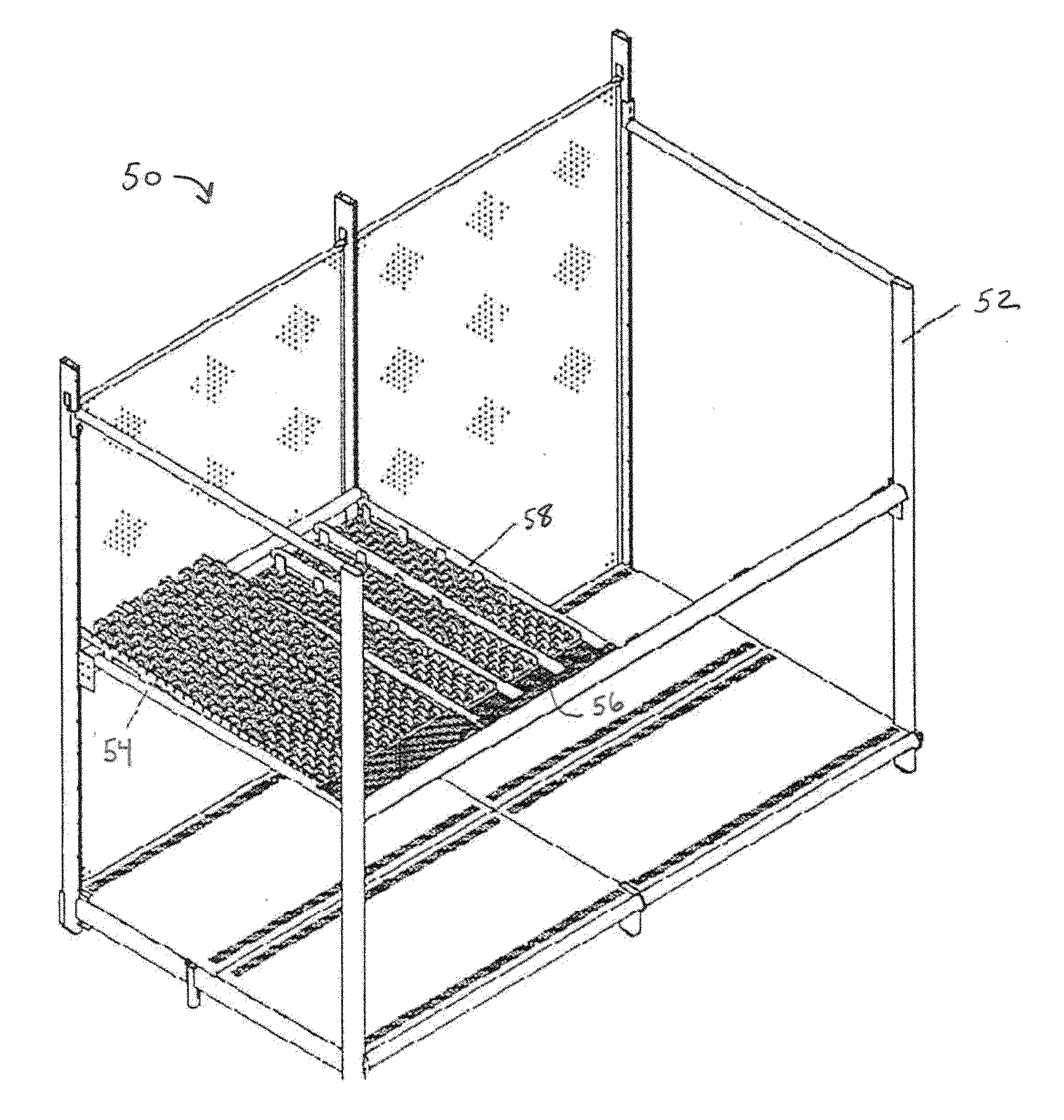

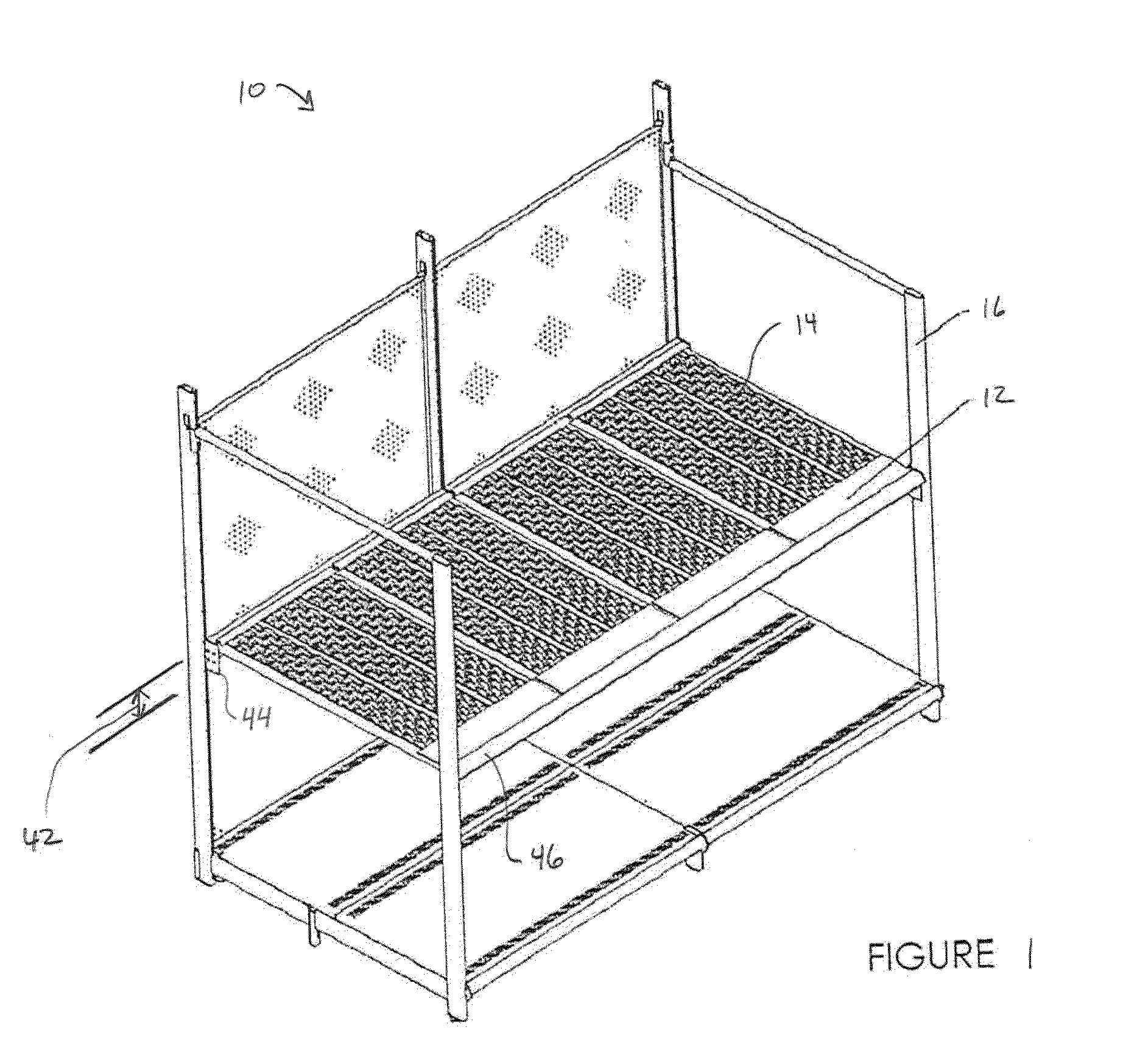

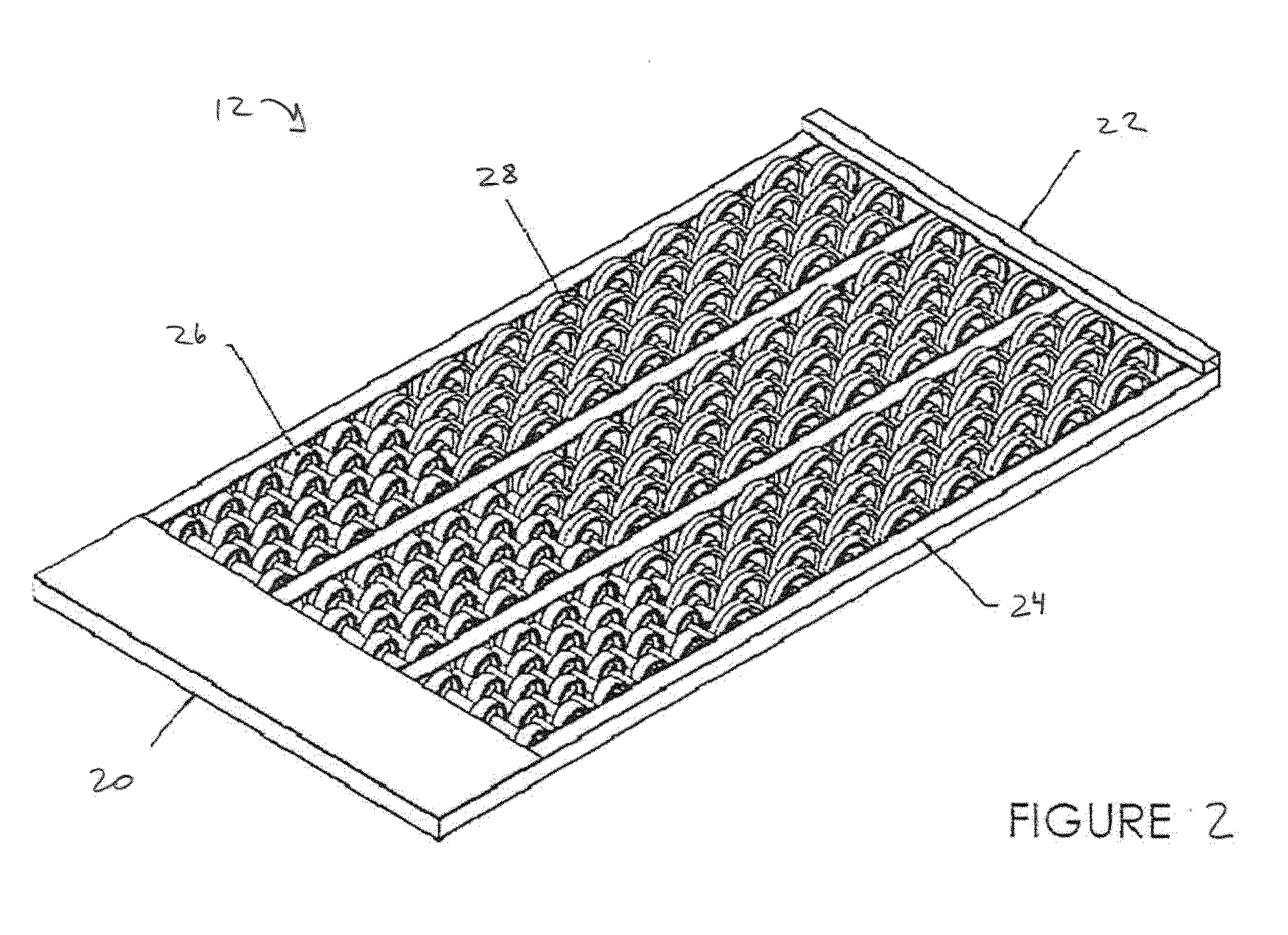

[0012]An embodiment of the controlled gravity feed shelf system of the present invention is indicated in general at 10 in FIG. 1. The gravity feed shelf system 10 features a number of shelf inserts 12 that, as explained in greater detail below, feature a roller surface 14 with rollers sized to control the feed of products placed thereon. The system includes a retail gondola framework 16 upon which the shelf inserts 12 are mounted. While FIG. 1 shows four separate inserts mounted on the gondola framework, any alternative number of the inserts featuring alternative sizes may be used instead.

[0013]In accordance with the present invention, for an applied load (product weight), a larger diameter roller will feed products more consistently than a smaller diameter roller at reduced shelf angles. The shelf inserts 12 of the present invention each provide a combination of larger diameter rollers at the rear of the shelf to consistently initiate the forward motion of products stocked on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com