Refrigerant system with cascaded circuits and performance enhancement features

a cascaded circuit and refrigerant technology, applied in the field of cascaded refrigerant systems, can solve the problems of refrigerant systems utilizing cosub>2/sub>as a refrigerant that does not always operate at the efficiency level of traditional refrigerant systems, and none of the above-referenced enhancement features have been incorporated into the cascaded refrigerant systems to achieve the effect of enhancing the operation of the cascaded r

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

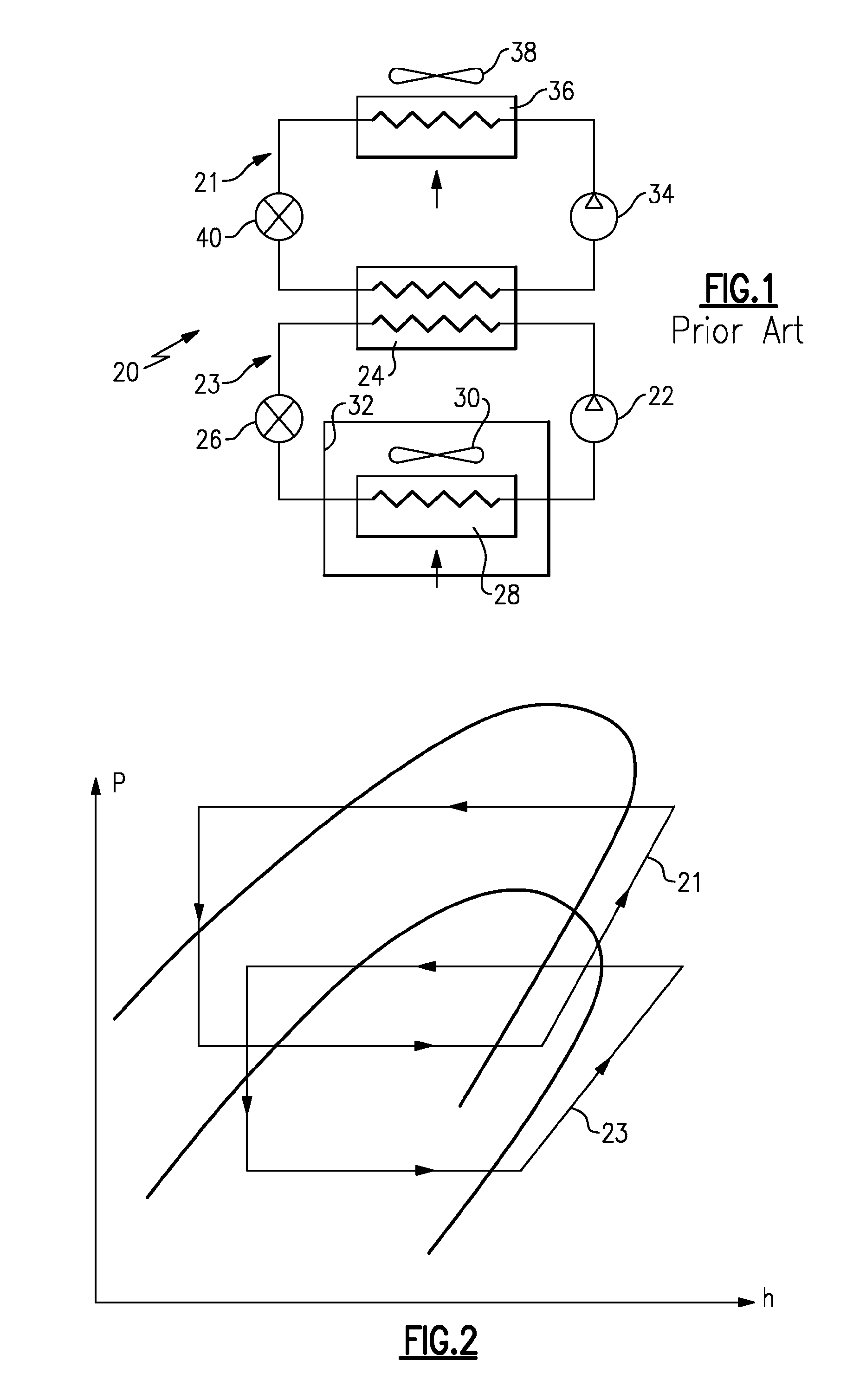

[0022]FIG. 1 shows a prior art refrigerant system 20 incorporating two cascaded circuits 21 and 23. A lower stage circuit 23 includes a compressor 22 delivering a compressed refrigerant into a refrigerant-to-refrigerant heat exchanger 24. Heat exchanger 24 is preferably positioned outside of an environment 32 to be conditioned. Refrigerant passes from the heat exchanger 24 through an expansion device 26, and to an indoor heat exchanger 28. As known, a fan 30 blows air over external surfaces of the indoor heat exchanger 28 and delivers that conditioned air into the environment 32. The lower stage circuit 23 would normally be charged with a refrigerant that would operate in a subcritical region. One such refrigerant that can be used for this circuit would be CO2 refrigerant that, while in the lower cascaded circuit, would still be in the subcritical region. If this same CO2 refrigerant would have been used in the upper cascaded circuit, it is likely to operate at transcritical regime....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com