Metal Tooth For Zipper

a metal tooth and zipper technology, applied in the direction of snap fasteners, slide fasteners, press-button fasteners, etc., can solve the problems of unsmooth closing or opening of metal zippers, and achieve the effect of prolonging the life of metal zippers, avoiding vibration, and enhancing the engagement of zipper tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

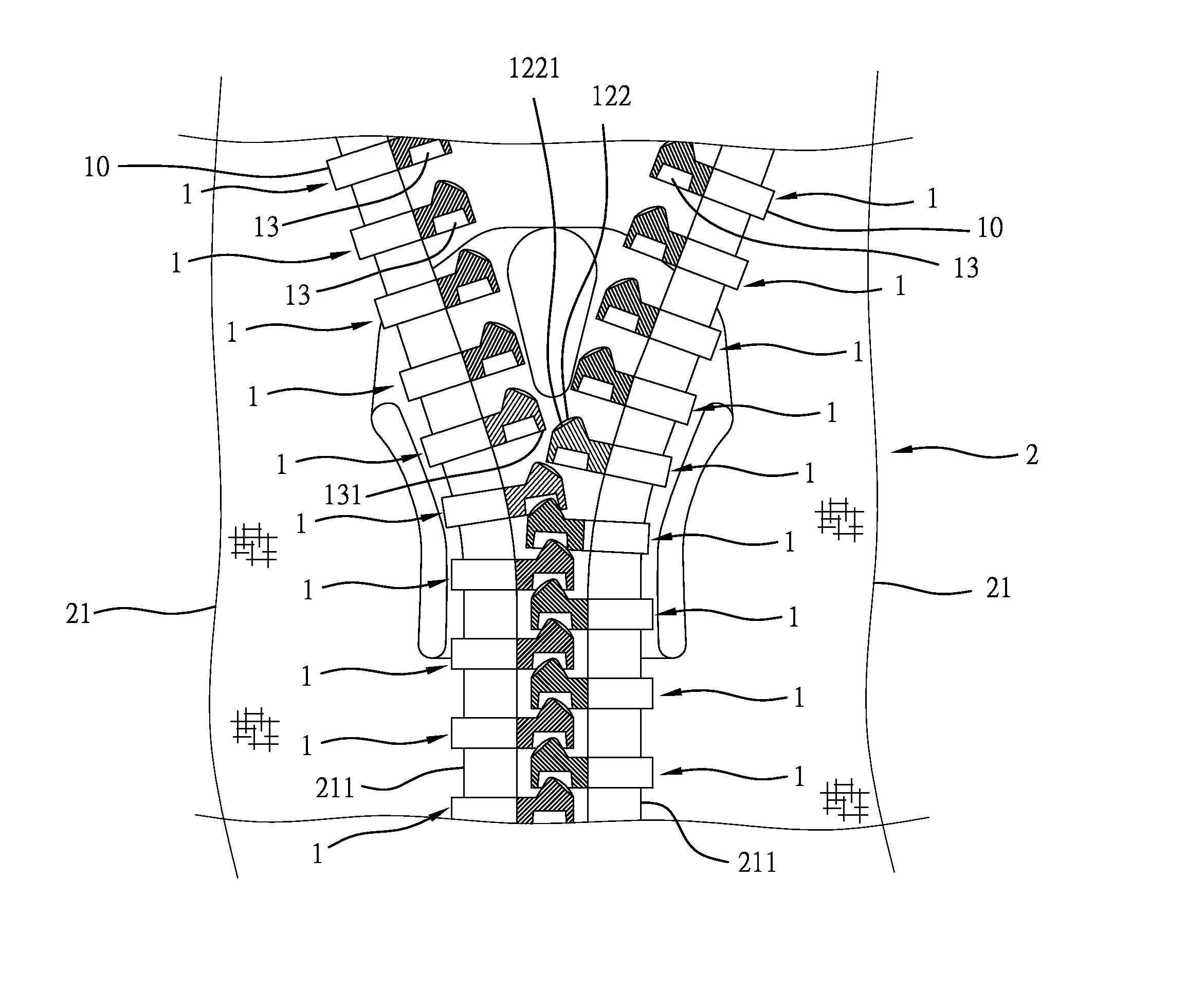

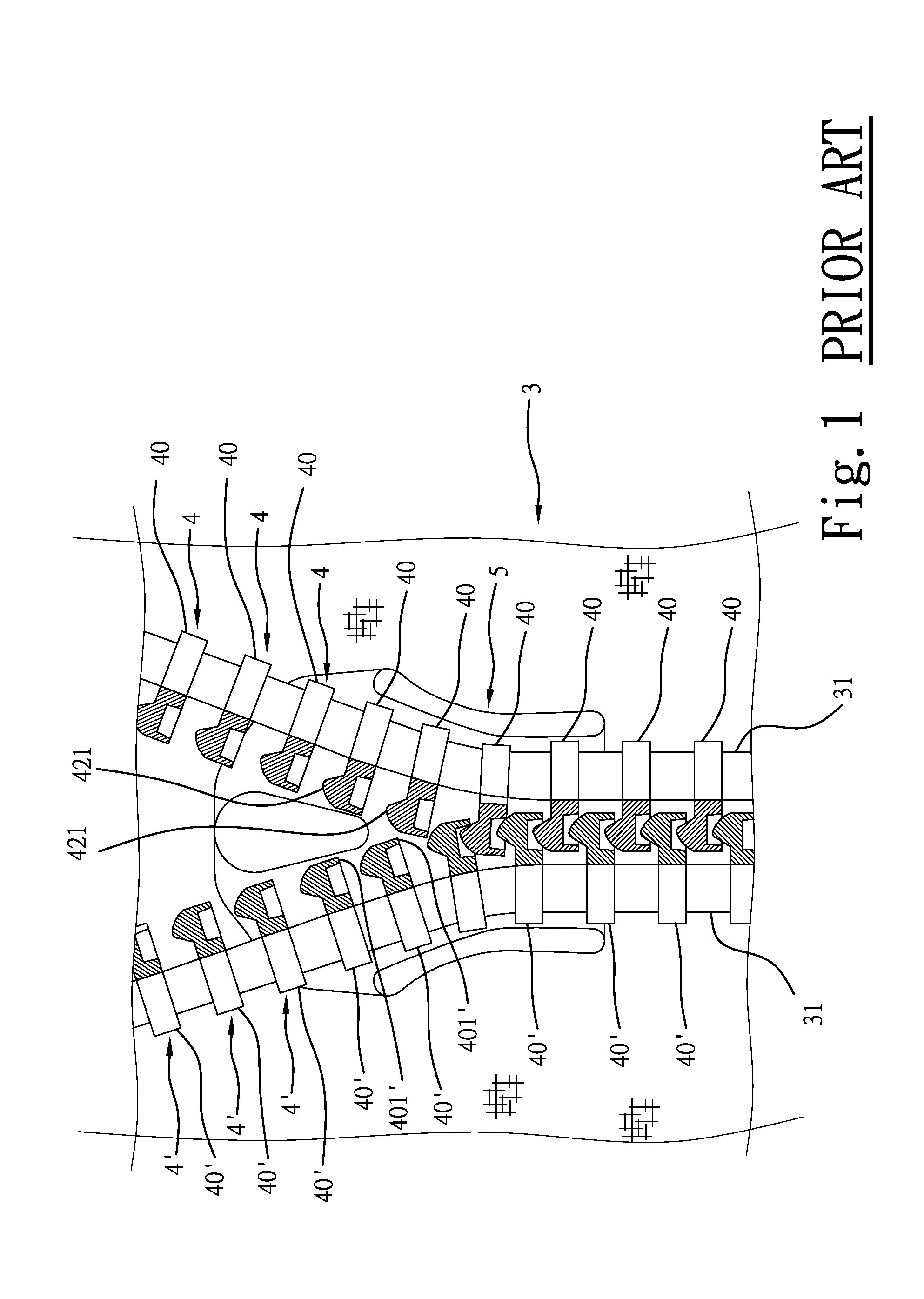

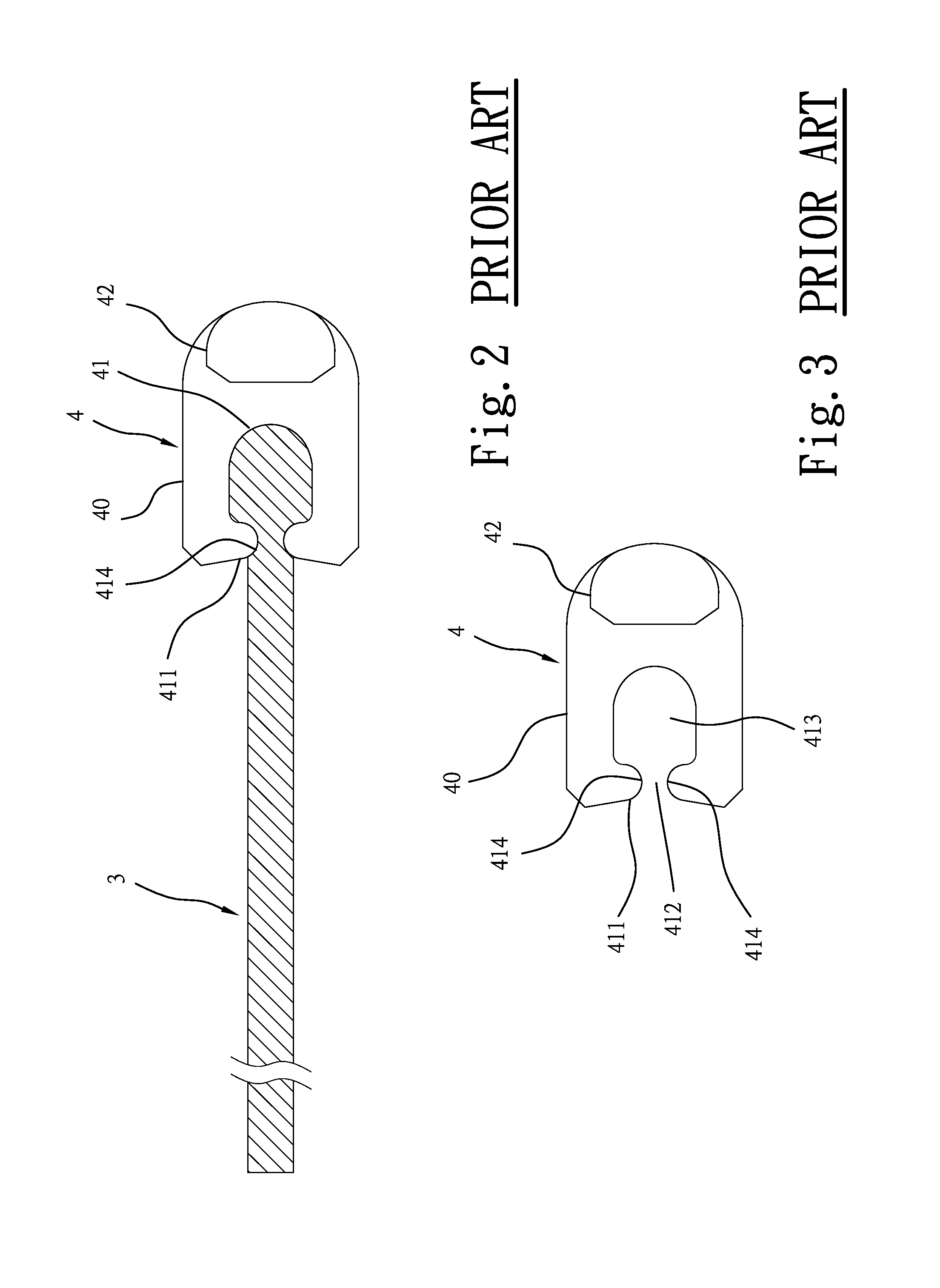

[0018]Referring to FIGS. 4˜7, a metal zipper 2 (see FIG. 7) is shown, comprising two zipper tapes 21 each having a longitudinal inner edge 211, two series of metal teeth 1 respectively and transversely affixed to the zipper tapes 21 and spaced along the respective longitudinal inner edges 211 in a staggered manner. By means of pulling a slide (not shown) in one direction, the two series of metal teeth 1 can be interlocked, forming a chain. Each metal tooth 1 comprises a base 10, a mounting hole 11 transversely cut through one end, namely, the inner end of the base 10 on the middle (see FIG. 6), and a protruding tooth head 12 protruded from one lateral side of an opposite end, namely, the outer end of the base 10. The mounting hole 11 has an outer open end 111, an inner close end 115, a first neck 112 spaced between the outer open end 111 and the inner close end 115, a second neck 114 spaced between the first neck 112 and the inner close end 115, and a flank portion 113 defined betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com